Program and method for controlling pressure of nitrogen injection production increase coal bed gas

A technology of coalbed methane and nitrogen injection, applied in the direction of fluid pressure control, non-electric variable control, control/regulation system, etc., can solve problems such as impracticability and incorrectness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in combination with specific embodiments.

[0030] The "nitrogen gas" mentioned in the present invention refers to high-purity nitrogen gas and a gas whose main component is nitrogen gas. High-purity nitrogen is a gas with a nitrogen volume percentage greater than 95%. The gas with nitrogen as the main component is a mixed gas with a nitrogen volume percentage greater than 50%, such as chimney gas and blast furnace gas.

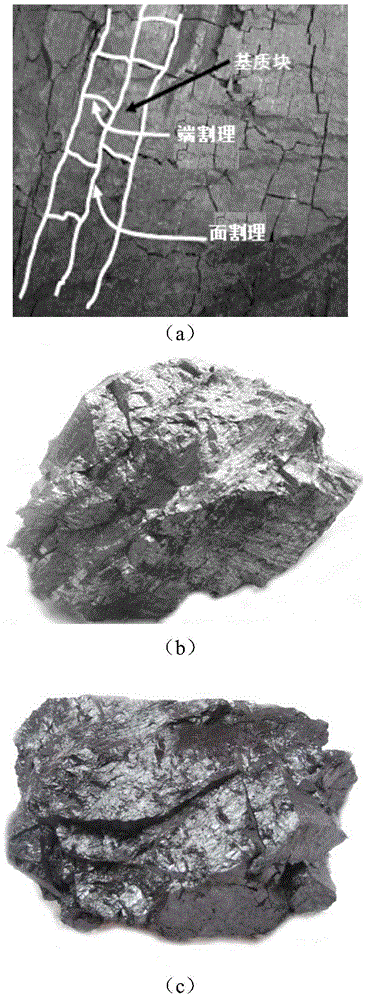

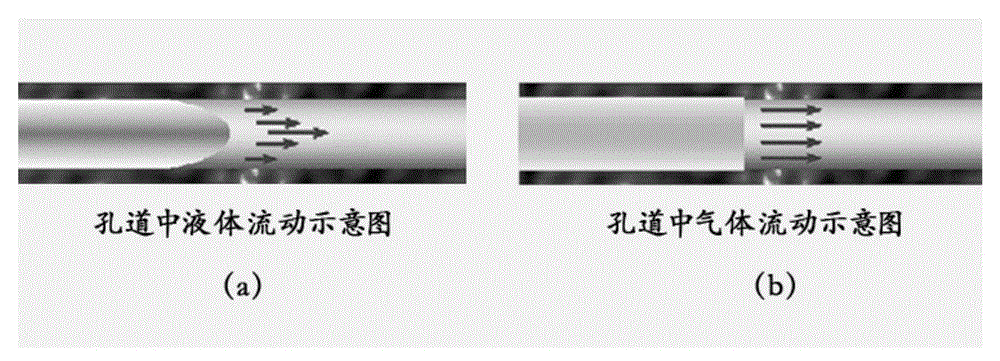

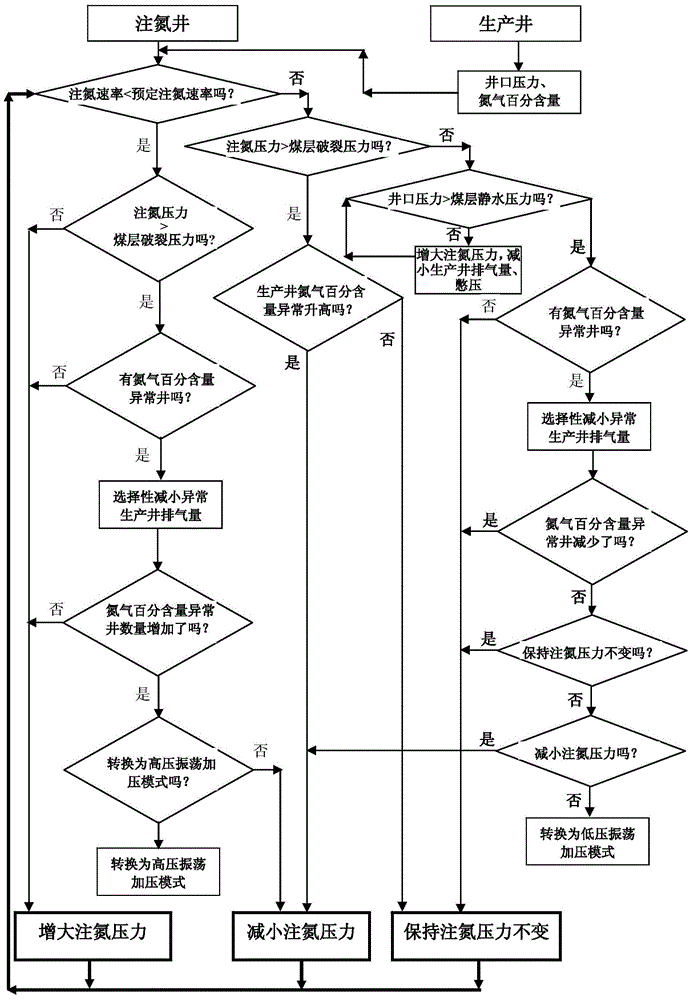

[0031]The key to increasing coalbed methane production by nitrogen injection is how to make the injected nitrogen enter the coal seam, sweep through the entire coal seam between the nitrogen injection well and the production well, make nitrogen enter the coal seam micropores, promote the desorption of the adsorbed coalbed methane, and drive the desorption The final free state coalbed methane is sent to production wells. This "promoting decomposition and flooding" effect promotes the desorption of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com