A chip bonding method for gaas MMIC thinning process

A technology of bonding and process, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of increasing raw materials, increasing process steps, etc., and achieve the effect of solving the problem of debris, leveling the suspension coating, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

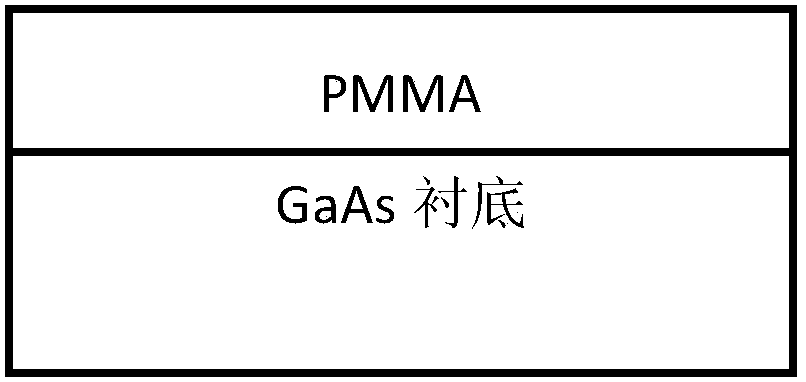

[0035] 1) Spread electron beam photoresist on the front side of GaAs substrate, such as figure 1 Shown. The electron beam photoresist is PMMA-A11 photoresist, the speed of the homogenizing table is 1500 revolutions / min, the time is 1 min, the number of leveling is 3 times, the thickness of leveling is about 5um, and the baking condition is 180℃ hot The plate is heated for 3 minutes.

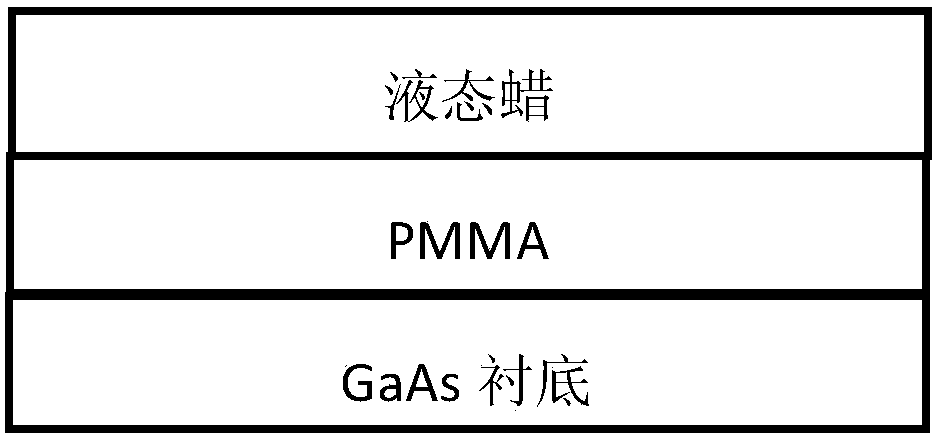

[0036] 2) Spread liquid wax evenly on the electron beam photoresist, such as figure 2 As shown; where: the liquid wax is prepared according to the following method: Weigh Crystalbond 509 strong adhesive and acetone according to the ratio of 20g:50ml, put them in the vessel, seal the vessel, and place it in a water bath at 60°C until Crystalbond 509 strong adhesive is completely dissolved and ready. When leveling liquid wax, the rotation speed of the leveling table is 1500 rpm, the time is 15sec, the number of leveling is 5, and the thickness of leveling is about 5um.

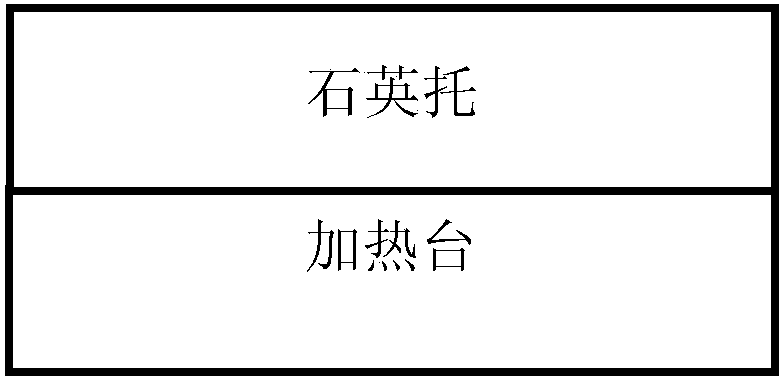

[0037] 3) Place the quartz h...

Embodiment 2

[0044] Repeat Example 1, except that the liquid wax is prepared as follows: Weigh Crystalbond 509 strong adhesive and acetone at a ratio of 10g:40ml, place them in a container, seal the container, and place it in a water bath at 50°C. Until Crystalbond 509 strong adhesive is completely dissolved, it is ready.

Embodiment 3

[0046] Repeat Example 1, except that the liquid wax is prepared as follows: Weigh Crystalbond 509 strong adhesive and acetone according to the ratio of 30g:60ml, put them in a container, seal the container, and place it in a water bath at 50°C. Until Crystalbond 509 strong adhesive is completely dissolved, it is ready.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com