Cartridge type hollow fiber membrane module

A fiber membrane and hollow technology, applied in the field of cylindrical hollow fiber membrane modules, can solve the problems of small effective membrane area and insufficient cost advantage, and achieve the effect of ensuring steam sterilization and inhibiting damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

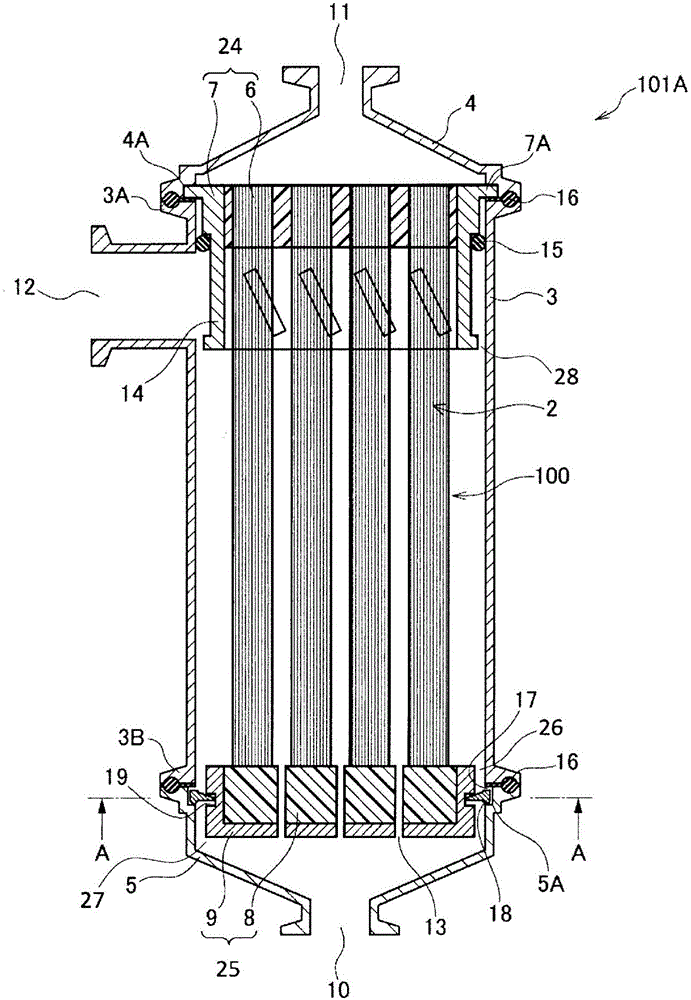

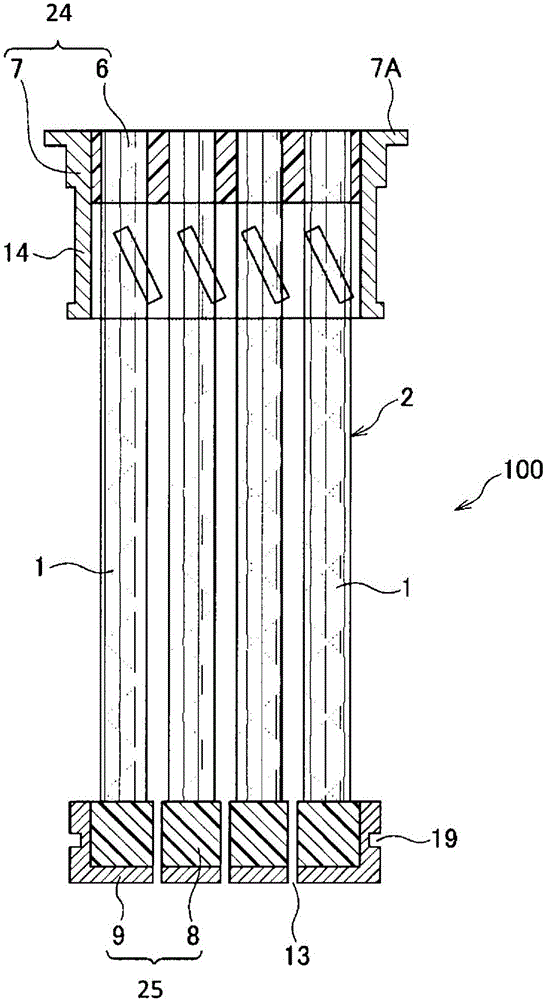

[0050] The configuration of the cartridge-type hollow fiber membrane module 101A according to the first embodiment of the present invention will be described with reference to the drawings. figure 1 is a schematic longitudinal sectional view of a cartridge-type hollow fiber membrane module 101A according to the first embodiment of the present invention, figure 2 is a schematic cross-sectional view of the hollow fiber membrane cartridge 100 .

[0051] The cartridge type hollow fiber membrane module 101A according to the first embodiment of the present invention has the following configuration: a casing; a plurality of hollow fiber membranes 1 accommodated in the casing; The first end of the membrane is bundled in an open state; the second potting part 25 is used to bundle the second end of the hollow fiber membrane 1 in a sealed state; the fixing part is used to bind the first potting part 24 Detachably fixed to the aforementioned casing; a sealing portion, which liquid-tight...

no. 2 Embodiment approach

[0128] Figure 8 is a schematic longitudinal sectional view of a cartridge type hollow fiber membrane module 101B according to the second embodiment, Figure 9 yes Figure 8 The BB line profile. In addition, in description of 2nd Embodiment, the same code|symbol is attached|subjected to the same member as 1st Embodiment, and the description is abbreviate|omitted.

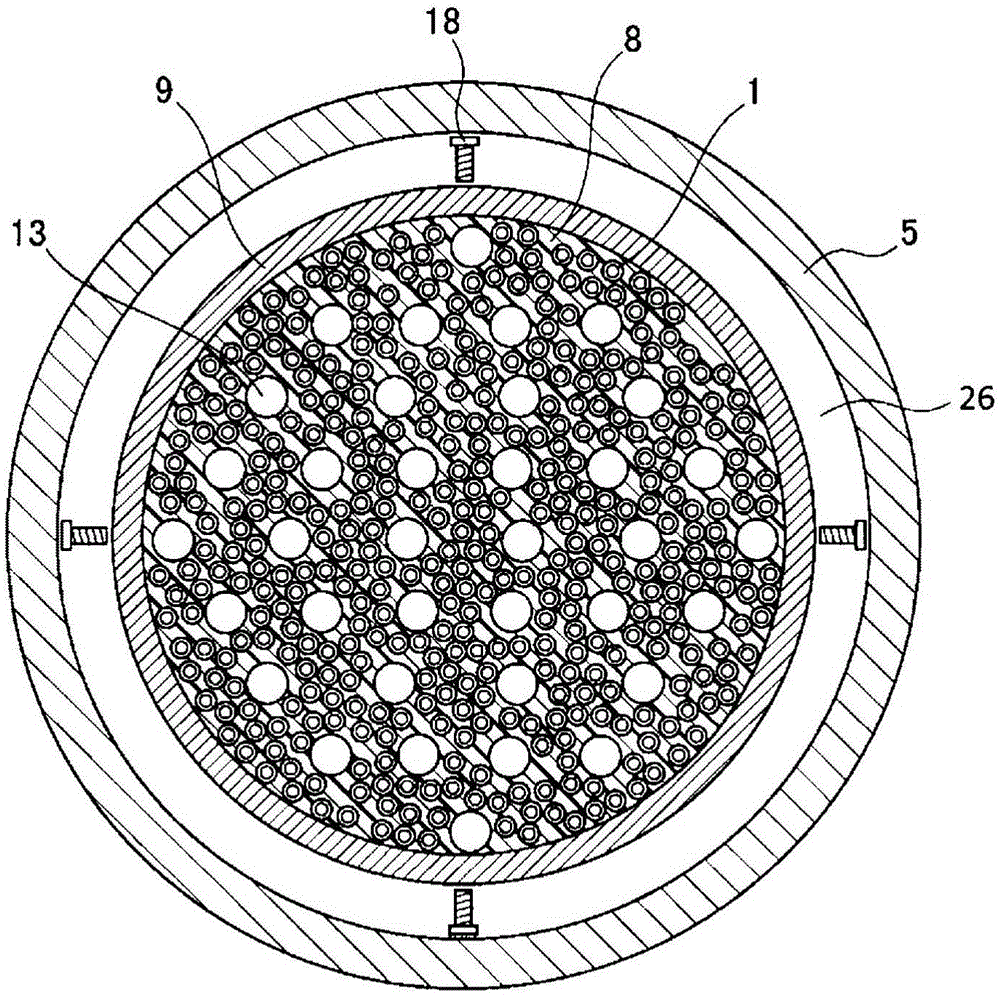

[0129] In the cartridge type hollow fiber membrane module 101B according to the second embodiment, the lower cover 5 is provided with a pin 18 as a holding portion. pin 18 as Figure 8 and Figure 9 As shown in , it is set to protrude from the inner side surface of the lower cover 5 . In addition, the second potting part 25 is provided with a second holding groove 19 on the side surface of the second end case 9, and the second potting part 25 can be held by inserting the pin 18 into the second holding groove 19. The method of forming the pin 18 is not particularly limited, and may be formed by cutting or weldi...

no. 3 Embodiment approach

[0149] (Third Embodiment)

[0150] Figure 13 is a schematic longitudinal sectional view of a cartridge-type hollow fiber membrane module 101C according to the third embodiment, Figure 14 yes Figure 13 The CC line profile. In addition, in description of 3rd Embodiment, the same code|symbol is attached|subjected to the same member as 1st Embodiment, and the description is abbreviate|omitted.

[0151] In the cartridge type hollow fiber membrane module 101C according to the third embodiment, as in the first embodiment, a first retainer is provided at a position of the second potting part 25 facing the outer peripheral surface of the second end case 9 . The groove 17 is provided with a second holding groove 19 at a position facing the first holding groove 17 on the outer peripheral surface of the second end housing 9 . In the third embodiment, the first holding groove 17 is continuously formed on the inner peripheral surface of the case, and similarly, as Figure 15 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com