Preparation method of zirconia all-ceramic post/nail for dental restoration

A zirconia, dental technology, applied in the direction of dental preparations, dentistry, dental prosthesis, etc., can solve the problems of easy falling off of fillings, achieve outstanding bonding effect, reduce tooth tissue damage, and have broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the drawings and embodiments.

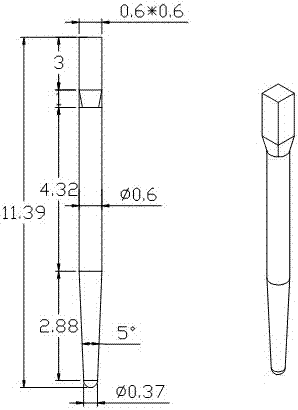

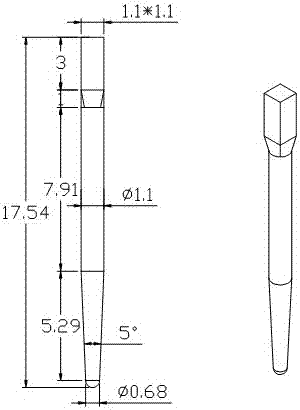

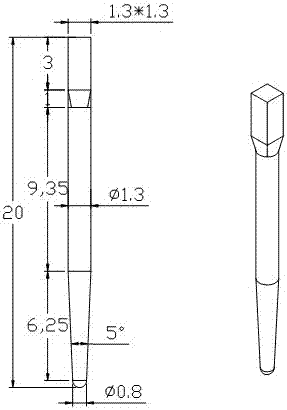

[0032] Such as Figure 1-4 Shown.

[0033] A preparation method of zirconia all-ceramic post / nail for dental restoration, which comprises the following steps:

[0034] First, collect the size parameters of the piles / nails required for the repair site;

[0035] Secondly, make corresponding plaster models of piles / nail wax sticks according to the collected size parameters;

[0036] Third, input the data of the plaster model into the CAD / CAM database;

[0037] Fourth, use CAD / CAM technology to control mechanical processing equipment to cut and process zirconium dioxide blocks of the required shape. The shrinkage rate (generally 20%) during the sintering process of the zirconium dioxide blocks should be taken into account during the cutting process. The corresponding size is correspondingly enlarged (enlarged to 125% of the actual size);

[0038] Fifth, put the cut zirconium dioxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com