Preparation method of Zn-Ce-ZrO2 catalytic material

A technology of zn-ce-zro2, ——zn-ce-zro2, applied in the field of new nano-catalytic materials, can solve the problem that the reactor is susceptible to corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

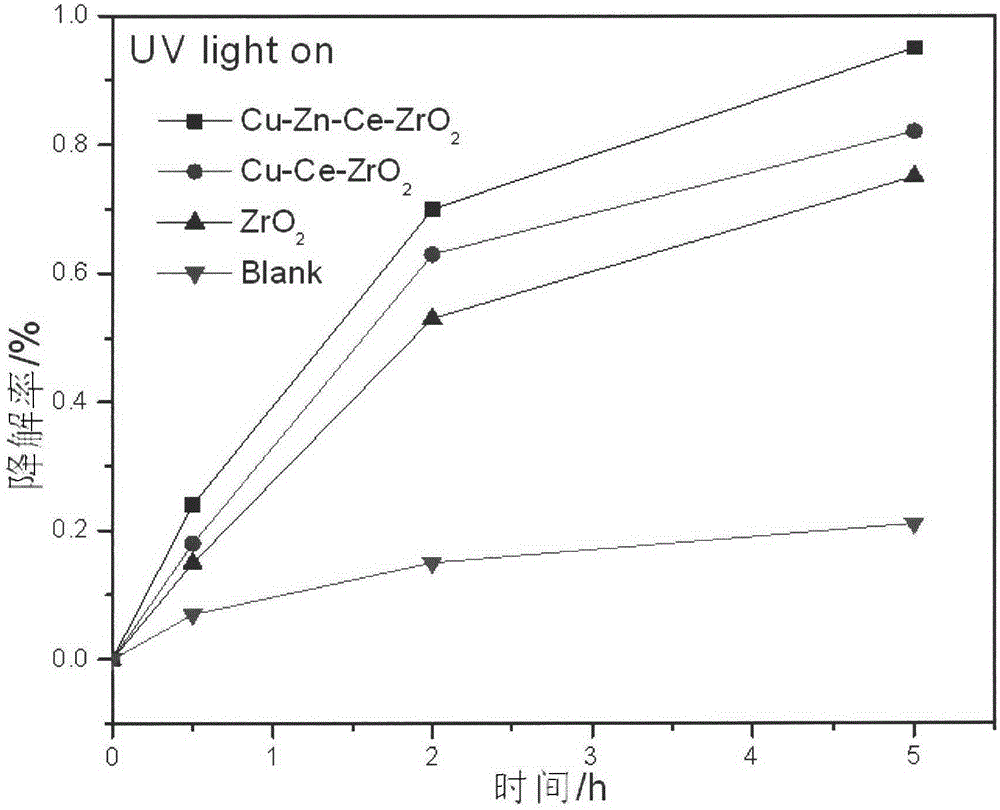

[0024] Cu-Zn-Ce-ZrO 2 Preparation of catalytic materials:

[0025] ①. Weigh 9.6675g of ZrOCl 2 ·8H 2 O, 1.0000g of C 19 h 42 BrN, 0.3001g of CuCl 2 2H 2 O, 0.2400g of ZnCl 2 and 0.7116g of Ce(SO 4 ) 2 4H 2 Pour O into a beaker with a capacity of 150mL, add 100mL distilled water, and stir.

[0026] ②. Add a small amount of absolute ethanol, and then dropwise add 28% ammonia water until the pH value of the solution is 7-8, then stop the dropwise addition.

[0027] ③ Stir with a magnetic stirrer for 2 hours and ultrasonically for 1 hour to mix evenly.

[0028] ④. Pour the solution into a 100mL reactor (note that the filling volume should not exceed 3 / 4 of the total volume), seal it, and put it in an oven with the temperature set at 75°C for hydrothermal reaction. Take it out after 24 hours.

[0029] ⑤. After the temperature of the reaction kettle is cooled down, take out the reaction product, wash it with distilled water and 95% ethanol several times until the AgNO 3...

Embodiment 2

[0033] Cu-Zn-ZrO 2 Preparation of catalytic materials:

[0034] ①. Weigh 9.6675g of ZrOCl 2 ·8H 2 O, 1.0000g of C 19 h 42 BrN, 0.4501 g of CuCl 2 2H 2 O and 0.3600 g of ZnCl 2 Pour into a beaker with a capacity of 150mL, add 100mL of distilled water, and stir.

[0035] ②. Add a small amount of absolute ethanol, and then dropwise add 28% ammonia water until the pH value of the solution is 7-8, then stop the dropwise addition.

[0036] ③ Stir with a magnetic stirrer for 2 hours and ultrasonically for 1 hour to mix evenly.

[0037] ④. Pour the solution into a 100mL reactor (note that the filling volume should not exceed 3 / 4 of the total volume), seal it, and put it in an oven with the temperature set at 75°C for hydrothermal reaction. Take it out after 24 hours.

[0038] ⑤. After the temperature of the reaction kettle is cooled down, take out the reaction product, wash it with distilled water and 95% ethanol several times until the AgNO 3 Solution with no detectable Cl ...

Embodiment 3

[0042] Cu-Ce-ZrO 2 Preparation of catalytic materials:

[0043] ①. Weigh 9.6675g of ZrOCl 2 ·8H 2 O, 1.0000g of C 19 h 42 BrN, 0.450 lg of CuCl 2 2H 2 O and 1.0674g of Ce(SO 4 ) 2 4H 2 Pour O into a beaker with a capacity of 150mL, add 100mL distilled water, and stir.

[0044] ②. Add a small amount of absolute ethanol, and then dropwise add 28% ammonia water until the pH value of the solution is 7-8, then stop the dropwise addition.

[0045] ③ Stir with a magnetic stirrer for 2 hours and ultrasonically for 1 hour to mix evenly.

[0046] ④. Pour the solution into a 100mL reactor (note that the filling volume should not exceed 3 / 4 of the total volume), seal it, and put it in an oven with the temperature set at 75°C for hydrothermal reaction. Take it out after 24 hours.

[0047] ⑤. After the temperature of the reaction kettle is cooled down, take out the reaction product, wash it with distilled water and 95% ethanol several times until the AgNO 3 Solution with no detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com