Method and system for recycling crystallized salt resources in high-salt-content wastewater zero discharge

A technology for resource recovery and saline wastewater, applied in chemical instruments and methods, alkali metal sulfite/sulfite, water pollutants, etc., can solve problems such as hindering zero discharge of high saline wastewater, and reduce operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

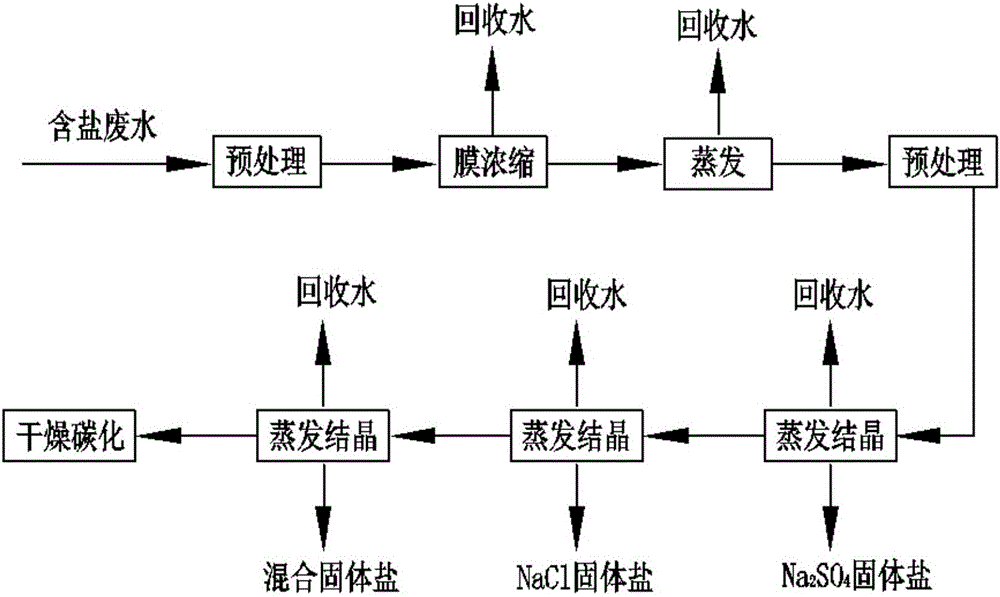

[0041] Such as figure 2 As shown, a system for recovering crystallized salt resources from highly saline wastewater with zero discharge includes a pretreatment system, a membrane concentration system and an evaporation crystallization system; the evaporation crystallization system includes sodium sulfate evaporation crystallization devices, chlorination The sodium evaporation crystallization device and the mixed salt evaporation crystallization device, the sodium sulfate evaporation crystallization device is composed of the first evaporation device and the first crystallizer in series, the sodium chloride evaporation crystallization device is composed of the second evaporation device and the second crystallizer in series, the mixed salt The evaporation and crystallization device is composed of a third evaporation device and a third crystallizer in series; the water outlet of the pretreatment system is connected to the water inlet of the membrane concentration system, and the w...

Embodiment 2

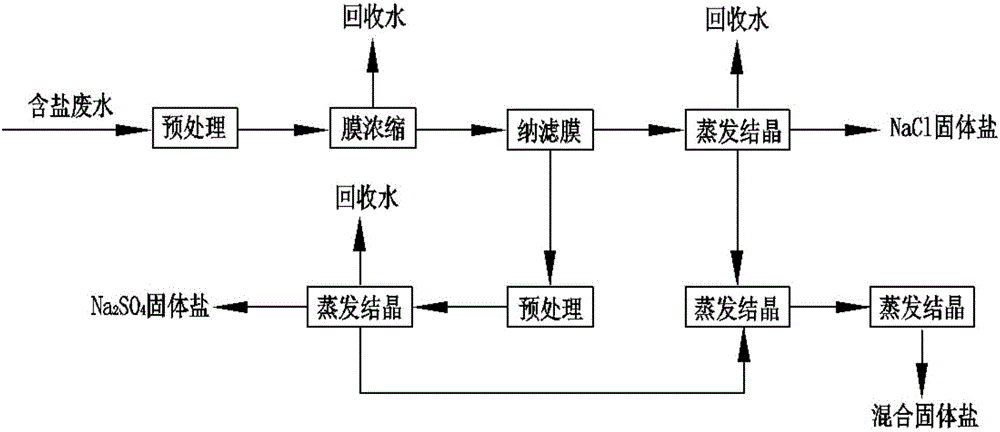

[0051] Such as image 3 As shown, a system for recovering crystalline salt resources from highly saline wastewater with zero discharge includes a pretreatment system, a membrane concentration system, a nanofiltration membrane system and an evaporative crystallization system; the evaporative crystallization system includes a sodium sulfate evaporative crystallization device, a chlorine The sodium chloride evaporation crystallization device, the mixed salt evaporation crystallization device, the sodium sulfate evaporation crystallization device and the sodium chloride evaporation crystallization device are connected in parallel to the mixed salt evaporation crystallization device; the sodium sulfate evaporation crystallization device is connected in series by the first evaporation device and the first crystallizer Composition, the sodium chloride evaporation and crystallization device is composed of the second evaporation device and the second crystallizer in series, and the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com