Half-sandwich cyclometalated ruthenium coordination compound, and preparation method and application thereof

A technology of coordination compound and cyclometallization, applied in the field of synthetic chemistry, can solve the problems of high cost, high reaction pressure and high production cost, and achieve the effects of low cost, simple operation and little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

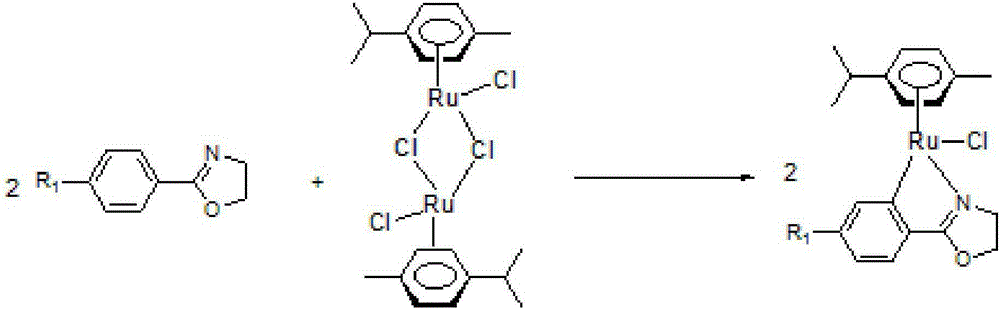

[0023] The present invention also provides a method for preparing the half-sandwich cyclometalated ruthenium complex described above, wherein the preparation method includes: under the condition of the presence of a protective gas, the compound shown in formula (B) The compound, dichloro(p-methylisopropylphenyl) ruthenium (II) dimer, base and solvent are mixed at a temperature of 80-110° C. for 15-20 hours to prepare a half-sandwich cyclometalated ruthenium complex compound;

[0024]

[0025] Among them, R 1 is Cl, Br or CH 3 .

[0026] Through the above technical scheme, the present invention reacts after mixing the compound shown in formula (B) and dichloro(p-methylisopropylphenyl) ruthenium (II) dimer, so that it can be synthesized in one step by a simple method A cyclometalated ruthenium complex with a semi-sandwich structure that exists stably in air.

[0027] Above-mentioned mixing method can be only simple mixing, and make it react in the mixing process, certainl...

Embodiment 1

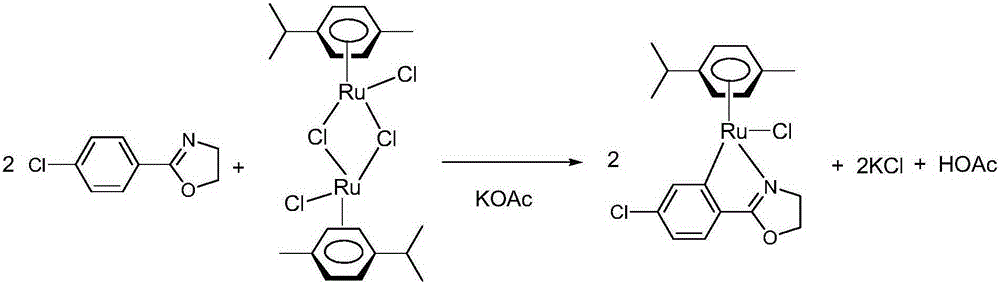

[0046] Put 1 mmol of dichloro(p-methylisopropylphenyl) ruthenium (II) dimer, 2.4 mmol of L1 and 4 mmol of potassium acetate into a 50 mL reaction tube, and take 25 mL of acetonitrile as a solvent. The above mixture was heated, stirred and refluxed for 20 hours, then cooled to room temperature. The solvent was then removed using a rotary evaporator, and the resulting solid was washed with diethyl ether. The product was recrystallized from ethyl acetate and dichloromethane and dried to give 811 mg of the green product 1a in 87% yield. The parameters of the proton nuclear magnetic spectrum and the carbon nuclear magnetic spectrum of the product made are: 1 HNMR (500MHz, CDCl 3 ,ppm): δ=8.09(s,1H),7.26(d,1H),6.96(d,1H),5.54(d,1H),5.45(d,1H),5.22(d,1H),5.00(d ,1H),4.77-4.71(t,2H),4.19-4.12(t,2H),2.55(m,1H),2.06(s,3H),1.09(d,3H),1.00(d,3H). 13 CNMR (125MHz, CDCl 3 , ppm): δ=184.59, 174.07, 138.89, 136.79, 129.63, 127.50, 123.05, 101.93, 100.20, 88.20, 88.07, 82.63, 81.40, 71.19...

Embodiment 2

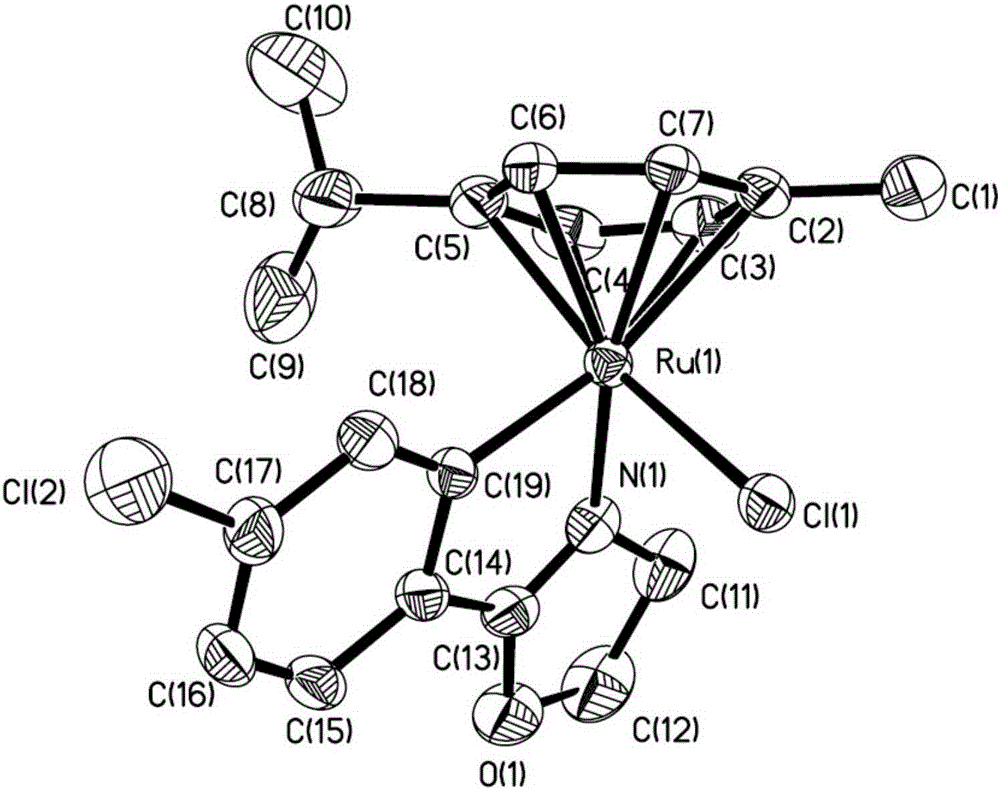

[0049] Put 1 mmol of dichloro(p-methylisopropylphenyl) ruthenium (II) dimer, 2.4 mmol of L2 and 4 mmol of potassium acetate into a 50 mL reaction tube, and take 25 mL of acetonitrile as a solvent. The above mixture was heated, stirred and refluxed for 20 hours, then cooled to room temperature. The solvent was then removed using a rotary evaporator, and the resulting solid was washed with diethyl ether. The product was recrystallized from ethyl acetate and dichloromethane and dried to give 869 mg of the green product 1b in 85% yield. The parameters of the proton nuclear magnetic spectrum and the carbon nuclear magnetic spectrum of the product made are: 1 HNMR (500MHz, CDCl 3 ,ppm): δ=8.26(s,1H),7.20(d,1H),7.12(d,1H),5.54(d,1H),5.46(d,1H),5.22(d,1H),4.50(d ,1H),4.77-4.69(t,2H),4.18-4.10(t,2H),2.55(m,1H),2.06(s,3H),1.09(d,3H),1.00(d,3H). 13 CNMR (500MHz, CDCl 3 , ppm): δ=185.15, 174.21, 141.62, 130.01, 127.79, 126.44, 125.85, 101.97, 100.25, 88.19, 88.08, 82.68, 81.34, 71.20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com