Pulsating heat pipe heat exchanger with ammonia water as media and stainless steel as materials

A technology of pulsating heat pipes and heat exchangers, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve problems that no one has raised, and achieve rapid startup, avoid chemical reactions, and avoid temperature-sudden startup The effect of features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

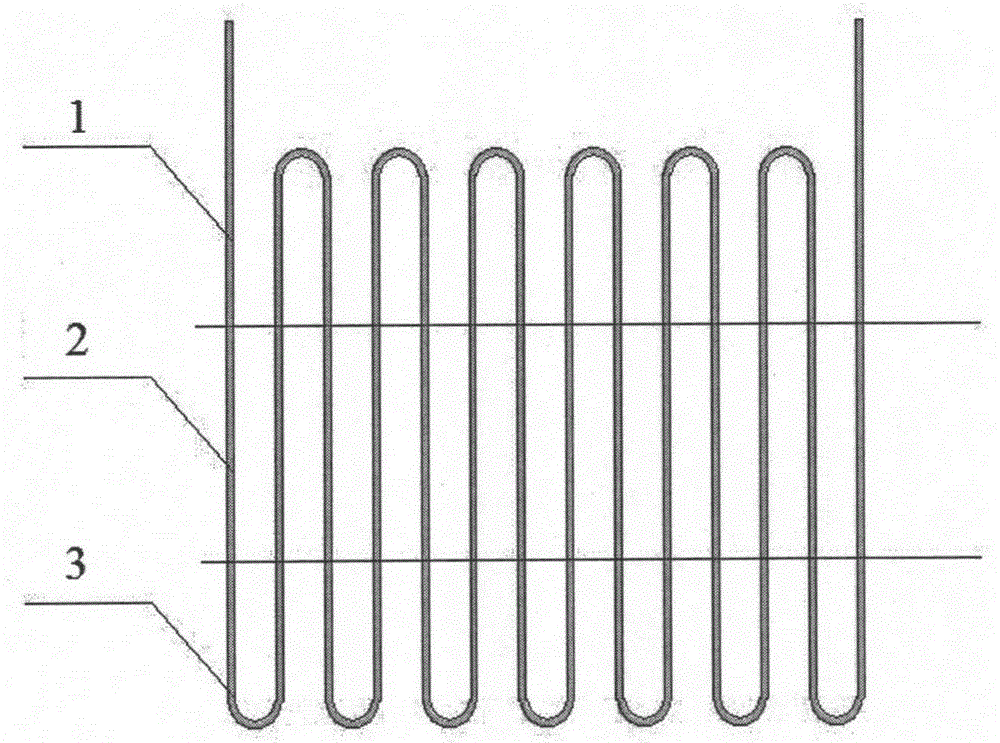

[0025] Such as figure 1 Shown is a schematic structural diagram of an open pulsating heat pipe heat exchanger. The pulsating heat pipe heat exchanger includes 6 circuits of pulsating heat pipes. The pulsating heat pipes are made of stainless steel, and the pulsating heat pipes are filled with ammonia solution as a working medium. The ammonia solution is formed by mixing liquid ammonia and water. The volume concentration of the ammonia solution is 25%-28%, and the filling rate is 55%.

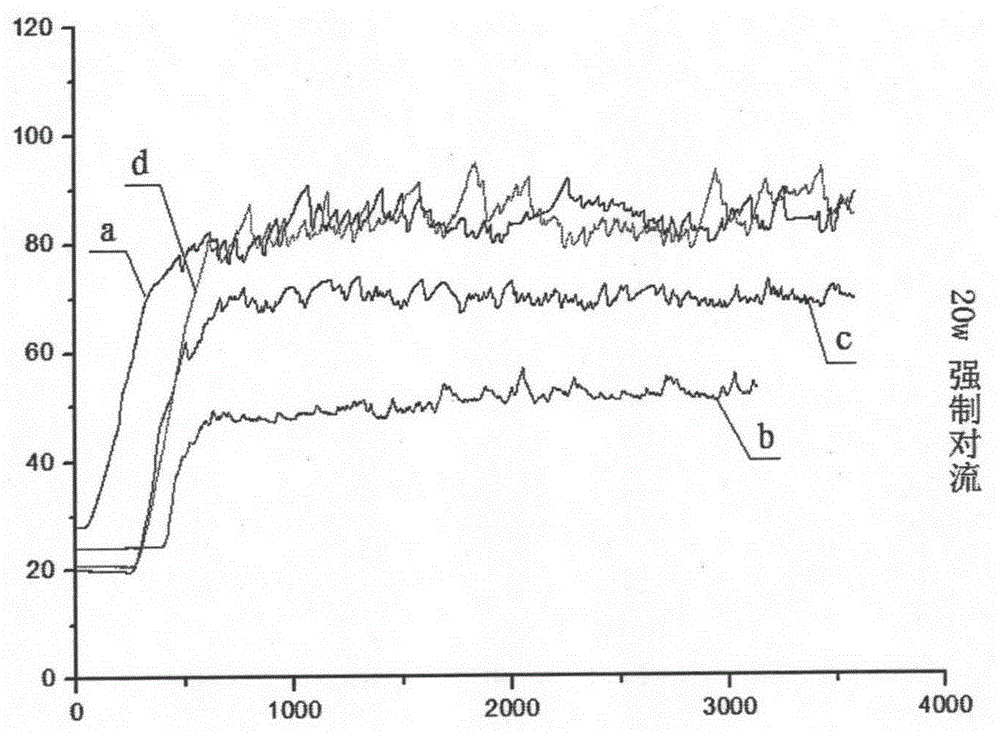

[0026] Measure the start-up characteristics of the above-mentioned pulsating heat pipe heat exchanger with ammonia water as the medium and stainless steel as the material, and compare it with the deionized water, absolute ethanol, and alcohol solution with a concentration of 25%-28% as the medium and stainless steel as the material. The start-up characteristics of the pulsating heat pipe heat exchanger are used for comparison. The specific measurement steps are as follows:

[0027] (1) The el...

Embodiment 2

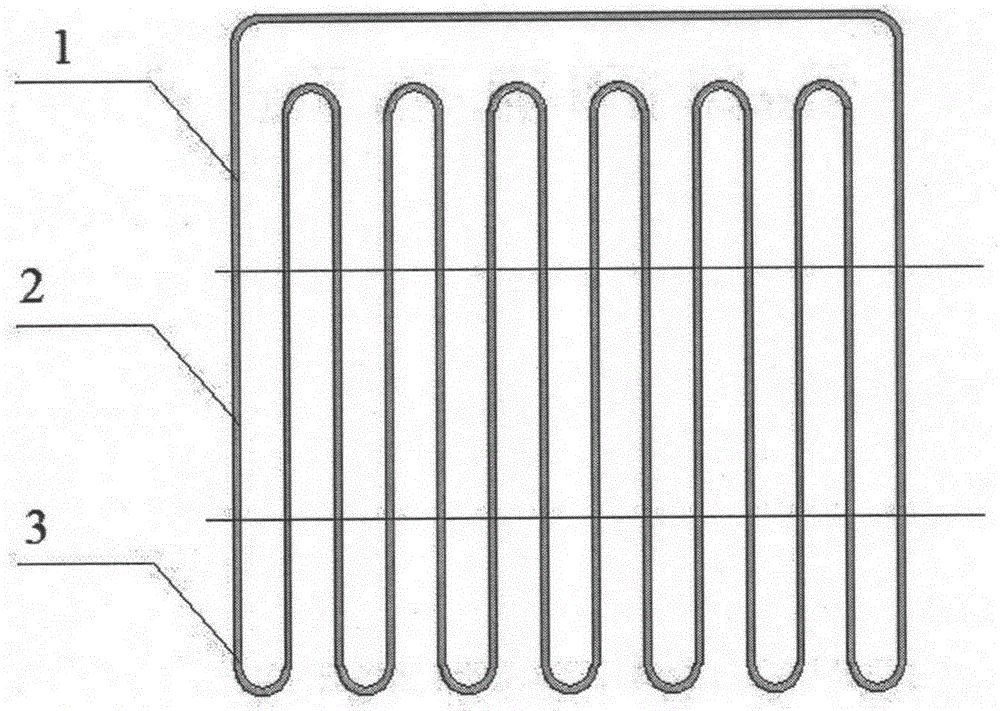

[0039] Such as figure 2 Shown is a schematic structural diagram of a closed pulsating heat pipe heat exchanger. The pulsating heat pipe heat exchanger described above is similar to Embodiment 1, except that the two pulsating heat pipes at the head and tail are connected to each other to form a closed loop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com