Automatic pig breeding farm waste treatment system and method

A treatment system and manure technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of large-scale pig farm manure treatment, large price fluctuations, waste of water resources, etc., to reduce the burden of sewage treatment , Realize the effect of automatic control and reduce the use of chemical fertilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

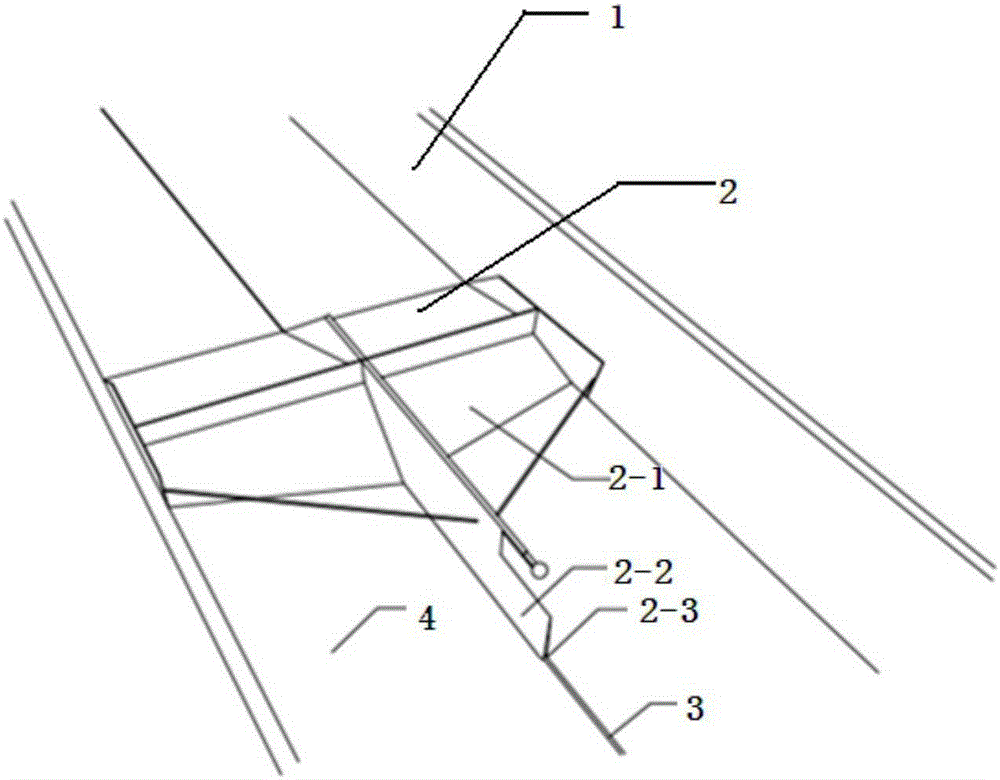

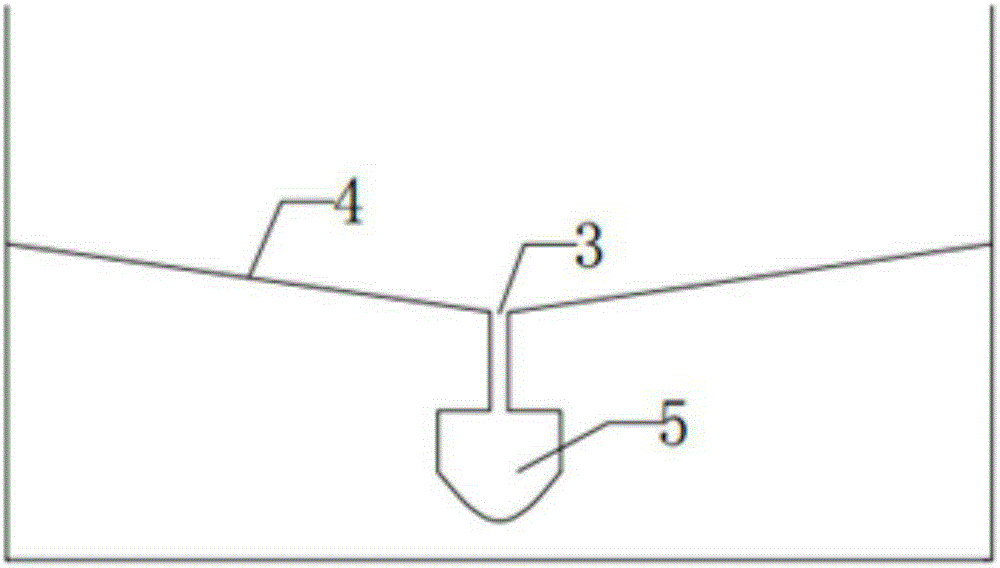

[0033] An automatic manure treatment system for pig farms, including mechanical excrement scraping equipment for separation of feces and urine in the pig house, automatic feces transportation equipment outside the house, feces fermentation equipment, organic fertilizer production equipment and sewage purification treatment equipment; wherein, the pig house Internal feces and urine separation machinery scraping equipment ( figure 2 with 3 ) includes a slatted floor located in the pig house, a manure scraping channel 1, a mechanical manure scraping plate 2 and a sewage pipe 5, the manure scraping channel 1 is located under the slatted floor, and the bottom 4 of the manure scraping channel is high at both ends and low in the middle There is a gap 3 at the lowest point in the middle, and the bottom of the gap 3 is the sewage pipe 5, and the urine enters the sewage pipe 5 through the gap 3; the mechanical scraper 2 in the mechanical scraper equipment for excrement and urine separa...

Embodiment 2

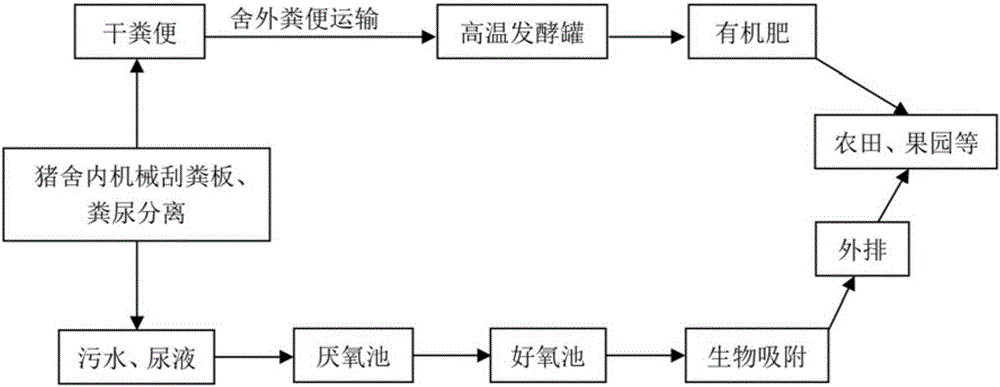

[0038] A method utilizing the system described in the embodiment to automatically process pig farm manure ( figure 1 ): pig feces, urine and sewage from cleaning the pig house enter the pig house through the slatted floor in the pig house to the scraping channel 1 of the feces and urine separation machinery scraping equipment, and the urine and sewage enter the sewage pipe 5 through the gap 3, The sewage pipeline 5 is connected with the sewage ditch 9 in the automatic excrement transportation equipment outside the house, and the sewage ditch 9 communicates with the sewage treatment tank through the sewage channel, and the sewage including urine enters the sewage treatment of the sewage purification treatment equipment through the sewage channel The mechanical dung scraper 2 and the electric transport dung truck 6 are uniformly controlled by the computer, and the feces are scraped into the electric transport dung truck 6 of the automatic excrement transport equipment outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com