Engine oil seal assembly and detection automatic complete equipment based on visual technology

A vision technology and engine technology, applied in manipulators, measuring devices, and optical devices, etc., can solve problems such as increasing the cost of use, affecting the appearance of products, and inability to guarantee the direction of force, so as to improve stability and reliability, and improve prototype performance. , the effect of reducing interface failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings of the embodiments.

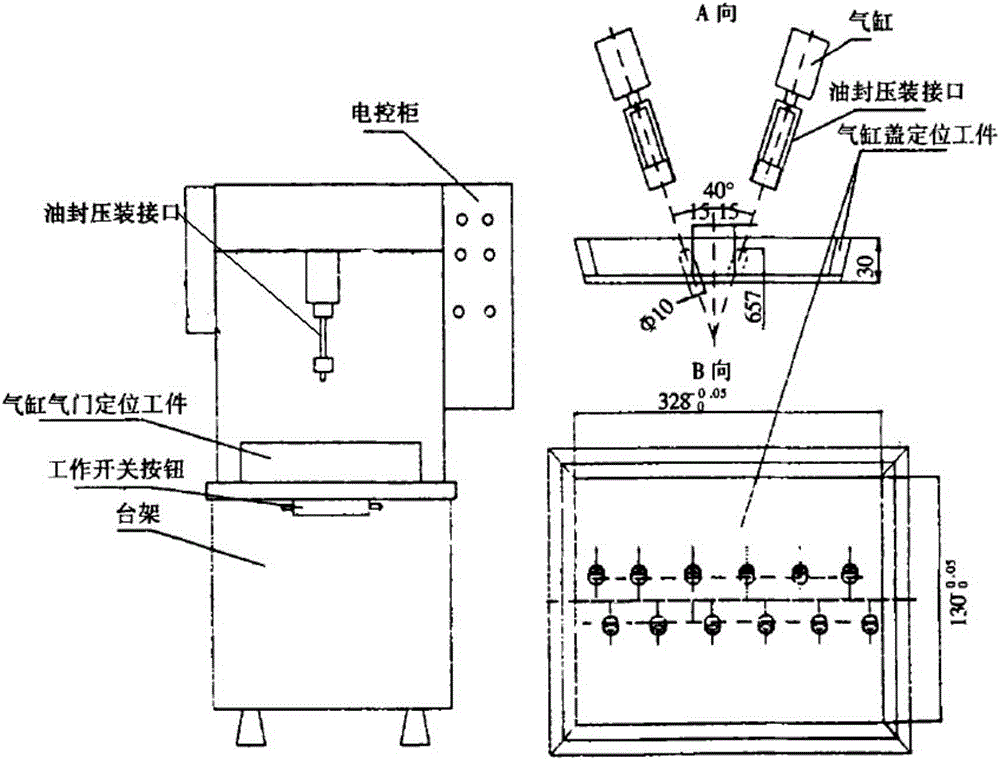

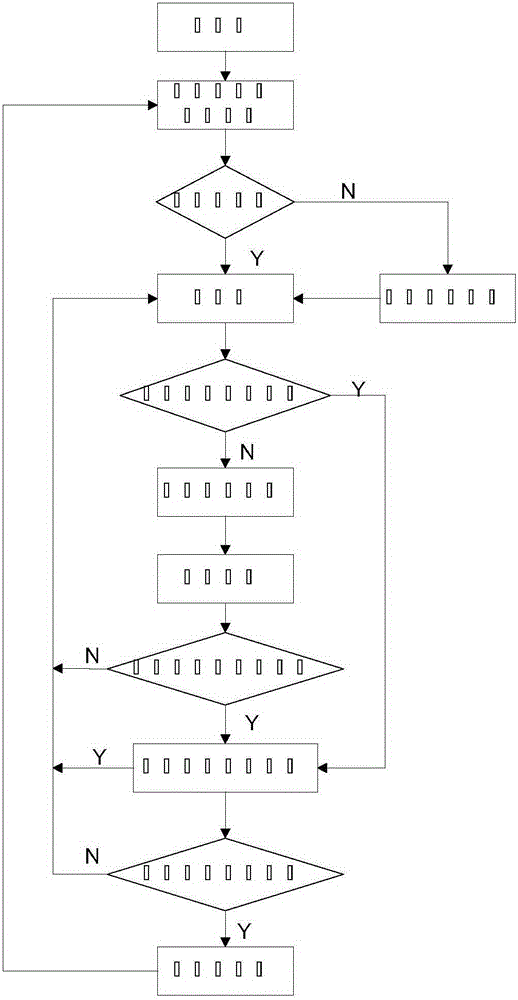

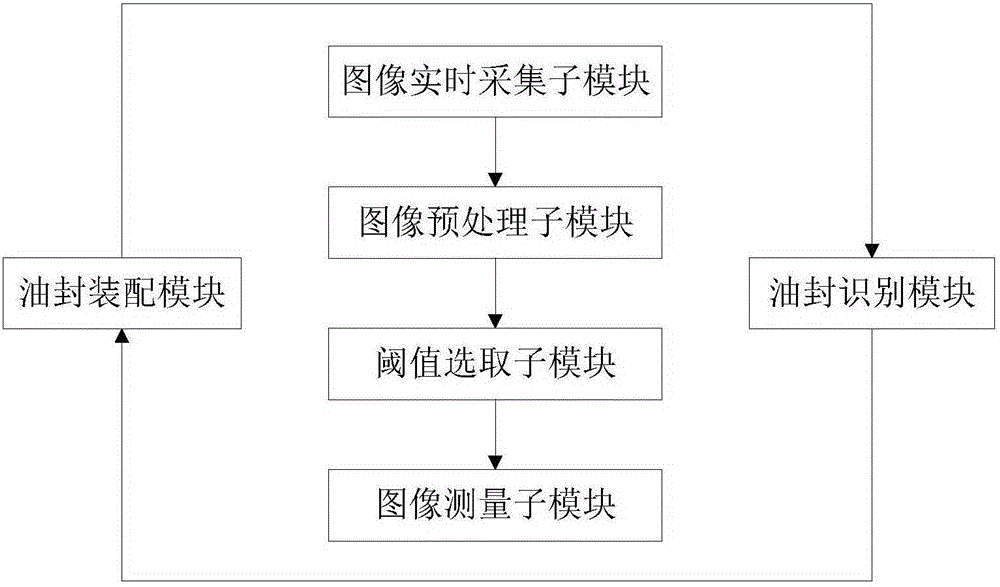

[0030] 1) The overall scheme of engine oil seal assembly and inspection automation complete equipment based on vision technology. The actions in the oil seal automatic assembly and inspection process are as follows in sequence: 6-axis manipulator moves to the pick-up point—turns on the vacuum pump—absorbs the oil seal—moves Arrive at the distribution point of the oil seal—correct the coordinate value, lower the manipulator and open the air valve—turn off the vacuum (blowing air)—assemble the oil seal—throw away the unqualified oil seal—move to the pick-up point to start the next cycle, The whole process is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com