Automatic moxa cone winding device

A linkage device and automatic technology, applied in the direction of packaging automatic control, packaging, packaging protection, etc., can solve the problems of long interval of forming moxa, low hand-made kneading rate and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

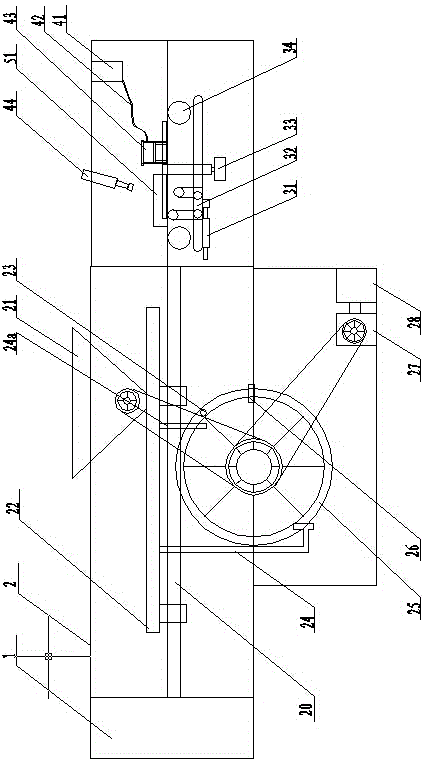

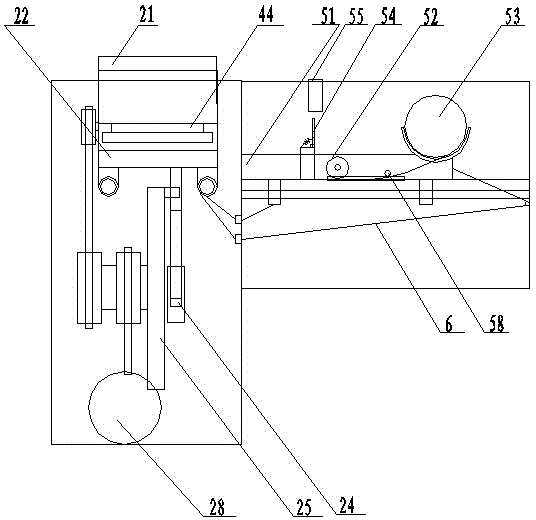

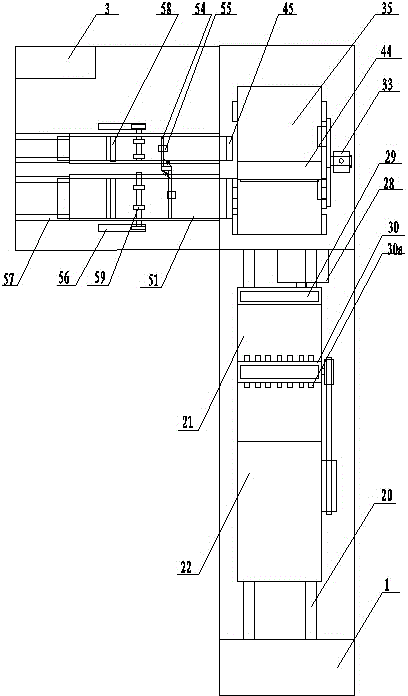

[0036] Embodiment one, such as Figure 1-5 Shown: a kind of moxa column automatic rolling device, including frame 2 and the paper feeding mechanism interconnected with the control mechanism signal arranged on the frame 2, the feeding mechanism that doubles as feeding, the winding mechanism and the control mechanism, the described feeding mechanism The winding mechanism is fixedly placed at the front end of the mechanism, and the paper feeding mechanism is arranged on the left side of the winding mechanism, and the feeding mechanism and the paper feeding mechanism are movably connected through the linkage device 6 of double pull ropes.

[0037] Described paper feed mechanism comprises the paper feed chute 51 that can move on frame 2, and the paper feed chute 51 that adopts is arranged on the slide rail 57, and the slide rail 57 that adopts is cylindrical, and the afterbody of paper feed chute 51 is provided with packaging The paper bin 53 is fixedly provided with a leveling col...

Embodiment 2

[0042] Embodiment two, such as Figure 1-5 Shown: a kind of moxa column automatic rolling device, including frame 2 and the paper feeding mechanism interconnected with the control mechanism signal arranged on the frame 2, the feeding mechanism that doubles as feeding, the winding mechanism and the control mechanism, the described feeding mechanism The winding mechanism is fixedly placed at the front end of the mechanism, and the paper feeding mechanism is arranged on the left side of the winding mechanism, and the feeding mechanism and the paper feeding mechanism are movably connected through the linkage device 6 of the double cylinder.

[0043] Described paper feed mechanism comprises the paper feed chute 51 that can move on frame 2, and the paper feed chute 51 that adopts is arranged on the slide rail 57, and the slide rail 57 that adopts is cylindrical, and the afterbody of paper feed chute 51 is provided with packaging The paper bin 53 is fixedly provided with a leveling c...

Embodiment 3

[0047] Embodiment three, such as Figure 1-5 Shown: a kind of moxa column automatic rolling device, including frame 2 and the paper feeding mechanism interconnected with the control mechanism signal arranged on the frame 2, the feeding mechanism that doubles as feeding, the winding mechanism and the control mechanism, the described feeding mechanism A rewinding mechanism fixedly placed at the front end of the mechanism, a paper feeding mechanism is arranged on the left side of the rewinding mechanism, and the feeding mechanism and the paper feeding mechanism are movably connected through the linkage device 6 of two lead screws.

[0048] Described paper feed mechanism comprises the paper feed slot 51 that can move on frame 2, and the paper feed slot 51 that adopts is arranged on the slide rail 57, and the slide rail 57 that adopts is cylindrical, and the machine at the afterbody of paper feed slot 51 Frame 2 is provided with wrapping paper storehouse 53, and the leveling post 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com