Water treatment agent and preparing method thereof

A water treatment agent, the technology of mass parts, applied in the field of water treatment agent and its preparation, can solve the problems of limited water purification effect, increase the difficulty of water purification, multiple preparations, etc., achieve a wide range of PH use, good adsorption, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

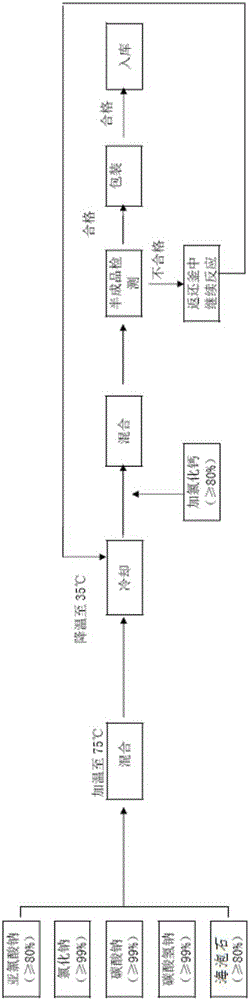

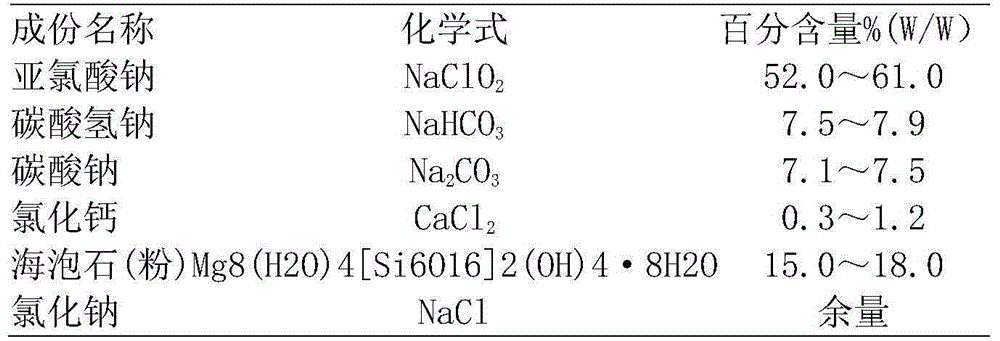

[0022] Below in conjunction with specific embodiment and attached figure 1 The present invention is further described. Example 1, the formula is:

[0023]

[0024] The preparation method comprises the following steps:

[0025] 1) Weigh the powdery raw materials sodium chlorite, sodium bicarbonate, sodium carbonate, sodium chloride and sepiolite and put them into the reaction kettle; heat up to 75°C while stirring, and the heating rate is 12°C / min, and then Mix for 35 minutes;

[0026] 2) After cooling down to 35°C, add powdered calcium chloride and mix for 28 minutes;

[0027] 3) Packaging.

example 2

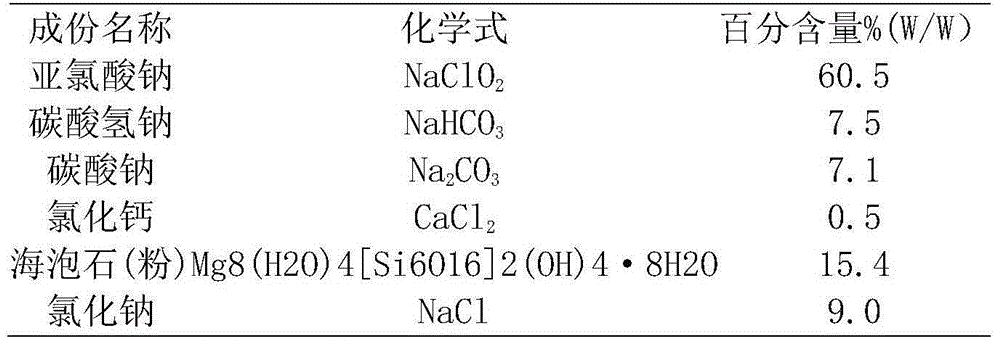

[0028] Example 2 (better solution), the formula is:

[0029]

[0030] The preparation method comprises the following steps:

[0031] 1) Weigh the powdery raw materials sodium chlorite, sodium bicarbonate, sodium carbonate, sodium chloride and sepiolite and put them into the reaction kettle; heat up to 75°C while stirring, and the heating rate is 12°C / min, and then Mix for 28 minutes;

[0032] 2) After cooling down to 35°C, add powdered calcium chloride and mix for 35 minutes;

[0033] 3) Packaging.

example 3

[0034] Example 3, the formula is:

[0035]

[0036] The preparation method comprises the following steps:

[0037] 1) Weigh the powdery raw materials sodium chlorite, sodium bicarbonate, sodium carbonate, sodium chloride and sepiolite and put them into the reaction kettle; heat up to 75°C while stirring, and the heating rate is 12°C / min, and then Mix for 30 minutes;

[0038] 2) After cooling down to 35°C, add powdered calcium chloride and mix for 30 minutes;

[0039] 3) Packaging.

[0040] Use examples 1-3 water treatment agent dissolved in the same batch of outdoor landscape water (5g / L) after collecting water, let it stand for 10 minutes, filter out the sediment and then test, some of the results are as follows:

[0041] Total coliforms: not detected; (13000CFU / mL before use).

[0042] Heat-resistant coliform group: not detected (6000CFU / mL before use).

[0043] Escherichia coli: not detected (2000CFU / mL before use).

[0044] The total number of colonies (CFU / mL): E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com