AAO-MBR sewage processing device and optimization operation method

A sewage treatment equipment, sewage technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as differences in sludge settling performance, reduce operating energy consumption and The effect of project investment, energy saving and improving effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

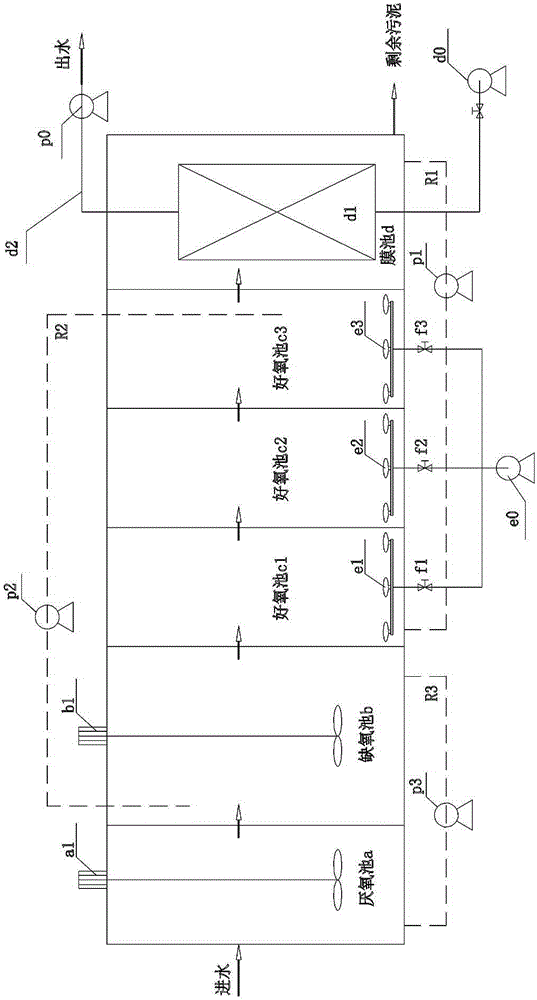

[0030] Embodiment one, refer to figure 1 and figure 2 , a kind of AAO-MBR sewage treatment equipment, including interconnected anaerobic pool a, anoxic pool b, aerobic pool c and membrane pool d.

[0031] The agitator a1 and b1 are respectively arranged in the anaerobic pool a and the anoxic pool b; the membrane module d1 is arranged in the membrane pool d, the membrane module d1 adopts a hollow fiber membrane, the anaerobic pool a has a water inlet, and the membrane pool d With excess sludge outlet, membrane module d1 is connected to blower d0 and outlet pipe d2.

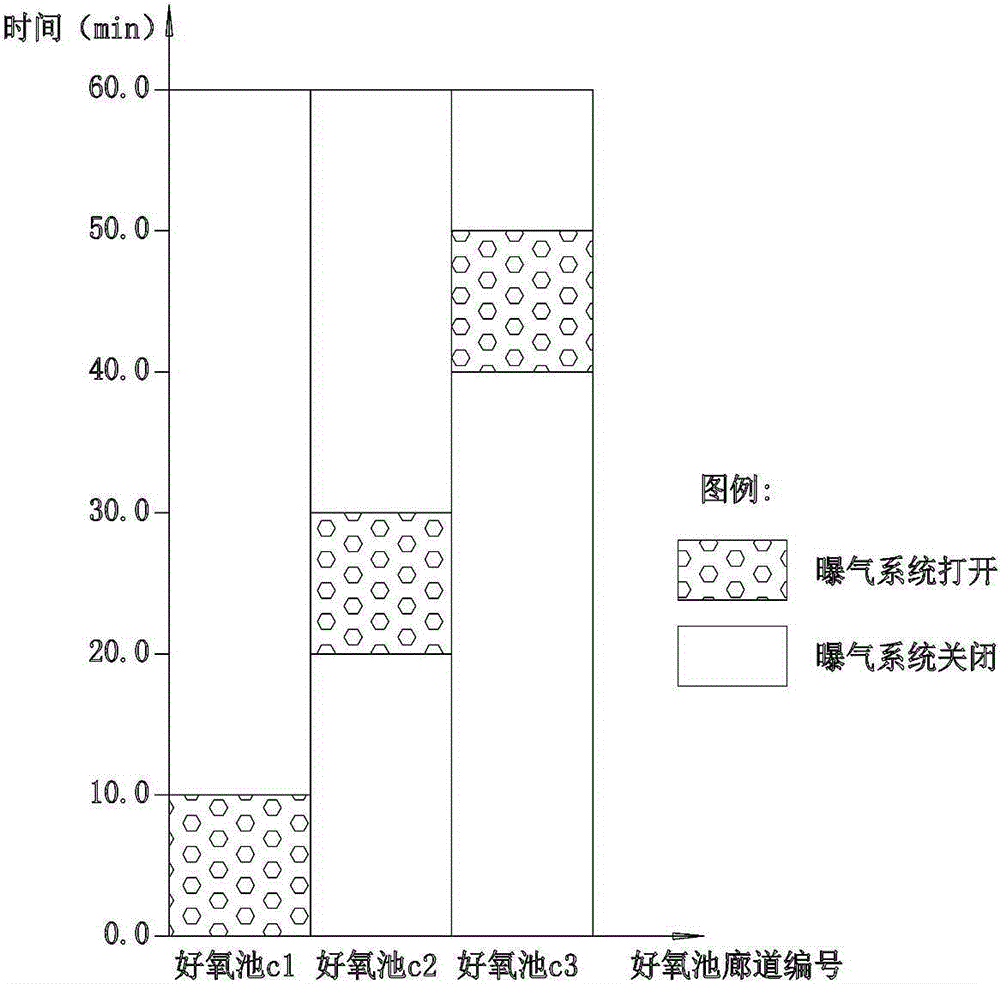

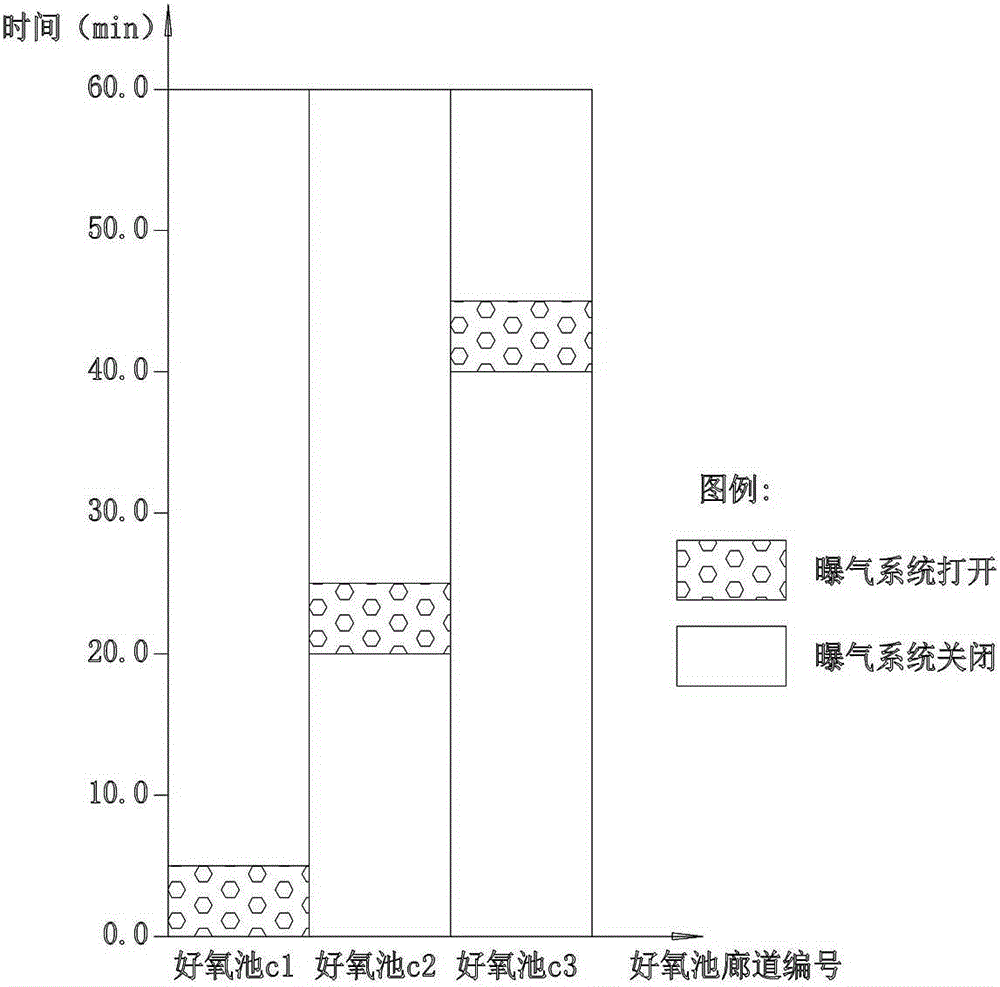

[0032] The aerobic pool c is composed of three corridors in series, which are the aerobic pool c1, the aerobic pool c2, and the aerobic pool c3. The first aeration system e1, the second aeration system e2, and the third aeration system e3 are connected to the blower e0 through pipes and valves f1, f2, and f3, respectively.

[0033] This treatment equipment contains three sets of internal circulation systems: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com