Deep treatment method for industrial glucose wastewater

A technology for industrial wastewater and advanced treatment, applied in the field of glucose industrial production, can solve problems such as substandard wastewater treatment, and achieve the effects of increasing operating costs, increasing specific surface area, and increasing treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the present invention will be described in detail through specific embodiments.

[0023] A method for advanced treatment of glucose industrial wastewater, including the following steps:

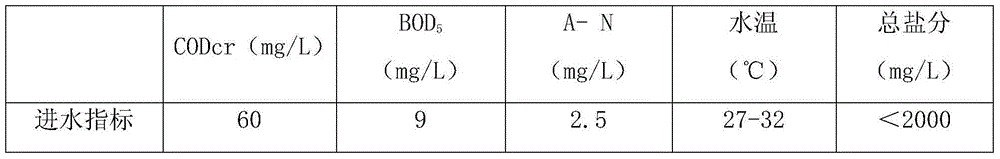

[0024] (1) Conventional treatment: pass the glucose industrial wastewater through an EGSB reactor; A / O aerobic and sedimentation treatment to obtain external drainage; after conventional processing, the biodegradability is poor, and BOD5 / CODcr≤0.2 is difficult to degrade Range, where CODcr is about 60mg / L;

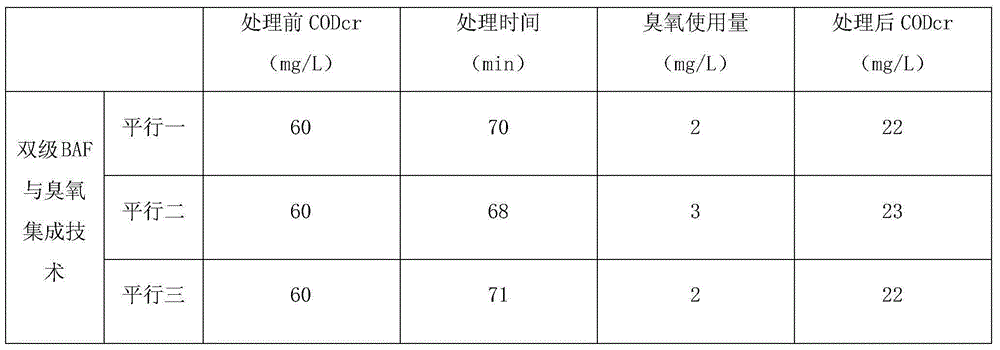

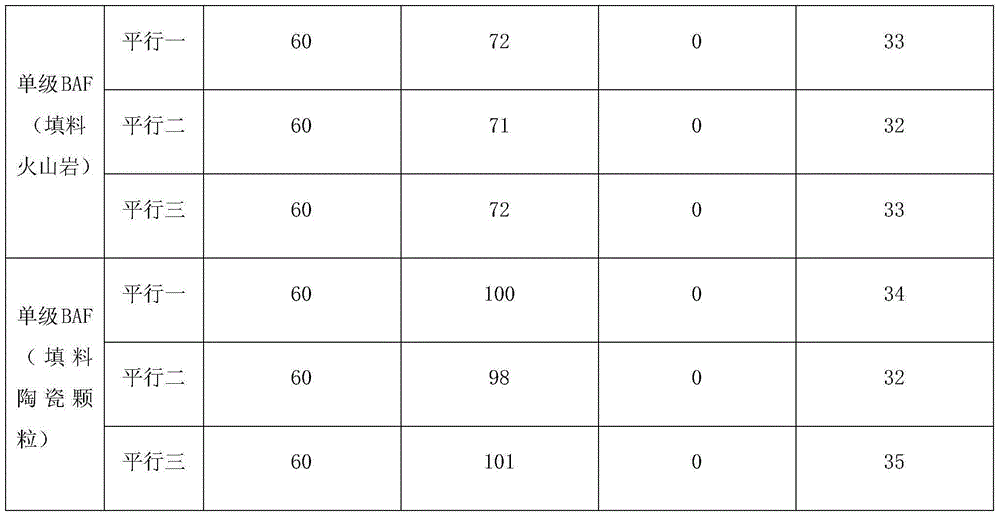

[0025] (2) Primary aeration: the external drainage that has undergone the conventional treatment in step (1) is pumped into the primary aeration biological filter through a water pump, and the water is discharged after one aeration treatment; the first aeration time is 30 minutes, Dissolved oxygen is controlled at 10mg / L. The microbial carrier of the primary biological aerated filter is volcanic rock. Using volcanic rock as the microbial carrier of the primary aerated biol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com