Treatment method for dyeing and printing effluent

A printing and dyeing sewage and treatment method technology, applied in the field of sewage treatment and printing and dyeing sewage treatment, can solve the problems of increased difficulty in treatment and reduced biodegradability of organic pollutants, so as to improve biodegradability, save energy and run The effect of low cost and low sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

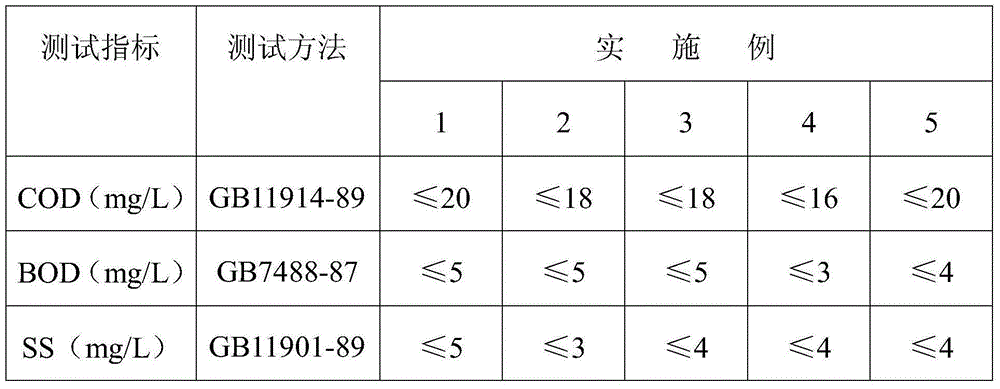

Examples

Embodiment 1

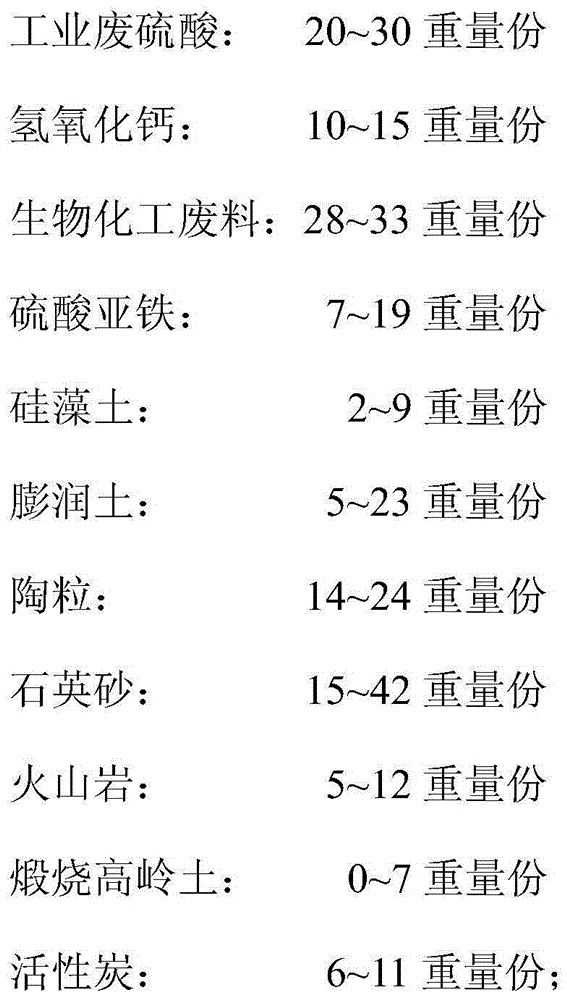

[0057] (1) Primary sedimentation step: the printing and dyeing sewage flows to the primary sedimentation tank and stays for 3.5h to remove impurities, sinkables and floating objects; the primary sedimentation tank contains 20 parts by weight of industrial waste sulfuric acid, 10 parts by weight of calcium hydroxide, 33 parts by weight of biochemical waste, 19 parts by weight of ferrous sulfate, 2 parts by weight of diatomite, 5 parts by weight of bentonite, 14 parts by weight of ceramsite, 15 parts by weight of quartz sand, 12 parts by weight of volcanic rock, 7 parts by weight of calcined kaolin and 6 parts by weight Parts by weight activated carbon;

[0058] (2) Filtration: pump the supernatant obtained in step (1) to filter to remove suspended particles in the water;

[0059] (3) Hydrolysis and acidification treatment: pump the sewage filtered in step (2) into the hydrolysis and acidification tank to stay for 5 hours, and carry out hydrolysis and acidification treatment;

...

Embodiment 2

[0067] (1) Primary sedimentation step: the printing and dyeing sewage flows to the primary sedimentation tank and stays for 1 hour to remove impurities, sinkables and floating objects; the primary sedimentation tank contains 30 parts by weight of industrial waste sulfuric acid, 15 parts by weight of calcium hydroxide, 28 Parts by weight of biochemical waste, 7 parts by weight of ferrous sulfate, 9 parts by weight of diatomite, 23 parts by weight of bentonite, 24 parts by weight of ceramsite, 42 parts by weight of quartz sand, 5 parts by weight of volcanic rock and 11 parts by weight of activated carbon;

[0068] (2) Filtration: pump the supernatant obtained in step (1) to filter to remove suspended particles in the water;

[0069] (3) Hydrolysis and acidification treatment: pump the sewage filtered in step (2) into the hydrolysis and acidification tank to stay for 10 hours, and carry out hydrolysis and acidification treatment;

[0070] (4) Anaerobic treatment: discharge the se...

Embodiment 3

[0077] (1) Primary sedimentation step: the printing and dyeing sewage flows to the primary sedimentation tank and stays for 2 hours to remove impurities, sinkables and floating objects; the primary sedimentation tank contains 25 parts by weight of industrial waste sulfuric acid, 12.5 parts by weight of calcium hydroxide, 30.5 parts by weight Parts by weight of biochemical waste, 13 parts by weight of ferrous sulfate, 5.5 parts by weight of diatomite, 14 parts by weight of bentonite, 19 parts by weight of ceramsite, 28.5 parts by weight of quartz sand, 8.5 parts by weight of volcanic rock, 3.5 parts by weight of calcined kaolin and 8.5 parts by weight activated carbon;

[0078] (2) Filtration: pump the supernatant obtained in step (1) to filter to remove suspended particles in the water;

[0079] (3) Hydrolysis and acidification treatment: pump the sewage filtered in step (2) into the hydrolysis and acidification tank to stay for 7.5 hours, and carry out hydrolysis and acidific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com