Detection method of trace substance content using micro-nano structure oxide ceramic material

A technology of trace substance content and oxide ceramics, applied in the field of spectroscopic analysis, can solve the problems of high production cost, poor SERS substrate sensitivity, poor repeatability, etc., and achieve the effects of low cost, environmental friendly cost and short preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

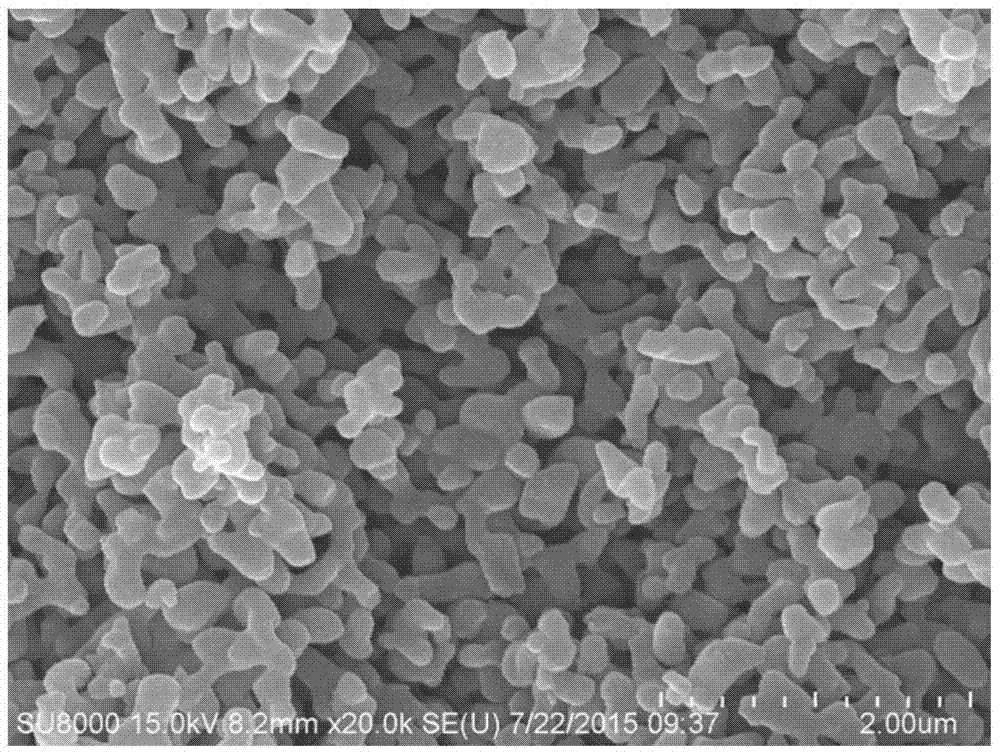

[0030] Specific implementation mode 1: This implementation mode is a preparation method of a micro-nano structure oxide ceramic material, which is specifically completed according to the following steps:

[0031] 1. Press green body: Put the oxide powder into the mold of the tablet press and put it into the tablet press, pressurize at a pressure boosting speed of 0.01MPa / s-10MPa / s to a pressure of 0.1MPa-40MPa, and pressurize Hold at 0.1MPa~40MPa for 10s~60s, and take out the obtained ceramic material green body;

[0032] 2. Roasting: put the ceramic material green body obtained in step 1 into a crucible and put it into a high-temperature furnace, set the temperature change program of the high-temperature furnace, so that the ceramic material green body is roasted at a temperature of 600°C to 1300°C for 0.5h to 4h, Take it out with the furnace cooling to room temperature, and obtain the micro-nano structure oxide ceramic material.

[0033] Oxides are widely used in the prepar...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the average particle size of the oxide powder in step 1 is 1 nm˜10 μm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the discreteness of the particle size distribution of the oxide powder described in step one90 -D 10 ) / D 50 , where D 90 Indicates that the particle size of the oxide powder is smaller than D 90 The mass fraction of oxide powder is 90%, D 10 Indicates that the particle size of the oxide powder is smaller than D 10 The mass fraction of oxide powder is 10%, D 50 Indicates that the particle size of the oxide powder is smaller than D 50 The mass fraction of oxide powder is 50%. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com