Preparation method of nicuzn ferrite material

A ferrite material and powder technology, applied in the field of NiCuZn ferrite material and preparation, can solve the problems of porous structure, low density and high ferromagnetic resonance line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

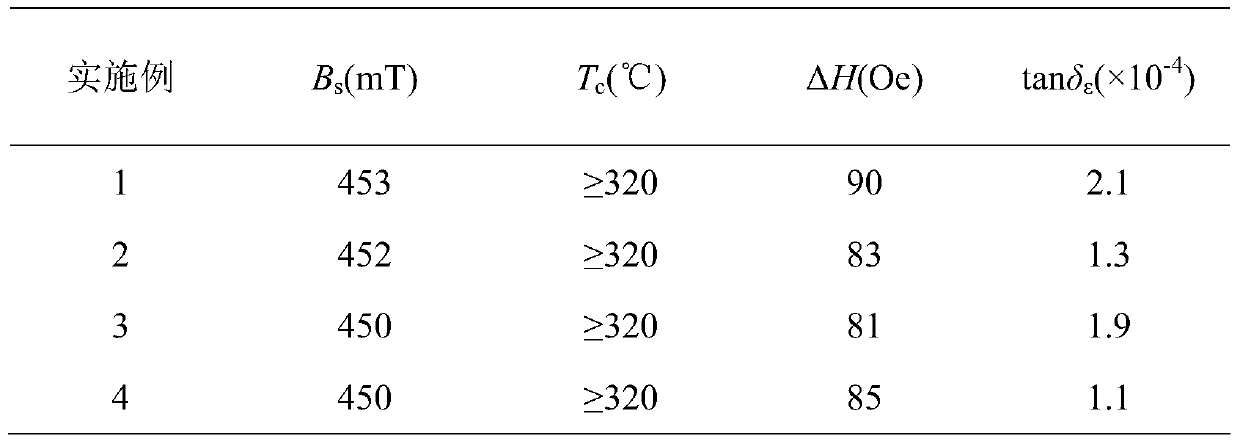

Examples

Embodiment 1

[0031] Embodiment 1: a kind of NiCuZn ferrite material and preparation method thereof, comprises the following steps:

[0032] 1) Recipe

[0033] Using Ni 0.37 co 0.15 Cu 0.1 Zn 0.4 Fe 1.98 o 3.99 ;

[0034] 2) Ball milling once

[0035] Mix the powder of the above formula evenly in a ball mill for 2 hours, and the ball milling medium is steel balls;

[0036] 3) pre-burning

[0037] Dry the ball mill material obtained in step 2), and pre-fire it in a furnace at 900°C for 2.5 hours;

[0038] 4) Doping

[0039] Step 3) the powder obtained by adding the following dopant by weight: 0.10wt% BaTiO 3 , 0.12wt% CaCO 3 , 0.08wt%V 2 o 5 , 0.12wt% Bi 2 o 3 ;

[0040] 5) Second ball milling

[0041] The powder obtained in step 4) is ball milled in a ball mill for 6 hours, the ball milling medium is zirconium balls, and the final powder particle size is 0.6-1.0 μm;

[0042] 6) Molding

[0043] Add 15wt% organic binder to the powder obtained in step 5) by weight, mix eve...

Embodiment 2

[0046] Embodiment 2: a kind of NiCuZn ferrite material and preparation method thereof, comprises the following steps:

[0047] 1) Recipe

[0048] Using Ni 0.37 co 0.15 Cu 0.1 Zn 0.4 Fe 1.98 o 3.99 ;

[0049] 2) Ball milling once

[0050] Mix the powder of the above formula evenly in a ball mill for 2 hours, and the ball milling medium is steel balls;

[0051] 3) pre-burning

[0052] Dry the ball mill material obtained in step 2), and pre-fire it in a furnace at 900°C for 2.5 hours;

[0053] 4) Doping

[0054] Step 3) the powder obtained by adding the following dopant by weight: 0.20wt% BaTiO 3 , 0.06wt% CaCO 3 , 0.12wt% Bi 2 o 3 ;

[0055] 5) Second ball milling

[0056] The powder obtained in step 4) is ball milled in a ball mill for 6 hours, the ball milling medium is zirconium balls, and the final powder particle size is 0.6-1.0 μm;

[0057] 6) Molding

[0058] Add 15wt% organic binder to the powder obtained in step 5) by weight, mix evenly, and after gran...

Embodiment 3

[0061] Embodiment 3: a kind of NiCuZn ferrite material and preparation method thereof, comprises the following steps:

[0062] 1) Recipe

[0063] Using Ni 0.32 co 0.2 Cu 0.1 Zn 0.4 Fe 1.98 o 3.99 ;

[0064] 2) Ball milling once

[0065] Mix the powder of the above formula evenly in a ball mill for 2 hours, and the ball milling medium is steel balls;

[0066] 3) pre-burning

[0067] Dry the ball mill material obtained in step 2), and pre-fire it in a furnace at 900°C for 2.5 hours;

[0068] 4) Doping

[0069] Step 3) the powder obtained by adding the following dopant by weight: 0.10wt% BaTiO 3 , 0.12wt% CaCO 3 , 0.08wt%V 2 o 5 , 0.12wt% Bi 2 o 3 ;

[0070] 5) Second ball milling

[0071] The powder obtained in step 4) is ball milled in a ball mill for 6 hours, the ball milling medium is zirconium balls, and the final powder particle size is 0.6-1.0 μm;

[0072] 6) Molding

[0073] Add 15wt% organic binder to the powder obtained in step 5) by weight, mix even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com