Static-pressure high-strength wear-resisting concrete anti-blocking and water-permeable brick and preparation method thereof

A technology of concrete and permeable bricks, applied in the field of building materials, can solve the problems of low compressive strength, poor water permeability, easy blockage, etc., achieve high comprehensive utilization index of resources, solve poor water permeability, and ensure the effect of water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

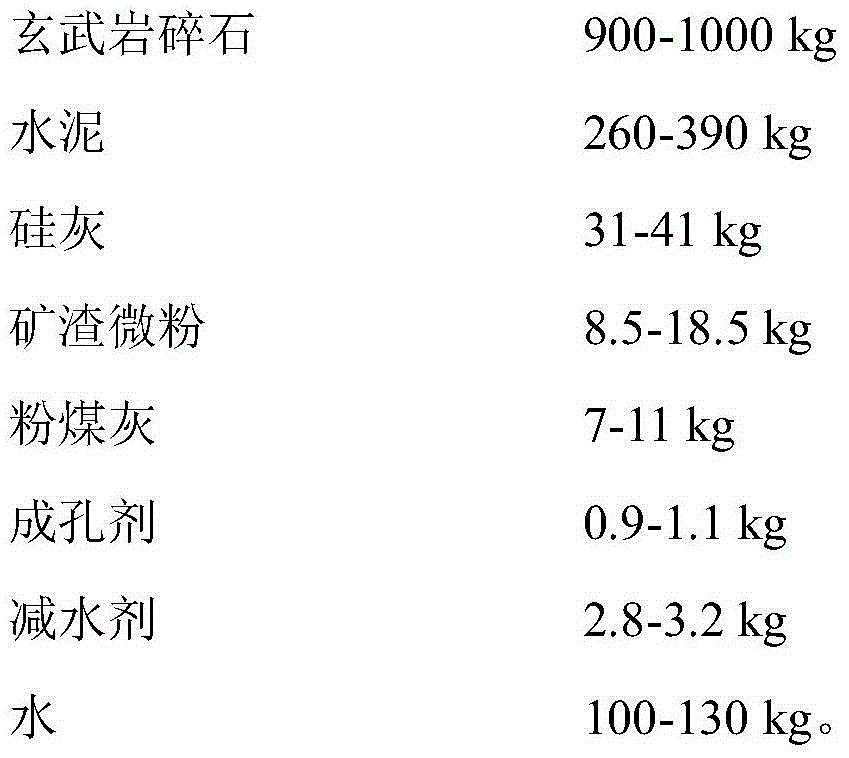

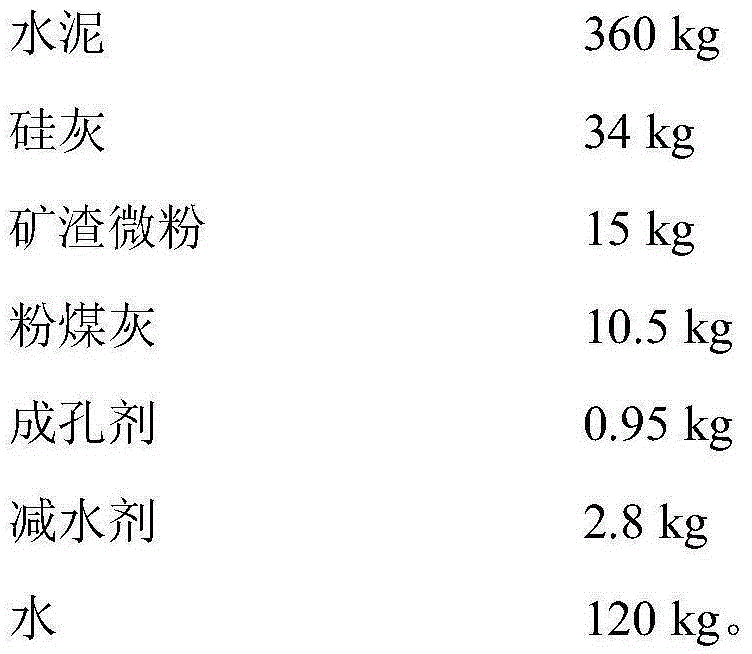

[0031] A static pressure high-strength wear-resistant concrete anti-blocking permeable brick of this embodiment, the proportion of each raw material per cubic meter is: 990kg of basalt gravel, 360kg of low-alkali cement, 34kg of silica fume, 15kg of slag powder, 10.5kg of first-grade Fly ash, 0.95kg pore forming agent, 2.8kg superplasticizer and 120kg clean tap water.

[0032] The permeable brick aggregate used in this example is basalt gravel with a particle size of 7-10mm produced by Ma'anshan Longma Stone Factory. The aggregate has high strength, uniform particle size and no impurities. The low-alkali cement is the model 42.5# low-alkali Portland cement produced by Tangshan Special Cement Factory. The water reducer is the JY-PCA polycarboxylate high-efficiency water reducer produced by Shanghai Lidian New Material Co., Ltd., the silica fume is 800 mesh silica fume produced by Suzhou Zunyue New Material Co., Ltd., and the pore-forming agent is Shanghai Lidian The phenolic r...

Embodiment 2

[0041] A static pressure high-strength wear-resistant concrete anti-blocking permeable brick of this embodiment is basically the same as that of Embodiment 1, except that the proportion of each raw material per cubic meter is: 1000 kg of basalt gravel, 390 kg of low-alkali cement, 36kg of silica fume, 13.5kg of slag powder, 9kg of first-class fly ash, 1.0kg of pore forming agent, 2.8kg of high-efficiency water reducer and 115kg of clean tap water.

[0042] Taking the preparation of anti-blocking permeable bricks with a volume of 1 cubic meter as an example, the process of preparing high-strength wear-resistant concrete anti-blocking permeable bricks in this example is as follows:

[0043] Take 1000kg of basalt gravel, 390kg of low-alkali cement, 36kg of 800-mesh silica fume, 13.5kg of slag powder, 9kg of fly ash and 115kg of water, put them into a gravity-free mixer, and stir them evenly for 5 minutes. Put 1.0kg of pore-forming agent and 2.8kg of water-reducing agent into the ...

Embodiment 3

[0046] A static pressure high-strength wear-resistant concrete anti-blocking permeable brick of this embodiment is basically the same as that of Embodiment 1, except that the proportion of each raw material per cubic meter is: 900 kg of basalt gravel, 260 kg of low-alkali cement, 31kg of silica fume, 8.5kg of slag powder, 7kg of first-class fly ash, 0.9kg of pore forming agent, 2.8kg of high-efficiency water reducer and 100kg of clean tap water.

[0047] Taking the preparation of anti-blocking permeable bricks with a volume of 1 cubic meter as an example, the process of preparing high-strength wear-resistant concrete anti-blocking permeable bricks in this example is as follows:

[0048] Take 900kg of basalt gravel, 260kg of low-alkali cement, 31kg of 800-mesh silica fume, 8.5kg of slag powder, 7kg of fly ash and 100kg of water, put them into a gravity-free mixer, and stir them evenly for 4 minutes. Put 0.9kg of pore-forming agent and 2.8kg of water-reducing agent into the obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com