Composite 3D printing material and preparation method thereof

A 3D printing and raw material technology, applied in the field of composite 3D printing material preparation, can solve problems such as insufficient strength, and achieve the effects of high flexural elastic modulus, wide source, good environmental and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

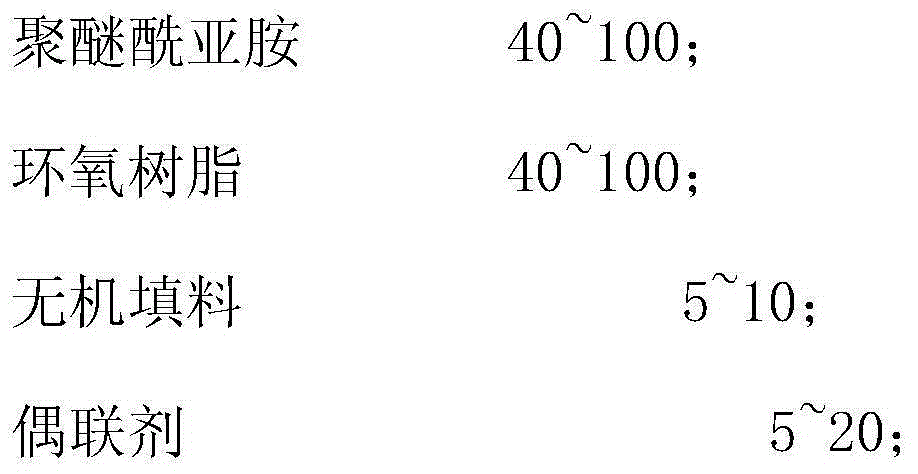

[0026] Prepare raw materials according to the raw materials of following weight parts:

[0027] Polyetherimide 40; glycidylamine epoxy resin 40; inorganic filler 10; zirconium coupling agent 5; 2-hydroxy-4-methoxybenzophenone 0.1; polydimethylsiloxane 0.1 ; 2,6-tertiary butyl-4-methylphenol 0.1; styrene-butadiene glue 0.1; polyethylene wax 1.

[0028] The inorganic filler is potassium titanate whisker with a diameter of 0.1-5 microns, a length of 5-100 microns, a density of 4 g / cm3 and a purity (wt%) of 90-99.9%.

[0029] The polyetherimide is a commercially available polyetherimide with an oxygen index of 47% and a density of 1.28-1.42 g / cm3.

[0030] The preparation process is:

[0031] 1) Put epoxy resin, antioxidant, dispersing lubricant, and coupling agent into the batching tank according to the stated formula, stir in a heating device at 600r / min for 1-3h, and heat at 100°C to obtain product A;

[0032] 2) adding inorganic fillers to the above-mentioned molten product...

Embodiment 2

[0036] Prepare raw materials according to the raw materials of following weight parts:

[0037] Polyetherimide 100; glycidylamine epoxy resin 100; inorganic filler 20; zirconium coupling agent 20; 2-hydroxy-4-methoxybenzophenone 0.5; polydimethylsiloxane 2 ; 2,6-tertiary butyl-4-methylphenol 2; styrene-butadiene glue 2; polyethylene wax 6.

[0038] The inorganic filler is potassium titanate whisker with a diameter of 0.1-5 microns, a length of 5-100 microns, a density of 4 g / cm3 and a purity (wt%) of 90-99.9%.

[0039] The polyetherimide is a commercially available polyetherimide with an oxygen index of 47% and a density of 1.28-1.42 g / cm3.

[0040] The preparation process is:

[0041] 1) Put epoxy resin, antioxidant, dispersing lubricant, and coupling agent into the batching tank according to the stated formula, stir in a heating device at 600r / min for 1-3h, and heat at 100°C to obtain product A;

[0042] 2) adding inorganic fillers to the above-mentioned molten product A,...

Embodiment 3

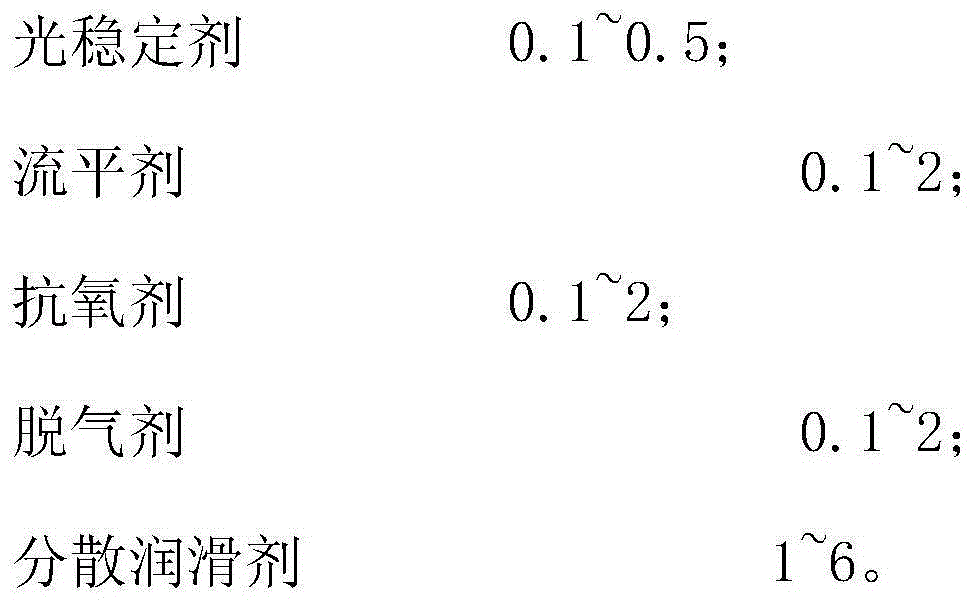

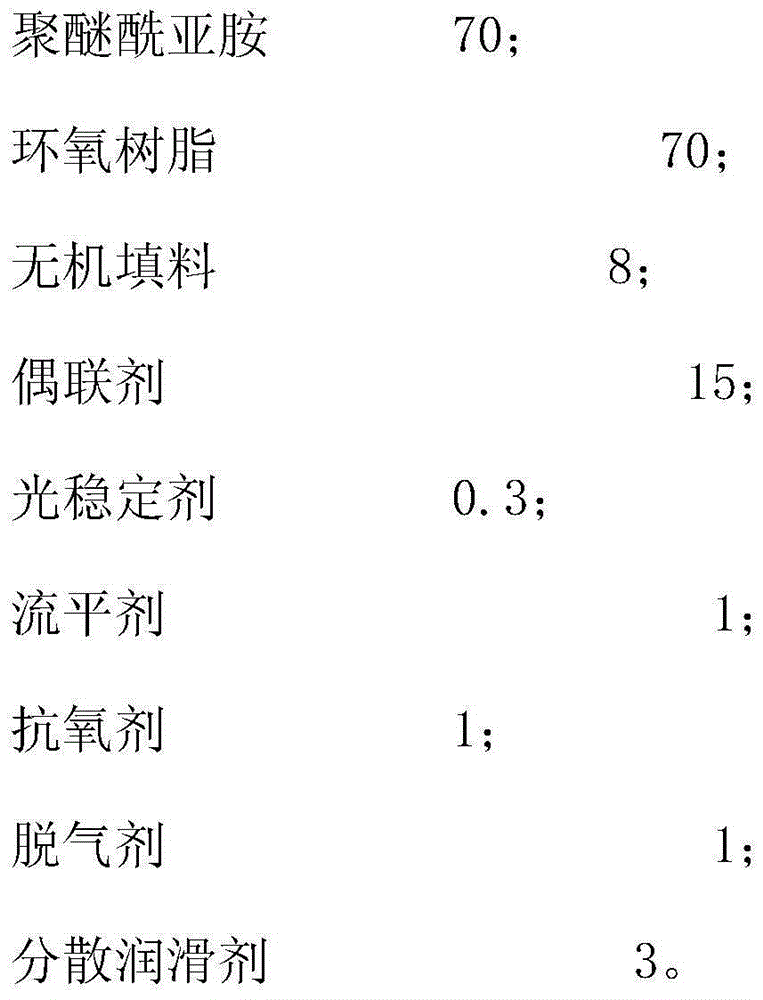

[0046] Prepare raw materials according to the raw materials of following weight parts:

[0047] Polyetherimide 40; glycidylamine epoxy resin 40; inorganic filler 10; zirconium coupling agent 5; 2-hydroxy-4-methoxybenzophenone 0.1; polydimethylsiloxane 0.1 ; 2,6-tertiary butyl-4-methylphenol 0.1; styrene-butadiene glue 0.1; polyethylene wax 1.

[0048] The inorganic filler is potassium titanate whisker with a diameter of 0.1-5 microns, a length of 5-100 microns, a density of 4 g / cm3 and a purity (wt%) of 90-99.9%.

[0049] The polyetherimide is a commercially available polyetherimide with an oxygen index of 47% and a density of 1.28-1.42 g / cm3.

[0050] The preparation process is:

[0051] 1) Put epoxy resin, antioxidant, dispersing lubricant, and coupling agent into the batching tank according to the stated formula, stir in a heating device at 600r / min for 1-3h, and heat at 100°C to obtain product A;

[0052] 2) adding inorganic fillers to the above-mentioned molten product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com