A kind of low-odor environment-friendly PVC powder coating composition and preparation method thereof

A powder coating and low-odor technology, applied in powder coatings, coatings, etc., can solve the problems of incomplete elimination of odor, different sizes, poor effects, etc., and achieves simple and easy preparation methods, high sanitation, Effect of improving low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

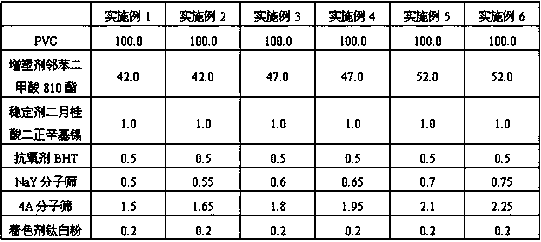

Examples

preparation example Construction

[0034] 2) Preparation of molecular sieves: Put NaY molecular sieves and 4A molecular sieves with a particle size of 4~5μm into a high-speed mixer in proportion to mix evenly, add polyethylene wax in proportion, and heat while mixing until the heating temperature reaches 100°C, and the molecular sieve powder begins to agglomerate Turn into small particles; stop heating and sieve the particles, and select particles with a particle size of 40-50 μm to obtain molecular sieves;

[0035] 3) Weigh the resin, plasticizer, heat stabilizer, antioxidant BHT, molecular sieve, colorant and other materials into the high and low speed mixer in proportion, stir and mix thoroughly, the stirring speed is 1000 rpm, the mixing time It takes 15 minutes. When the temperature of the mixed material reaches 120°C, it will be discharged into the low-speed mixer. When the temperature of the mixed material reaches 40~45°C, the material will be discharged into a low-odor and environmentally friendly PVC po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com