Metal cutting gas and preparation method thereof

A metal cutting and natural gas technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of insufficient combustion, insufficient cutting temperature of metal cutting gas, poor cutting quality, etc. Good cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A metal cutting gas, including natural gas and additives, the amount of additives added to natural gas is 3~5g / m 3 The additive is made of the following raw materials in parts by weight: p-xylene 50-60, ethylbenzene 20-30, m-xylene 10-15 and ferrocene 1-2.

[0018] The preparation method of the metal cutting gas, the specific preparation steps are as follows:

[0019] Step 1, preparation of additives: a. first measure p-xylene, ethylbenzene and m-xylene and mix them uniformly to obtain mixed solution a; b. measure 5-10% mixed solution a, and then add the formula amount of ferrocene to 5~10% mixture a is stirred evenly to obtain mixture b; c. add mixture b to the remaining mixture a and mix well;

[0020] Step 2: Put the additives into the liquefied natural gas in the tank according to the ratio, and the two are mutually dissolved and left for 10 hours to obtain the liquid-phase natural gas metal cutting gas;

[0021] Step 3: Transform the produced liquid-phase natural...

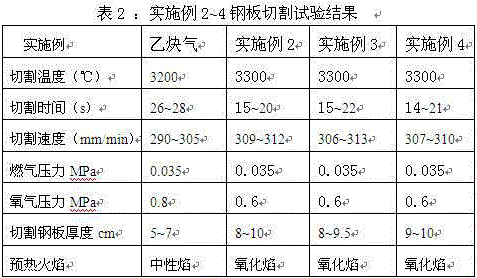

Embodiment 2

[0023] A metal cutting gas, including natural gas and additives, the amount of additives added to natural gas is 4g / m 3 The additive is made of the following raw materials in parts by weight: p-xylene 50, ethylbenzene 30, m-xylene 10 and ferrocene 2.

[0024] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0026] A metal cutting gas, including natural gas and additives, the amount of additives added to natural gas is 5g / m 3 ; The additive is made of the following raw materials in parts by weight: p-xylene 52, ethylbenzene 28, m-xylene 12 and ferrocene 1.9.

[0027] The preparation method of this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com