Grinding fluid and preparation method and application thereof

A technology of grinding fluid and aluminum oxide, applied in the field of grinding processing, can solve the problems of affecting the quality of steel balls, pollute the environment, poor cooling performance, etc., and achieve the effects of not easy bacterial pollution, no environmental pollution, and good lubricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

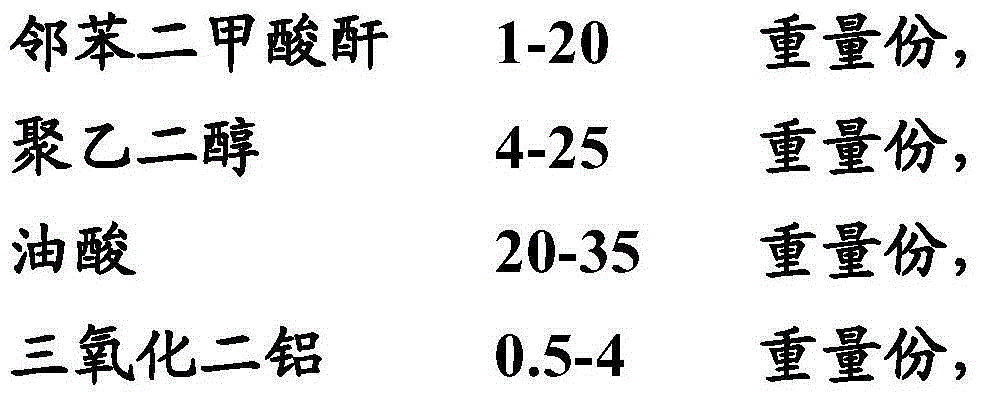

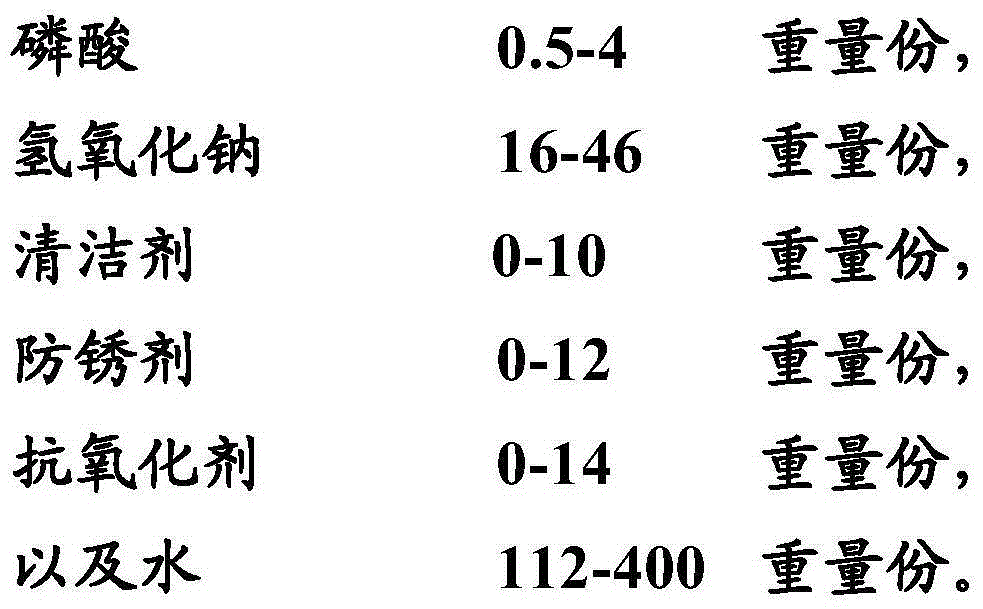

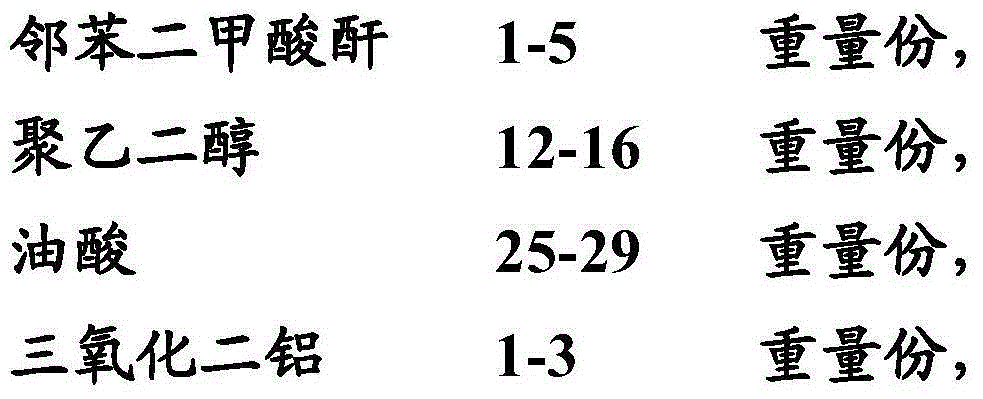

Method used

Image

Examples

Embodiment 1

[0062] 1) Rinse the mixing tank with clean water, then fill in 233kg of water, start the heater, preheat the water to 85°C, add 14kg of PEG1000, 3kg of phthalic anhydride, 27kg of oleic acid, 17kg of sodium hydroxide, 2kg of aluminum oxide and 2kg of phosphoric acid are mixed with water, stirred and mixed at 85°C at a speed of 600r / min for 1 hour.

[0063] 2) Cool down the mixture of step 1) to 55°C, add 6kg of borax, 7kg of benzotriazole, 8kg of triethanolamine and 14kg of sodium hydroxide to the mixture obtained in step 1), and keep stirring at 55°C Mix for 1 hour, stop heating, and cool to room temperature to obtain grinding fluid A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com