Low-gluten beer and preparation method thereof

A technology of beer and gluten, applied in the direction of beer brewing, etc., to achieve the effect of enriching foam, increasing flocculation and sedimentation and modification, and preventing the formation of cold turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

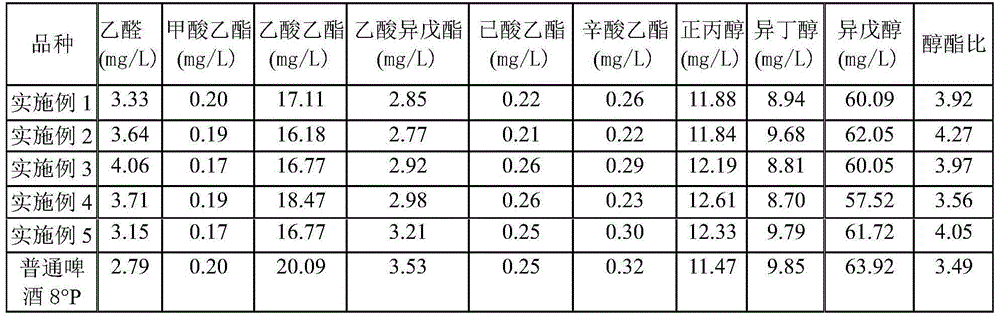

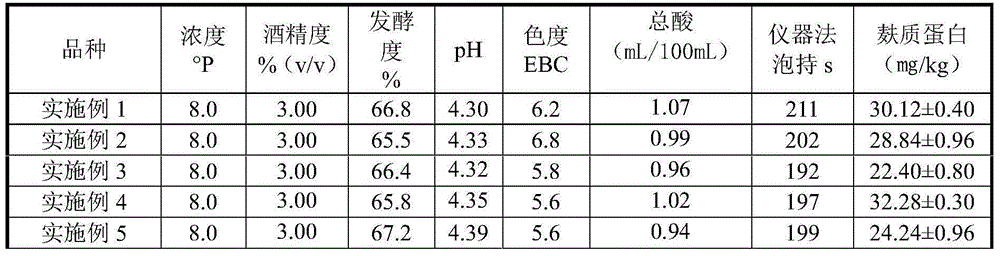

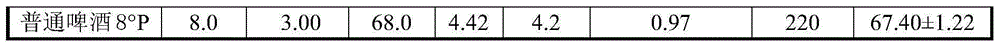

Examples

Embodiment 1

[0037] Embodiment 1: Preparation of 1500L8°P low-gluten beer

[0038] 1) Gelatinization: Take 28kg of rice and 36kg of buckwheat, grind them separately, put water equivalent to 3.0 times the total weight of rice and buckwheat in the gelatinization pot, raise the temperature to 50°C, put in the crushed rice and buckwheat, add 0.02% by weight of amylase (12.8mL), warming up to 95°C, keeping the temperature for 20min;

[0039] 2) Saccharification: Take 76kg of Gaidena barley malt and 12kg of Munich high-flavor malt, grind them separately, add 4.0 times the total weight of barley malt and high-flavor malt into the mash pot, raise the temperature to 45°C, and add the crushed barley Malt and high aroma malt, then add 0.02% and 0.02% of glucoamylase (17.6mL) and protease (17.6mL) accounting for the total weight of barley malt and high aroma malt respectively, heat up to 50°C, and keep warm for 30min;

[0040]3) Combine the mash and filter: put the gelatinized mash into the mash pot,...

Embodiment 2

[0046] Embodiment 2: Preparation of 1500L8°P low-gluten beer

[0047] 1) Gelatinization: Take 30kg of rice and 34kg of buckwheat, grind them separately, put water equivalent to 3.5 times the total weight of rice and buckwheat in the gelatinization pot, raise the temperature to 65°C, put in the crushed rice and buckwheat, add 0.03% by weight of amylase (19.2mL), warming up to 100°C, keeping warm for 30min;

[0048] 2) Saccharification: Take 78kg of Gaidena barley malt and 12kg of Munich high-flavor malt, grind them separately, add 3.0 times the total weight of barley malt and high-flavor malt into the mash tun, raise the temperature to 50°C, and add the crushed barley Malt and high aroma malt, then add 0.01% and 0.03% of glucoamylase (9mL) and protease (27mL) accounting for the total weight of barley malt and high aroma malt respectively, heat up to 55°C, and keep warm for 30min;

[0049] 3) Combine the mash and filter: put the gelatinized mash into the mash pot, control the t...

Embodiment 3

[0055] Embodiment 3: Preparation of 1500L8°P low-gluten beer

[0056] 1) Gelatinization: Take 32kg of rice and 32kg of buckwheat, grind them separately, put water equivalent to 4.0 times the total weight of rice and buckwheat in the gelatinization pot, raise the temperature to 45°C, put in the crushed rice and buckwheat, add 0.025% by weight of amylase (16mL), warming up to 98°C, keeping the temperature for 40min;

[0057] 2) Saccharification: Take 84kg of Gaidena barley malt and 8kg of Munich high-flavor malt, grind them separately, add 3.5 times the total weight of barley malt and high-flavor malt into the mash tun, raise the temperature to 45°C, and add the crushed barley Malt and high aroma malt, then add 0.03% and 0.025% of glucoamylase (27.6mL) and protease (23mL) accounting for the total weight of barley malt and high aroma malt respectively, heat up to 55°C, and keep warm for 20min;

[0058] 3) Combine mash and filter: put the gelatinized mash into the saccharificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com