Method for preparing sulphated polysaccharides from abalone

A technique for sulfated polysaccharides and abalone, applied in the field of preparing polysaccharides and preparing sulfated polysaccharides, can solve the problems of waste of biological resources, environmental pollution, discarding, etc., and achieve the effects of reducing the amount of ethanol, high purity, and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

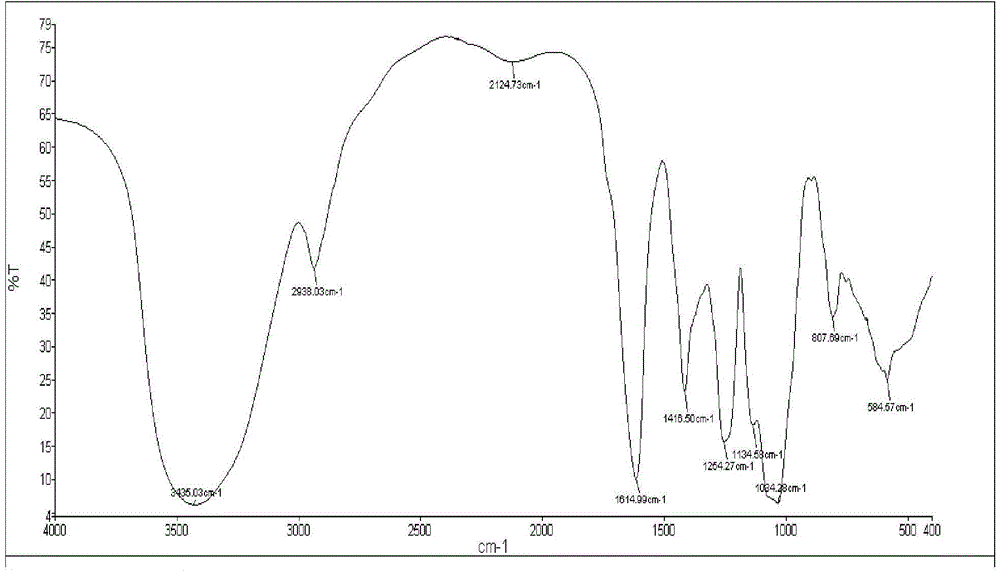

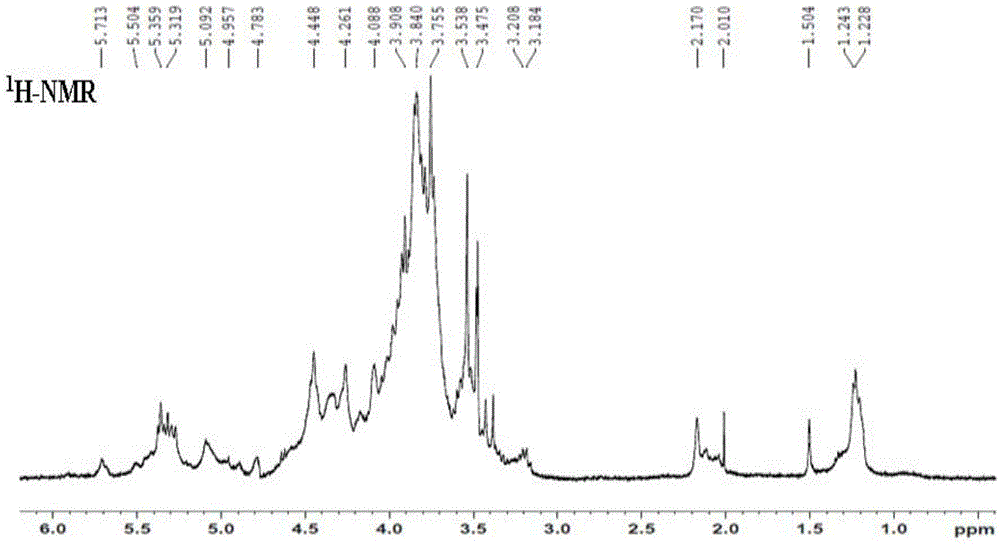

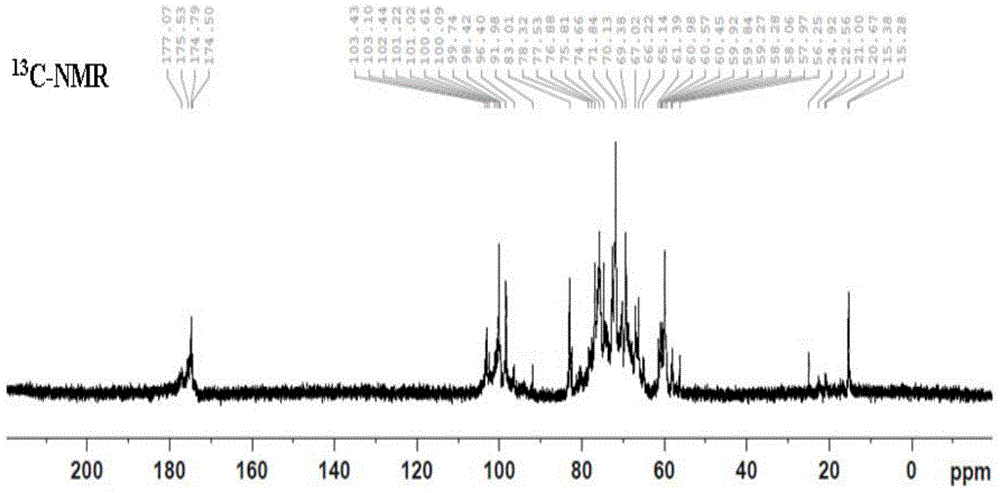

Examples

Embodiment 1

[0036] A preparation method of abalone sulfated polysaccharide, comprising the following steps:

[0037] (1) Use 550 grams of abalone gonad freeze-dried powder as the raw material, after crushing, add 4% sodium chloride aqueous solution, adjust the pH of the sodium hydroxide solution to 8-9, heat and stir at 50-60°C for 2 hours; Serum;

[0038] (2) The supernatant obtained in the above steps repeatedly flows through the D204 strong basic anion exchange resin, so that the sulfated polysaccharide is adsorbed on the ion exchange resin, and the ion exchange resin is washed with water until the effluent is clear and colorless, and then used The 1.4mol / L sodium chloride solution of 4 times the resin volume circulates through the ion exchange resin, and the effluent is collected; the 3mol / L sodium chloride solution of 3 times the resin volume circulates through the ion exchange resin, and the effluent is collected. ; Merge the two effluents;

[0039] (3) Add 3 times the volume of 9...

Embodiment 2

[0045] A preparation method of abalone sulfated polysaccharide, comprising the following steps:

[0046] (1) Take 120 grams of abalone gonad freeze-dried powder as raw material, after crushing, add pH8.0 Tris-acetic acid buffer solution, add 2% trypsin in dry weight of raw material and shake at 37°C for 4 hours, add 2% papain in dry weight of raw material at 50°C Shake for 4 hours, heat and stir at 100°C for 5 minutes; let stand to cool, then centrifuge, and take the supernatant;

[0047] (2) The supernatant obtained in the above steps repeatedly flows through the D204 strong basic anion exchange resin, so that the sulfated polysaccharide is adsorbed on the ion exchange resin, and the ion exchange resin is washed with water until the effluent is clear and colorless, and then used The 1.4mol / L sodium chloride solution of 4 times the resin volume circulates through the ion exchange resin, and the effluent is collected; the 3mol / L sodium chloride solution of 3 times the resin vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com