Method for producing mung bean/pea starch

A technology of pea starch and mung bean, which is applied in the field of food processing, can solve the problems of unguaranteed starch quality, difficult sewage treatment, and large consumption of dissolved oxygen, so as to improve resource utilization, reduce COD and other indicators, and improve purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

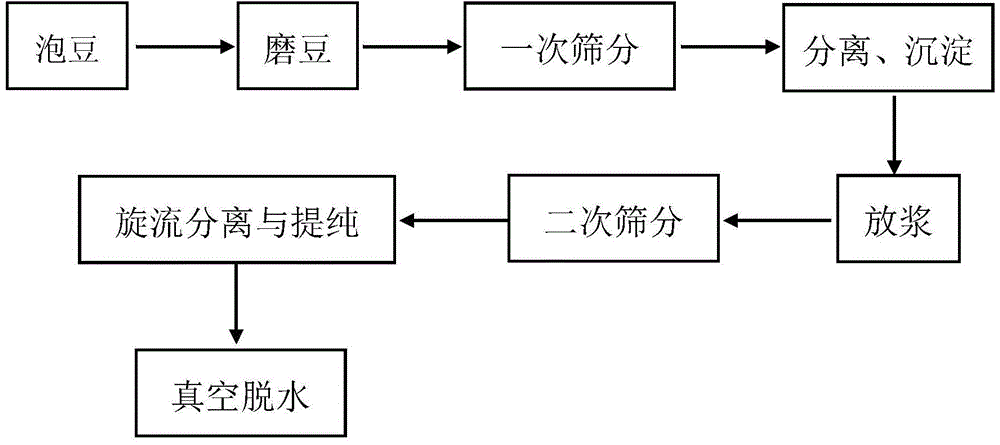

[0035] Such as figure 1 As shown, (1) Soaking beans: Put mung beans / peas in a container and soak them in water. This process is divided into water absorption stage and expansion stage. The main purpose is to soften the tissue, leach some soluble substances, and disperse the protein matrix of embedded starch; The process takes 35 hours. The lactic acid bacteria produced during the soaking process can disintegrate and dissolve the protein network. At the same time, the acidity produced by the lactic acid bacteria changes the pH value of the soaked soybean water from 6.50 to 4.50;

[0036] (2) Grinding beans: The soaked mung beans / peas are cleaned and sieved, and then enter the stainless steel pulverizer to grind into mung bean / pea puree (pH value 4.90). Pulp temperature, the raw pulp temperature should not exceed 23°C;

[0037] (3) Primary screening: the ground pea puree is passed through a pressure curved sieve (300 mesh stainless steel screen) to remove the coarse residue to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com