Skylight-forming lining structure repair method for tunnels

A repair method and lining technology, applied in tunnel lining, tunnel, shaft lining and other directions, can solve problems such as safety accidents, reduce the bearing capacity of lining structures, deteriorate the stress conditions of lining structures, etc. Effects that are easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

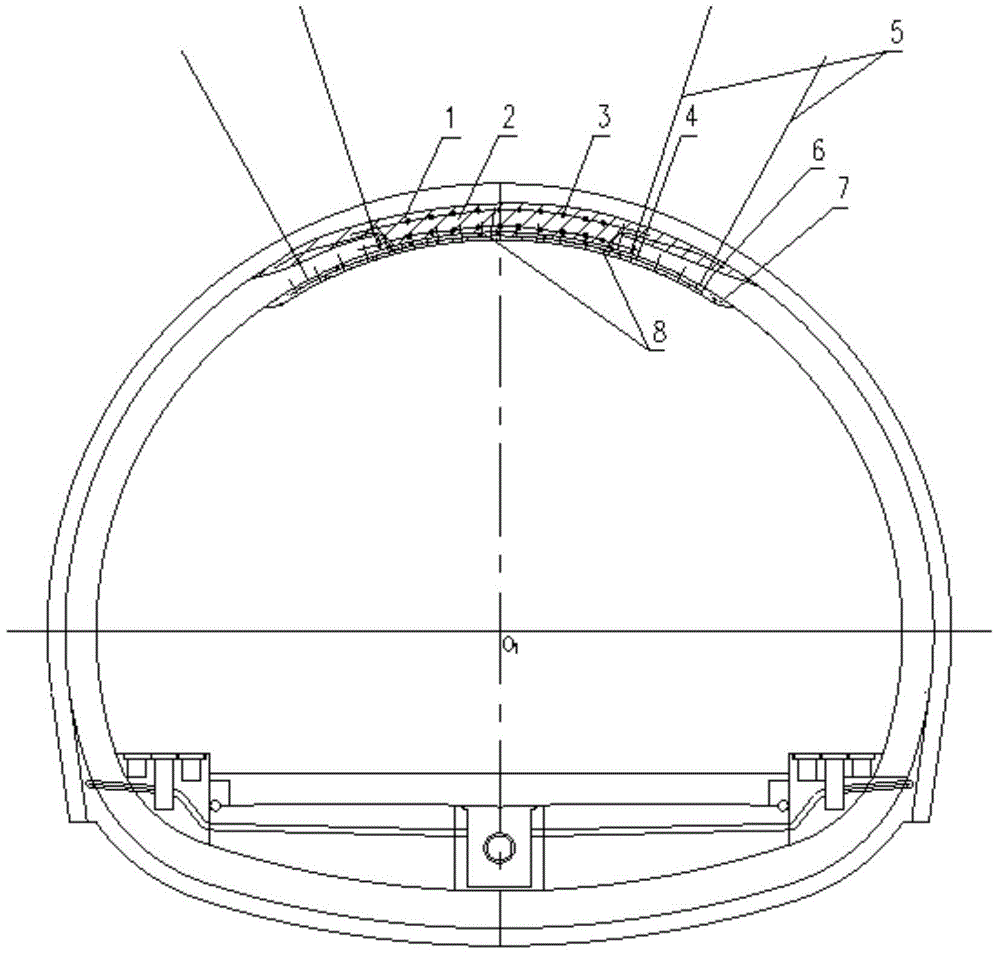

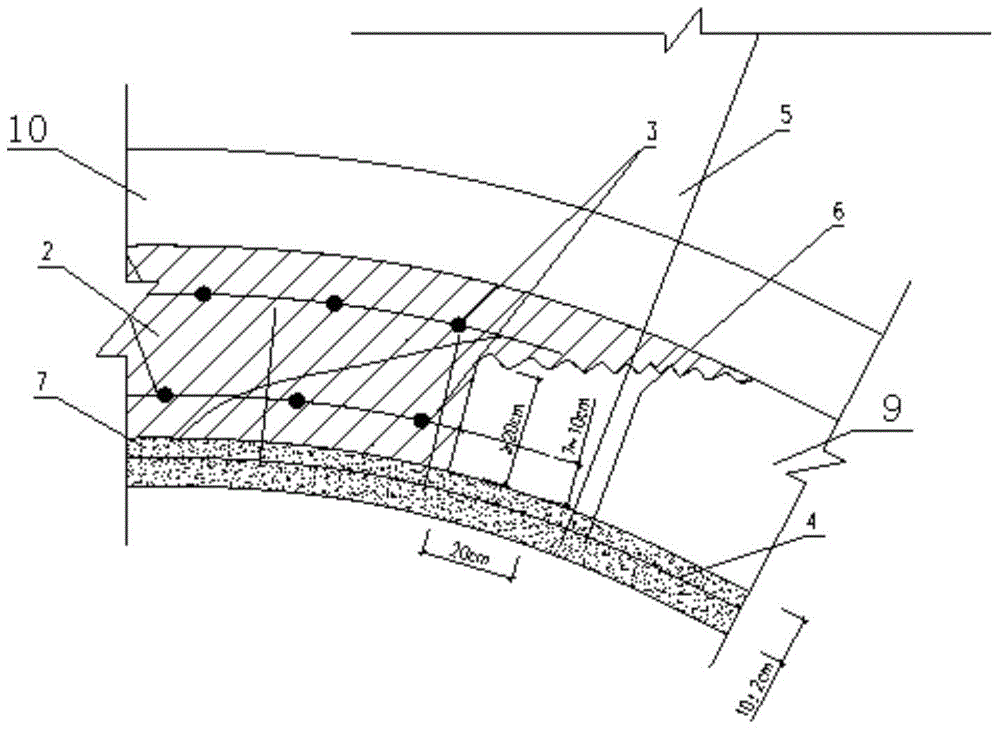

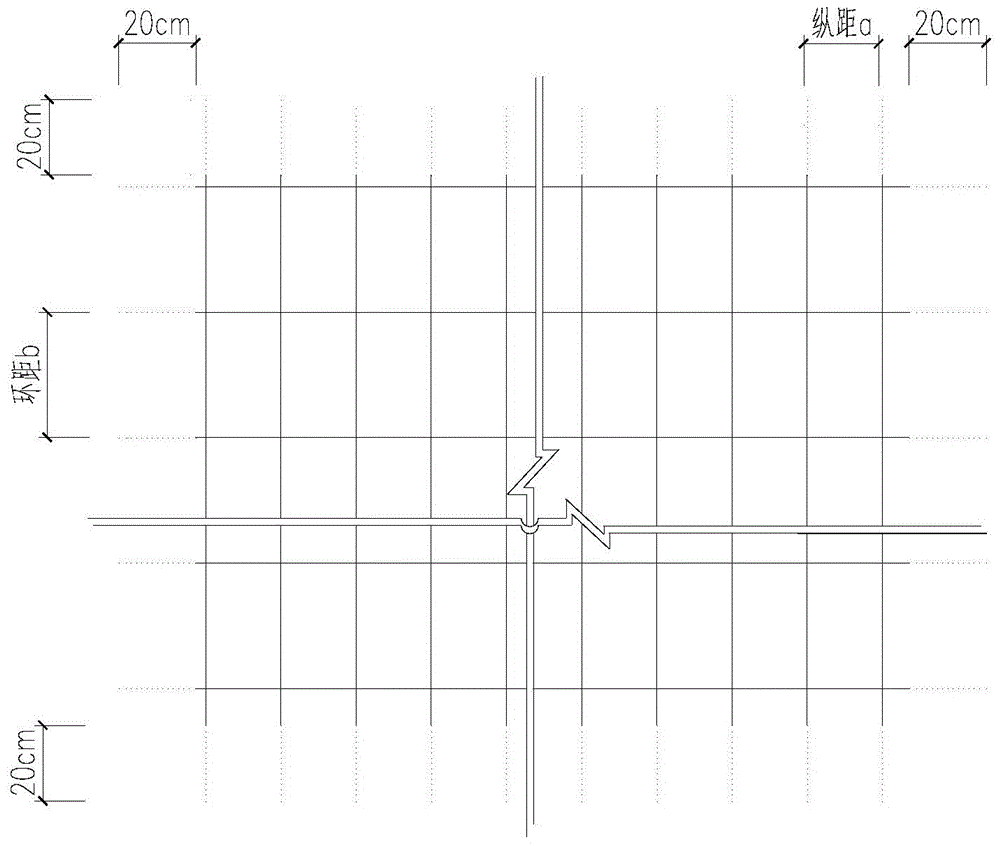

[0032] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] see figure 1 , figure 2 and image 3 , the method for repairing the lining structure of the tunnel skylight, by chiseling out the original defective concrete to form a partial skylight, implanting the lining and repairing steel bars, closing the skylight with layered mesh shotcrete or molded concrete, and then using anchor rods, steel mesh, steel bars Brazing nails and screen shotcrete connect the original defect and the surrounding qualified lining into a whole.

[0034] The shape of the skylight is a regular figure including rectangle, square, quadrilateral or trapezoid with an acute angle greater than 70°

[0035] The original defective part and the surrounding qualified lining are connected as a whole with the hollow anchor rod 5, the lining treatment steel bar 3, the steel mesh 4 and the shotcrete 7.

[0036] see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com