Method for detecting use performance of refractory material

A refractory material and detection method technology, which is applied in the field of refractory material detection, can solve the problems of large difference between the result and the actual situation, limited role in guiding research and development, production and use, and long experimental period, and achieves simple operation and is conducive to large-scale promotion and application , easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be specifically described below in conjunction with the accompanying drawings with embodiments.

[0033] A method for detecting service performance of refractory materials, the steps of the method are as follows:

[0034] 1. Detect the ability of refractory materials to resist thermal stress

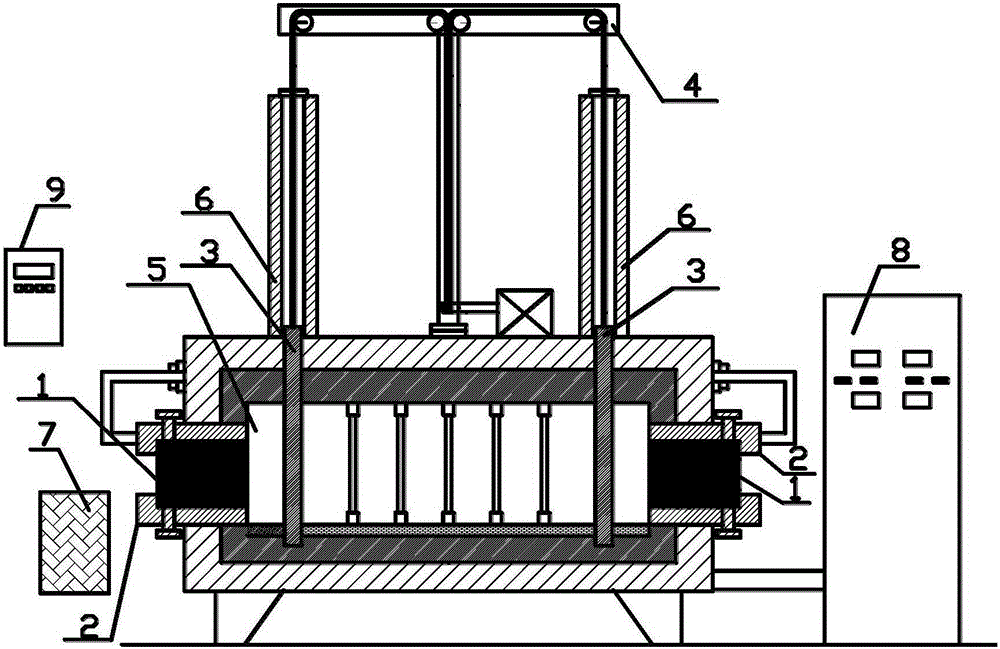

[0035] a. If figure 1 As shown, a temperature-controllable resistance furnace with a maximum heating temperature of 1700°C is used. Two metal furnace doors 2 are installed in the furnace 5 of the resistance furnace. A groove for placing the sample 1 is reserved on the furnace door. The size of the groove is 100×65×65mm, two inserting plates 3 made of refractory materials are set between the heating element of the resistance furnace and the front and rear metal furnace doors 2, and the lifting of the inserting plates 3 is controlled by the electric lifting device 4 outside the furnace;

[0036] b. The refractory material to be tested is made into two sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com