A test method for gas diffusivity in coal under triaxial stress conditions

A technology of triaxial stress and gas diffusion, which is applied in the direction of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of gas diffusion coefficient errors, achieve significant progress and highlight the effect of substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

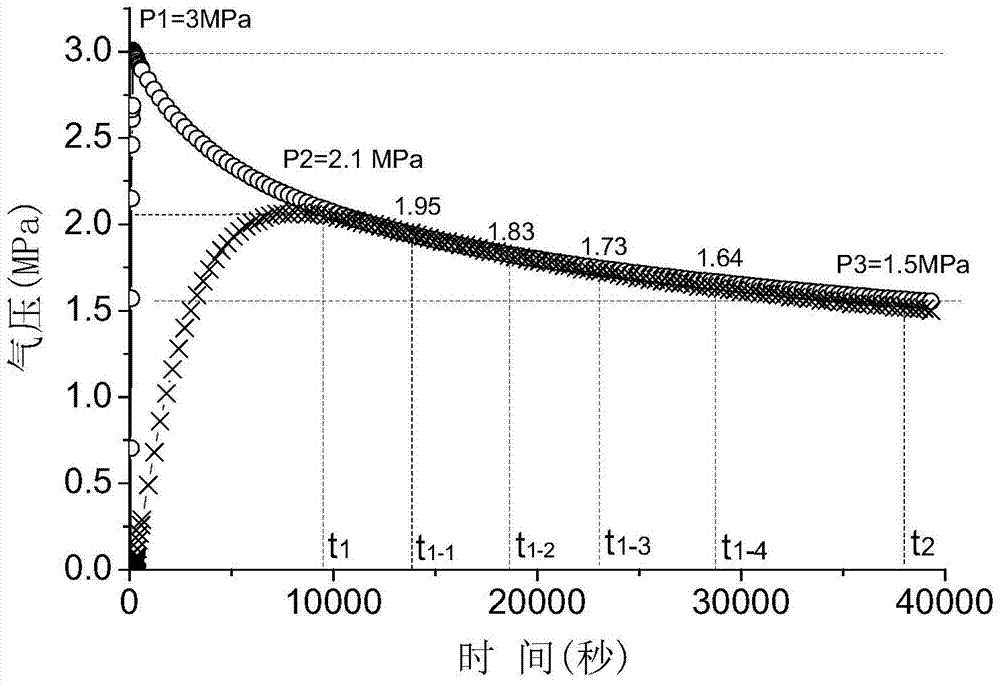

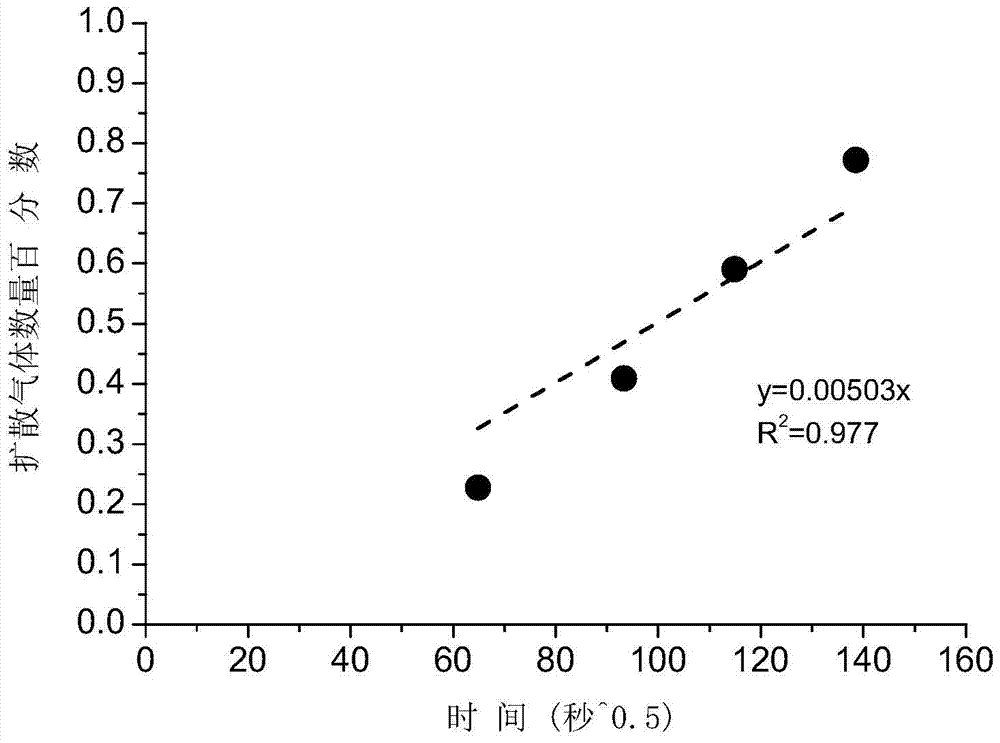

[0029] The technical solution of the present invention will be further described below in conjunction with the drawings and an embodiment. The test condition of the embodiment is that the hoop pressure is 6 MPa and the constant temperature is 293K.

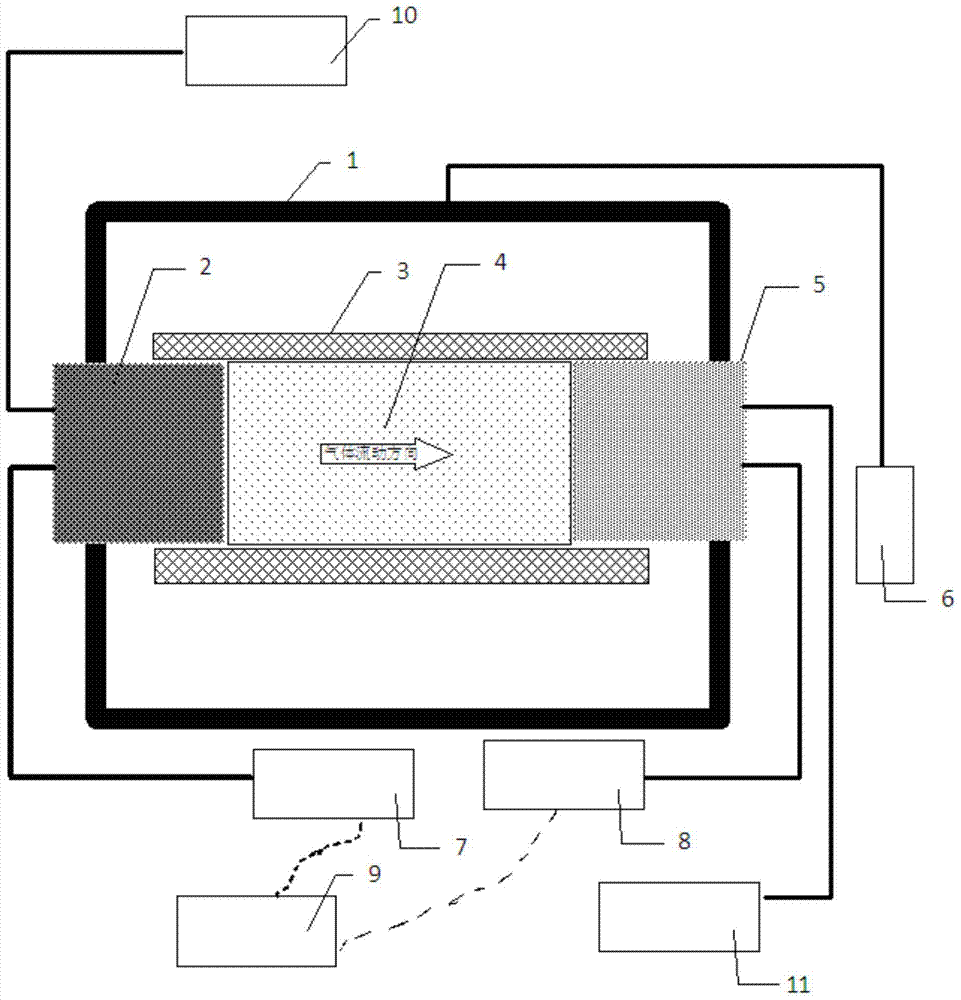

[0030] Such as Figure 1-3 As shown, in the method for testing gas diffusivity in coal under triaxial stress conditions of the present invention, the specific testing steps are as follows:

[0031] The first step: processing and making coal sample test specimens

[0032] Process the whole coal block into a cylindrical shape, with its axial direction perpendicular to the direction of coal seam and parallel to the direction of coal seam; insert the coal sample 4 into the middle of the rubber sleeve 3, and then insert two uncovered cylinders into the rubber sleeve 3 To make the two ends of the coal sample 4 form a closed cavity respectively, one end is used as the gas injection cavity 2 and the other end is used as the gas outlet cavity 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com