Method for thermal desorption treatment of organic polluted soil

A polluted soil and thermal desorption technology, applied in the field of thermal desorption treatment of organic matter-contaminated soil, can solve the problems of low effective utilization rate of agricultural and forestry solid waste, low organic matter content, poor soil quality, etc., and achieve organic carbon content increase, organic matter The effect of increasing content and restoring soil function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: organic matter polluted soil is the organic polluted soil of certain chemical industry site;

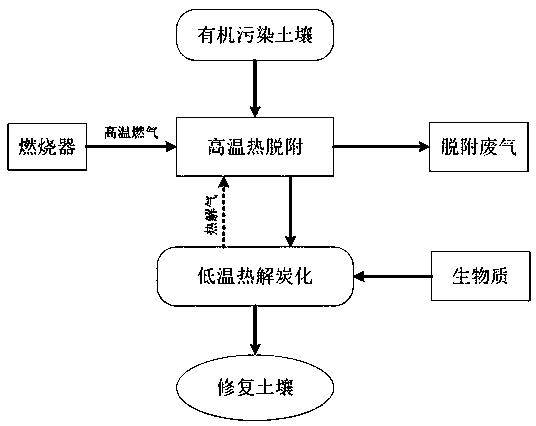

[0022] Such as figure 1 Shown, a method for thermal desorption treatment of organic matter-contaminated soil, the specific steps are as follows:

[0023] (1) The thermal desorption flue gas at a temperature of 500°C (high-temperature gas from the burner) was contacted and reacted with the organic-contaminated soil for 15 minutes to obtain desorbed waste gas and thermally desorbed soil containing organic pollutants;

[0024] (2) Dry the biomass (crop straw) to a moisture content of ≤12%, and crush it to a length of ≤20cm to obtain a biomass segment;

[0025] (3) Mix the thermally desorbed soil in step (1) with the biomass segment in step (2) to obtain a mixture A. At a temperature of 250°C, the biomass in the mixture A is subjected to low-temperature pyrolysis carbonization reaction and the soil is heated Obtain the remediation soil containing organic carbon and...

Embodiment 2

[0027] Embodiment 2: organic matter polluted soil is the organic polluted soil of certain chemical industry site;

[0028] Such as figure 1 Shown, a method for thermal desorption treatment of organic matter-contaminated soil, the specific steps are as follows:

[0029] (1) The thermal desorption flue gas at a temperature of 400°C (the pyrolysis gas obtained by low-temperature pyrolysis and carbonization in step (3)) was contacted with the organic-contaminated soil for 20 minutes to obtain desorption waste gas containing organic pollutants and thermal desorption soil;

[0030] (2) Dry the biomass (a mixture of crop straw, weeds, rice husk, chaff, shrub branches, dead leaves, and sawdust) to a moisture content of ≤10%, and crush it to a length of ≤18cm to obtain a biomass segment;

[0031] (3) Mix the thermally desorbed soil in step (1) with the biomass section in step (2) to obtain a mixture A. At a temperature of 300°C, the biomass in the mixture A is subjected to low-temper...

Embodiment 3

[0033] Embodiment 3: organic matter polluted soil is the organic polluted soil of certain chemical industry site;

[0034] Such as figure 1 Shown, a method for thermal desorption treatment of organic matter-contaminated soil, the specific steps are as follows:

[0035] (1) The thermal desorption flue gas with a temperature of 700°C (high-temperature gas from the burner) is contacted with the organic-contaminated soil countercurrently for 5 minutes to obtain the desorbed waste gas and thermally desorbed soil containing organic pollutants;

[0036] (2) Dry the biomass (a mixture of crop stalks, weeds and rice husk) to a moisture content of ≤9%, and crush it to a length of ≤15cm to obtain a biomass segment;

[0037] (3) Mix the thermally desorbed soil in step (1) with the biomass section in step (2) to obtain a mixture A. At a temperature of 400°C, the biomass in the mixture A is pyrolyzed and carbonized at a low temperature and the soil is heated Obtain remediation soil contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com