Radish-derived nitrogen-doped graded porous carbon and preparation method and application thereof

A hierarchical porous, nitrogen-doped technology, applied in chemical instruments and methods, structural parts, inorganic chemistry, etc., can solve problems such as hindering the transmission and diffusion of reactive substances, small specific surface area of biochar, and destruction of biomass pore structure. Achieve the effect of low cost, high degree of graphitization, and simple operation of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Wash the radish and dry it, then grind and pulverize it, then soak the radish powder with a saturated solution of sodium chloride, zinc chloride and ferric chloride, place it in a water-heated oven at 190°C for 12 hours, and then wash it with deionized water. After drying, carbon solid powder was obtained; the carbon solid powder obtained above was mixed with KOH solid powder at a mass ratio of 1:2, and then activated with potassium hydroxide at 550°C for 2 hours; then washed and deionized with 3mol / L hydrochloric acid The porous carbon was obtained by washing with water to neutrality and drying to obtain porous carbon; the porous carbon was placed in a tube furnace under an ammonia atmosphere and heated to 900 °C at 5︒ / min, kept for 2 hours, and naturally cooled to room temperature to obtain radish-based porous carbon.

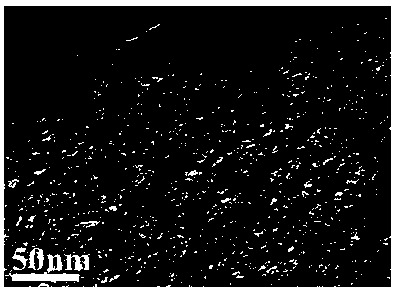

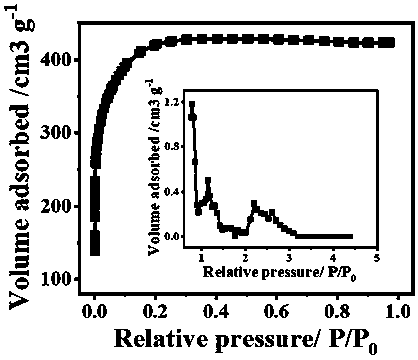

[0036] The radish-derived nitrogen-doped hierarchical porous carbon prepared in Example 1 has a sheet-like structure, such as figure 1As shown, and ha...

Embodiment 2

[0038] Wash the radish and dry it, then grind and pulverize it, then soak the radish powder in a saturated solution of sodium chloride, zinc chloride and ferric chloride, dry it at room temperature and place it in a tube furnace for 3 hours at 400°C, and for 2 hours at 700°C , naturally cooled to room temperature to obtain a carbonized product; the carbonized product obtained above was mixed with KOH solid powder at a mass ratio of 1:2, and then activated with potassium hydroxide at 550°C for 2 hours; then washed with 3 mol / L hydrochloric acid and The porous carbon was obtained by washing with deionized water to neutrality and then drying. The porous carbon was placed in a tube furnace under an ammonia atmosphere and heated to 900 °C at 5 °C / min, kept for 2 h, and cooled naturally to room temperature to obtain a radish-based porous carbon.

[0039] The radish-derived nitrogen-doped hierarchical porous carbon prepared in Example 2 has a sheet-like structure, such as Figure 5 A...

Embodiment 3

[0041] Step 1: Weigh 5 mg of radish-based porous carbon prepared in Example 1 and disperse it into 1 mL of ethanol solution, sonicate for 30 min, add 50 µL of Nafion membrane solution to mix, and then sonicate for 10 min to prepare a catalyst solution. Take 10 µL of the catalyst solution prepared in step 1, and evenly spin-coat it on the glassy carbon electrode to obtain the electrode to be tested.

[0042] The test electrode of the commercial platinum-on-carbon catalyst was prepared by the method of step 1.

[0043] Step 2: The electrode prepared in step 1 was used as the working electrode, the carbon rod was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode to assemble a three-electrode system for electrochemical performance testing. 0.1 mol / L KOH solution was used as the electrolyte. Such as Figure 6 As shown, the radish-based porous carbon exhibits excellent catalytic activity for oxygen reduction, which is superior to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com