Modified poly(arylene ether) resin composition comprising mineral oil and wire prepared from the same

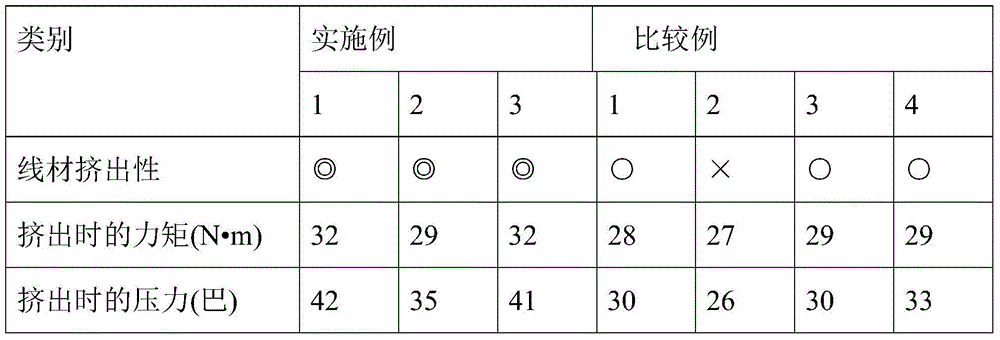

A technology of resin composition and arylene ether, which is applied in the direction of conductors, electrical components, circuits, etc., can solve the problems of reduced productivity, increased cost of raw materials, expensive, etc., to achieve increased productivity, reduced raw material costs, and excellent extrusion properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

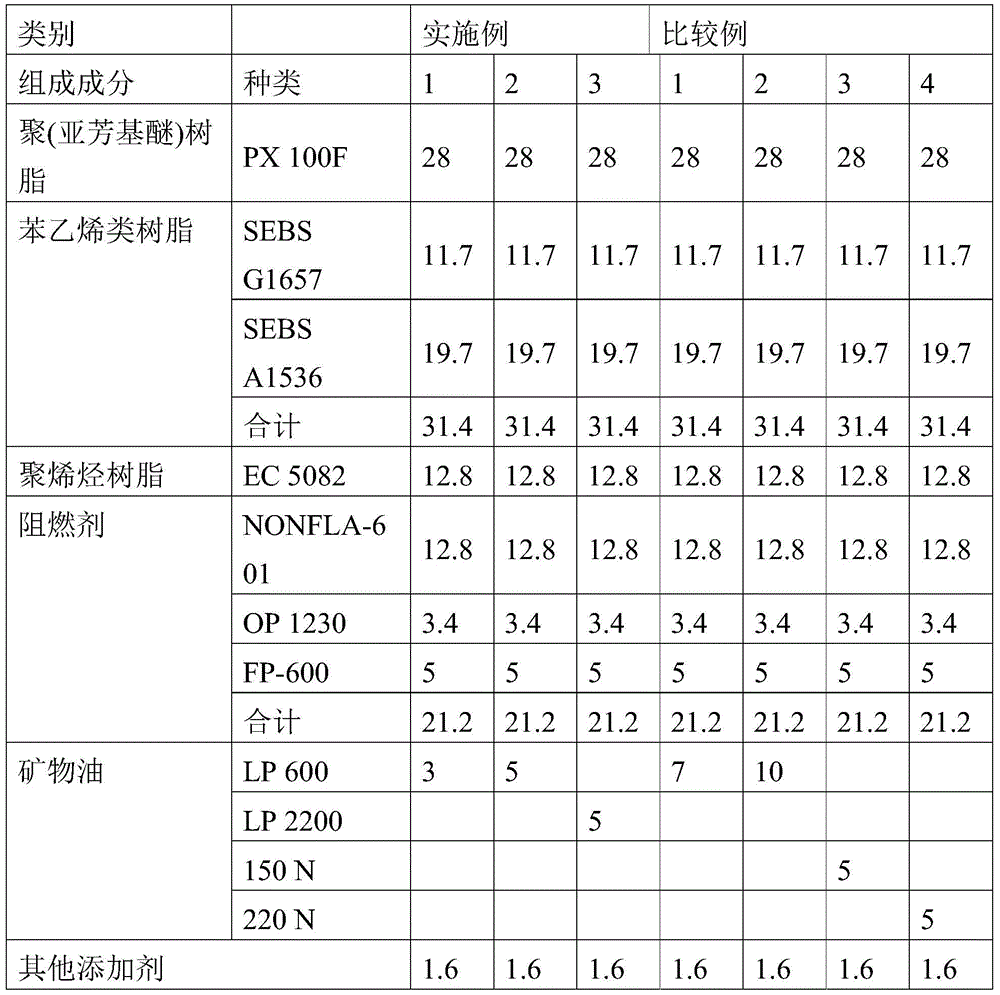

[0020] The present invention relates to a modified poly(arylene ether) resin composition, which comprises: a mixed resin containing poly(arylene ether) resin, styrene resin and polyolefin resin, a flame retardant and mineral oil, Wherein, the weight average molecular weight of the mineral oil is 460 to 1000 g / mol.

[0021] In one embodiment, the hybrid resin may include poly(arylene ether) resin, styrenic resin, and polyolefin resin.

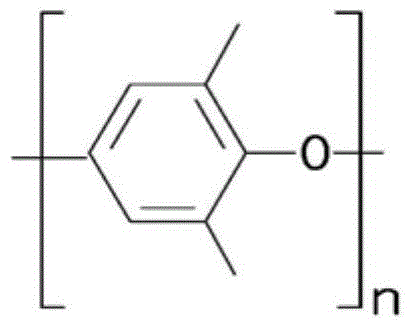

[0022] In one embodiment, the poly(arylene ether) resin is a homopolymer of a compound represented by the following Chemical Formula 1 or a copolymer containing a compound represented by the following Chemical Formula 1:

[0023] [chemical formula 1]

[0024] -Ar(R 1 R 2 R 3 R 4 )-O-

[0025] Among them, R 1 , R 2 , R 3 and R 4 is a substituent of aryl (Ar), each independently or simultaneously hydrogen, chlorine, bromine, iodine, methyl, ethyl, propyl, aryl, phenyl, methylbenzyl, chloromethyl, bromine Methyl, cyanoethyl, cyano, metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| aniline point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com