Lithium-ion secondary cell and method for manufacturing same

A secondary battery, lithium ion technology, used in secondary battery manufacturing, secondary battery, electrode manufacturing, etc., can solve the problems of high energy, high temperature heating, high voltage, etc., to avoid internal short circuits and ensure the adhesion strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060]

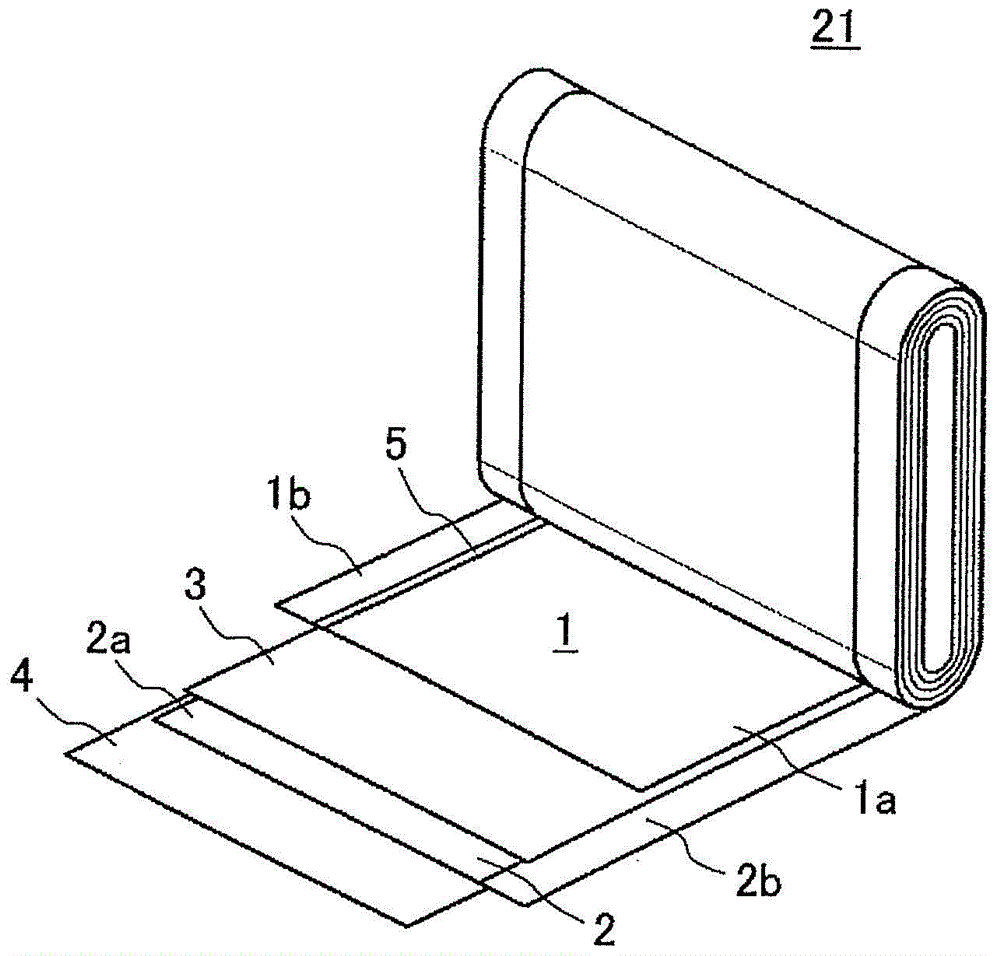

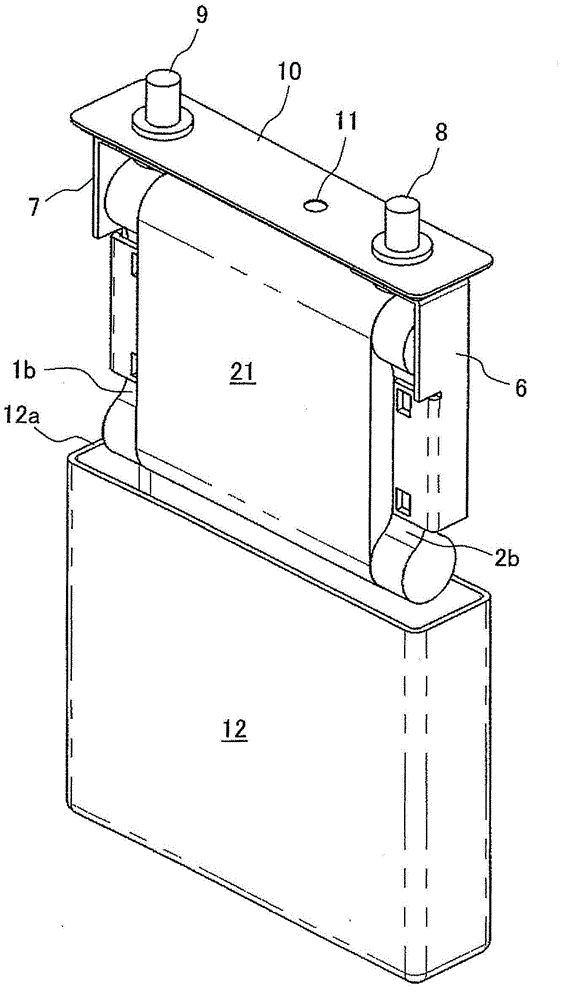

[0061] A paste is applied on both sides of an aluminum foil with a thickness of 20 μm as the positive electrode current collector. A paste obtained by mixing polyvinylidene fluoride (PVDF) as an agent in a weight ratio of 85:10:5, and adding and mixing N-methylpyrrolidone (NMP) as a dispersion solvent. The positive electrode mixture layer 1a has a width of 80 mm and a coating amount of 130 g / m 2 conditions for coating. Immediately thereafter, the insulating layer 5 is applied in the vicinity of the boundary between one side and the uncoated portion.

[0062]The insulating layer 5 was coated with a paste having a solid content of 30 wt % obtained by dispersing alumina powder having a particle diameter of 0.8 μm as an insulating material in a solution in which PVDF was dissolved in NMP. Then, the mixed layer 13 is formed between the positive electrode mixture layer 1 a and the insulating layer 5 by standing still for a predetermined mixing time before being placed i...

Embodiment 2

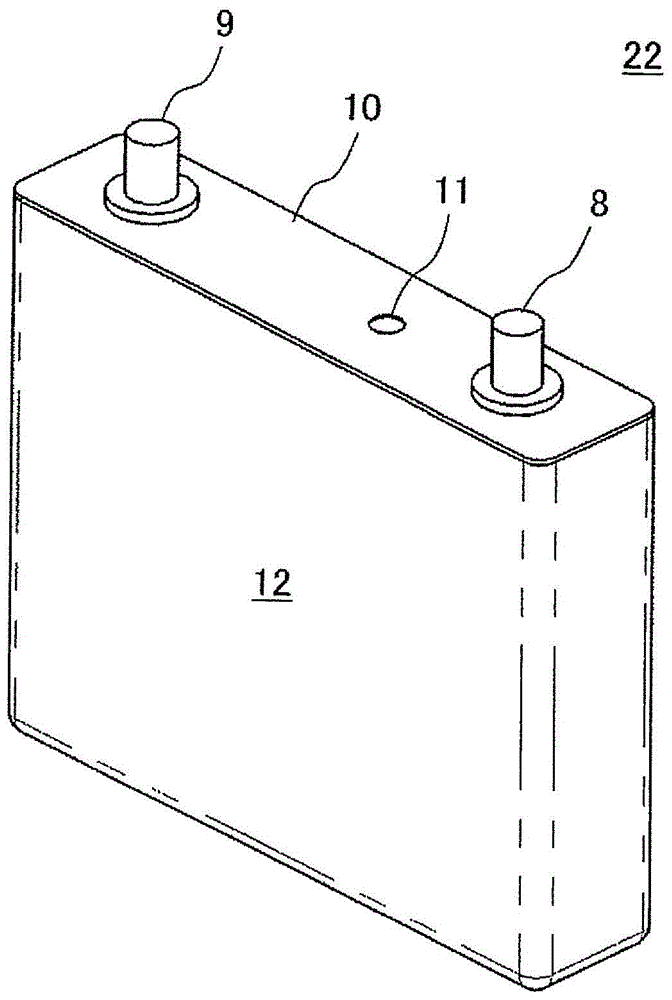

[0072] The lithium ion secondary battery 22 of Example 2 has the same structure as the lithium ion secondary battery 22 described in Example 1, except for the insulating layer 5 . Therefore, only the insulating layer 5 will be described.

[0073]

[0074] About the insulating layer 5, the solution which melt|dissolved the mixture of a bisphenol-A type epoxy resin and an acrylic copolymer in NMP was applied, and it manufactured using the method similar to Example 1 except this. As for the epoxy-based resin, resins other than those described above may be used.

[0075] Except for this, the lithium ion secondary battery 22 was produced in the same manner as in Example 1.

[0076] In the positive electrode 1 manufactured in embodiment 1, 2, such as Figure 6 As shown, by forming the mixed layer 13 , sufficient adhesion strength is ensured, and no gap is formed between the positive electrode mixture layer 1 a and the insulating layer 5 , and the risk of internal short circuit c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com