Processing method for instant ruditapes philippinarum food

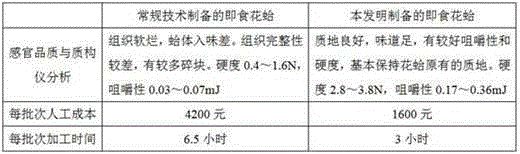

A processing method and a technology for clams, which are applied in the field of instant clams food processing, can solve the problems of soft and rotten taste of flying clams, soft and rotten taste, and long pickling time, so as to solve the problem of large loss, solve the problem of tissue soft and rotten, and strengthen the The effect of chewing and palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A processing method of instant clam food comprises the following steps: shell opening by steam, meat taking by vibration, vacuum microwave dehydration, microwave frying, sterilization, and vacuum packaging.

[0026] Steam shell opening: steam pressure 0.1MPa, time 3min, until the clam shell is completely opened, at the same time collect clam juice, vacuum concentration, concentration vacuum degree 0.01MPa, concentration to a solid content of 16%, to obtain clam juice concentrate.

[0027] Vibrating meat extraction: the fully opened clams are passed through the vibrating screen conveyor belt to separate the shell and meat, and the vibration frequency of the screen is 180 times / min.

[0028] Vacuum microwave dehydration: vacuum microwave dehydration of clam meat after removing belly and washing, microwave intensity 3000W / kg, vacuum degree 40kPa, material thickness 5mm, dehydration until water content is 50%; put clam meat into seasoning In the juice, make the clam meat in...

Embodiment 2

[0032] A processing method of instant clam food comprises the following steps: shell opening by steam, meat extraction by vibration, vacuum microwave dehydration, microwave frying, sterilization, and vacuum packaging.

[0033]Steam shell opening: Steam pressure 0.2MPa, time 7min, until the clam shell is completely opened, at the same time collect clam juice, vacuum concentration, concentration vacuum degree 0.02MPa, concentration to a solid content of 20%, to obtain clam juice concentrate.

[0034] Vibrating meat extraction: the fully opened clams are passed through the vibrating screen conveyor belt to separate the shell and meat, and the vibration frequency of the screen is 250 times / min.

[0035] Vacuum microwave dehydration: vacuum microwave dehydration of clam meat after removing belly and washing, microwave intensity 4000W / kg, vacuum degree 70kPa, material thickness 10mm, dehydration to 60% water content; put clam meat into seasoning In the juice, make the clam meat inha...

Embodiment 3

[0039] A processing method of instant clam food comprises the following steps: shell opening by steam, meat taking by vibration, vacuum microwave dehydration, microwave frying, sterilization, and vacuum packaging.

[0040] Steam shell opening: steam pressure 0.15MPa, time 5min, until the clam shell is completely opened, at the same time collect clam juice, vacuum concentration, concentration vacuum degree 0.015MPa, concentration to a solid content of 18%, to obtain clam juice concentrate.

[0041] Vibrating meat extraction: the fully opened clams are passed through the vibrating screen conveyor belt to separate the shell and meat, and the vibration frequency of the screen is 200 times / min.

[0042] Vacuum microwave dehydration: vacuum microwave dehydration of clam meat after removing belly and washing, microwave intensity 3500W / kg, vacuum degree 50kPa, material thickness 8mm, dehydration until water content is 55%; put clam meat into seasoning In the juice, make the clam meat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com