A tail gas vacuum acid removal filter for a decompression diffusion furnace

A diffusion furnace and filter technology, which is applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of inability to apply decompression diffusion exhaust gas treatment, weak corrosion resistance, and unsuitable decompression diffusion exhaust gas treatment. and other problems, to achieve the effect of avoiding exhaust gas corrosion, preventing exhaust gas corrosion and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

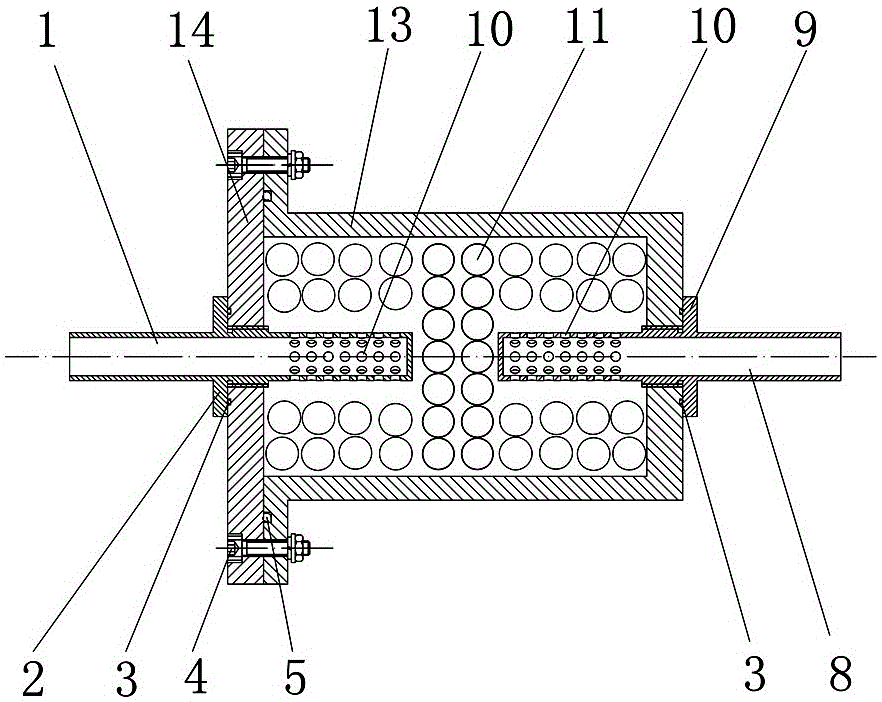

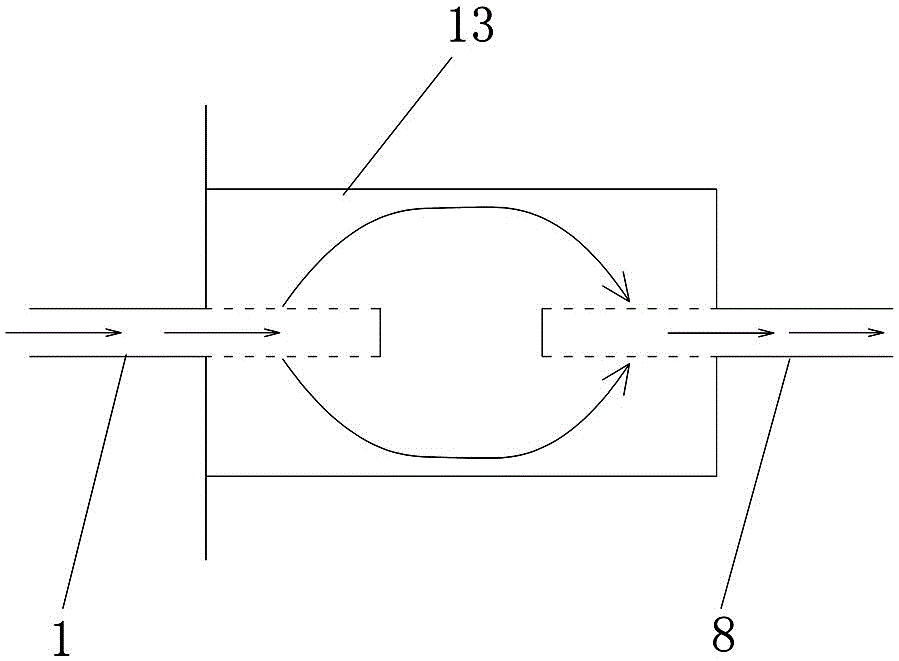

[0024] Such as figure 1 As shown, the tail gas vacuum deacidification filter for the decompression diffusion furnace of the present embodiment includes a sealed filter cylinder 13 and an air inlet pipe 1 and an air outlet pipe 8 respectively arranged at both ends of the filter cylinder 13, and the air outlet of the air inlet pipe 1 end is communicated with the filter cylinder 13, the air inlet end of the air outlet pipe 8 is communicated with the filter cylinder 13, the filter cylinder 13 is filled with adsorbent 11 for acid removal, and the outlet end of the air inlet pipe 1 is provided with multiple The ventilation holes 10 of the air outlet of the trachea 1, the air inlet end of the outlet pipe 8 is provided with a plurality of ventilation holes 10 for the air inlet of the outlet pipe 8, and the particle diameter of the adsorbent 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com