Method for using mixed solvent to separate ethyl alcohol-acetic acid isopropyl ester azeotrope by continuous extractive distillation

A technology of isopropyl acetate, extraction and rectification, which is applied in the field of continuous extraction and rectification of mixed solvents to separate ethanol-isopropyl acetate azeotrope, can solve problems such as equipment corrosion, and achieve the effect of low energy consumption and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

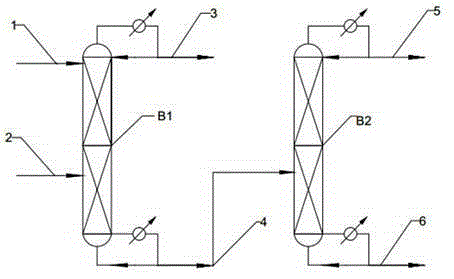

[0015] (1) A new process of ethanol-isopropyl acetate azeotrope extraction, rectification and separation, the process flow chart is as follows figure 1 shown. The theoretical plate number of extractive distillation column B1 is 80. With 90wt% N-methylpyrrolidone and 10wt% [Emim] [BF 4 ] As a mixed extractant, add from the 5th theoretical plate, the flow rate is 400kg / hr. The mixture of ethanol and isopropyl acetate is added from the 42nd theoretical plate, the flow rate is 100kg / hr, the mass fraction of ethanol is 50%, B1 is operated under normal pressure, the top reflux ratio is 7:1, the top The temperature is 70-80°C, the temperature of the tower bottom is 160-180°C, and the top product is analyzed by gas chromatography to obtain an ethanol product with a purity higher than 99.5%. (2) The bottom of the extractive distillation tower B1 enters the solvent recovery tower B2. The solvent recovery tower has 50 theoretical plates. ~200°C. The purity of the isopropyl acetate o...

Embodiment example 2

[0017] (1) The process flow of the two towers of the extractive distillation tower is the same as in Example 1. With 90wt% N-methylpyrrolidone and 10wt% [Bmim] [BF 4 ] Do mixed extractant, B1 theoretical plate number is 80, feeds from the 3rd theoretical plate, flow rate is 500kg / hr. The mixture of ethanol and isopropyl acetate is added from the 65th theoretical plate, the flow rate is 100kg / hr, and the composition is the same as in Example 1. B1 operates at normal pressure with a reflux ratio of 6:1. At this time, the temperature at the top of the tower is 70-80°C, and the temperature at the bottom of the tower is 160-180°C. The top product is analyzed by gas chromatography to obtain an ethanol product with a purity higher than 99.5%. (2) The contents of the bottom of the extractive distillation tower B1 enter the solvent recovery tower B2. The solvent recovery tower has 40 theoretical plates. 180~200℃. The purity of the isopropyl acetate obtained at the top of the tower...

Embodiment example 3

[0019] The two-tower flow process of the extractive distillation tower is the same as the implementation case 1, and the extractant is selected from 90wt% N-methylpyrrolidone, 5wt% [Bmim] [BF 4 ], and 5wt%[Emim][BF 4 ] Composition of the mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com