Mold cleaning device for sealing gasket of drum-type washing machine and production process thereof

A technology for drum washing machines and gaskets, which is applied in the field of mold cleaning equipment and production technology for drum washing machine gaskets. It can solve problems such as odor, poor impact resistance, and short service life during use, and achieve strong ozone resistance. , enhance efficiency, enhance aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

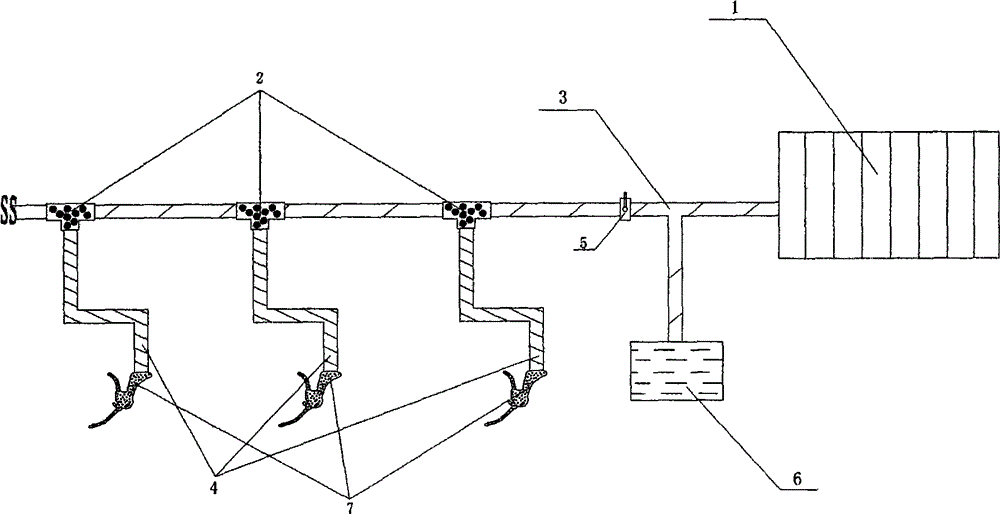

Image

Examples

Embodiment 1

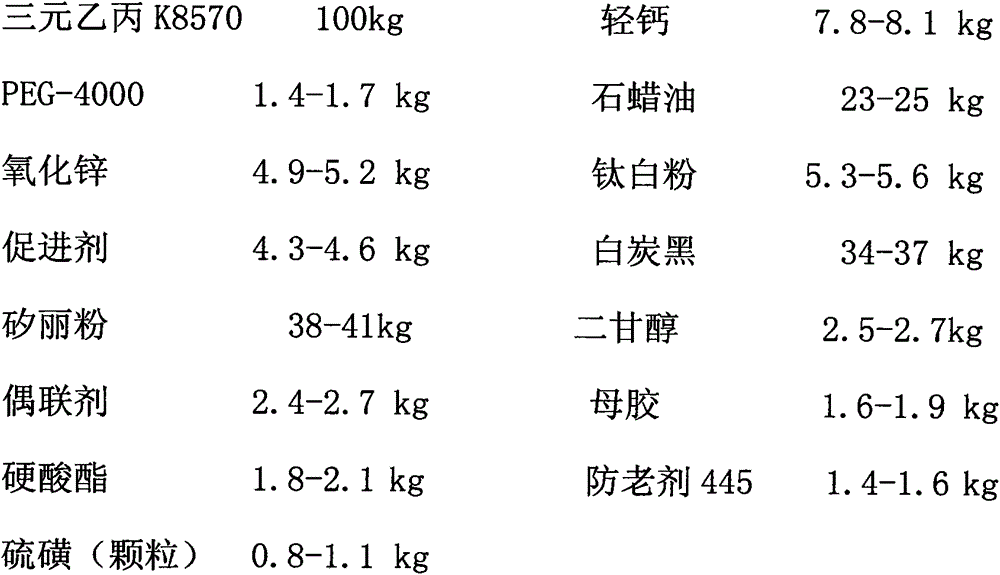

[0028] Step One, Ingredients

[0029] EPDM K8570100kg, light calcium 7.8kg, PEG-40001.4kg paraffin oil 23kg, zinc oxide 4.9kg, titanium dioxide 5.3kg, accelerator 4.3kg, white carbon black 34kg, silicon powder 38kg, diethylene glycol 2.5kg, 2.4kg of coupling agent, 1.6kg of masterbatch, 1.8kg of stearic acid ester, 4451.4kg of anti-aging agent, 0.8kg of sulfur (granule), as the raw material for preparing ring pad:

[0030] The second step, rubber mixing

[0031] Put the raw materials that have been weighed to prepare the annular pad body into the rubber mixing machine for rubber mixing;

[0032] The third step, filter gel and the next piece

[0033] Filter the rubber that has been trained by the rubber mixer, and then slice it according to the entrance width of the injection machine to make a film;

[0034] The fourth step, injection vulcanization molding

[0035] The film is fed into the injection machine, the temperature in the injection machine is controlled at 210° C.,...

Embodiment 2

[0039] Step One, Ingredients

[0040] EPDM K8570100kg, light calcium 7.9kg, PEG-40001.6kg paraffin oil 25kg, zinc oxide 5.1kg, titanium dioxide 5.6kg, accelerator 4.5kg, white carbon black 36kg, silicon powder 39kg, diethylene glycol 2.6kg, 2.6kg of coupling agent, 1.7kg of masterbatch, 1.9kg of stearic acid ester, 4451.5kg of anti-aging agent, 0.9kg of sulfur (granule), as raw materials for the preparation of colloid:

[0041] The second step, rubber mixing

[0042] Put the raw materials that have been weighed to prepare the annular pad body into the rubber mixing machine for rubber mixing;

[0043] The third step, filter gel and the next piece

[0044] Filter the rubber that has been trained by the rubber mixer, and then slice it according to the entrance width of the injection machine to make a film;

[0045] The fourth step, injection vulcanization molding

[0046] The film is fed into the injection machine, the temperature in the injection machine is controlled at 220...

Embodiment 3

[0050] Step One, Ingredients

[0051] EPDM K8570100kg, light calcium 8kg, PEG-40001.5kg paraffin oil 24kg, zinc oxide 5kg, titanium dioxide 5.5kg, accelerator 4.4kg, white carbon black 35kg, silicon powder 40kg, diethylene glycol 2.5kg, coupling Agent 2.5kg, masterbatch 1.8kg, stearic acid ester 2kg, antioxidant 4451.5kg, sulfur (granule) 1kg, as the raw material of preparation link colloid:

[0052] The second step, rubber mixing

[0053] Put the raw materials that have been weighed to prepare the annular pad body into the rubber mixing machine for rubber mixing;

[0054] The third step, filter gel and the next piece

[0055] Filter the rubber that has been trained by the rubber mixer, and then slice it according to the entrance width of the injection machine to make a film;

[0056] The fourth step, injection vulcanization molding

[0057] The film is fed into the injection machine, the temperature in the injection machine is controlled at 225° C., and the time is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com