A kind of asphalt smoke suppressant and smoke suppressant pitch based on the smoke suppressant and preparation method thereof

A technology of smoke suppressant and asphalt, applied in building components, climate change adaptation, building insulation materials, etc., can solve problems such as increasing construction difficulty, and achieve the effects of improving durability, reducing volatilization, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of asphalt smoke suppressant, according to mass percentage, this pitch smoke suppressant comprises 20% zeolite, 5% diatomite, 15% pumice stone, 15% graphite, 3% carbon nanotube and 42% Titanium dioxide. Wherein, the carbon nanotubes are single-walled carbon nanotubes.

[0034] The preparation method of smoke-suppressing pitch: according to mass percentage, first cool 20% of zeolite, 5% of diatomaceous earth, 15% of pumice, 15% of graphite, 3% of carbon nanotube and 42% of titanium dioxide to 0°C, and then put it into a dry In the mixer, the asphalt smoke suppressant can be obtained by mixing evenly.

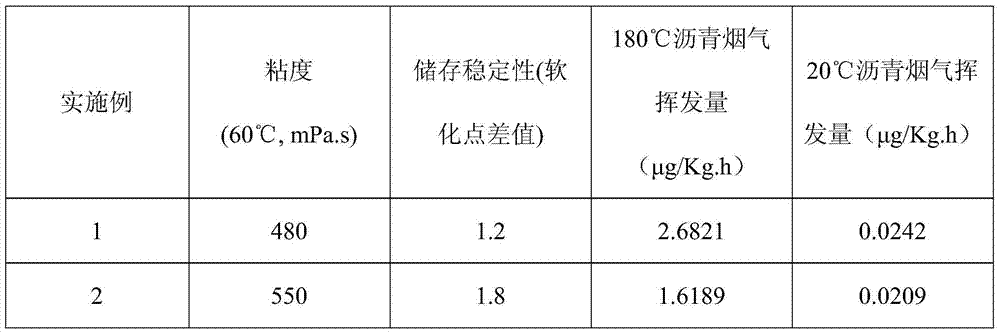

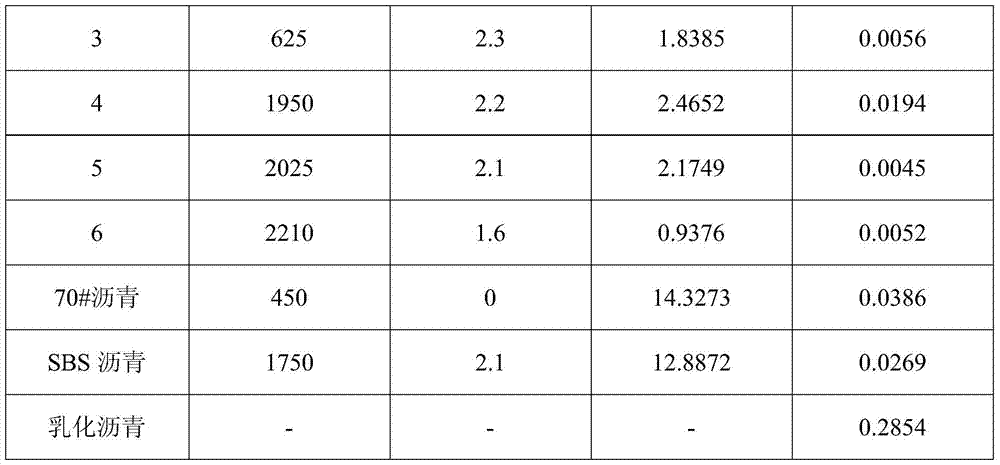

[0035] Heat 70# asphalt to 165°C, and stir at 1500rpm / min, add asphalt smoke suppressant while stirring, and then stir for 0.5 hours to make it blend evenly to obtain smoke suppressant pitch. The mass percentage is 2%. Performance indicators are shown in Table 1.

Embodiment 2

[0037]An asphalt smoke suppressant, which comprises 35% zeolite, 10.5% diatomite, 10% pumice, 1% graphite, 0.5% carbon nanotube and 43% titanium dioxide according to mass percentage . Among them, the carbon nanotubes are a mixture of single-walled carbon nanotubes and double-walled carbon nanotubes.

[0038] The preparation method of smoke-suppressing asphalt: according to mass percentage, first cool 35% of zeolite, 10.5% of diatomite, 10% of pumice, 1% of graphite, 0.5% of carbon nanotube and 43% of titanium dioxide to 5°C, and then put it into a dry In the mixer, the asphalt smoke suppressant can be obtained by mixing evenly.

[0039] Heat 70# asphalt to 175°C and stir at 2000rpm / min, add asphalt smoke suppressant while stirring, and then stir for 1.0 hour to make it blend evenly to obtain smoke suppressant pitch, of which the smoke suppressant is The mass percentage is 5%. Performance indicators are shown in Table 1.

Embodiment 3

[0041] A kind of asphalt smoke suppressant, according to mass percentage, this pitch smoke suppressant comprises 5% zeolite, 50% diatomite, 1% pumice, 5% graphite, 0.1% carbon nanotube and 38.9% Titanium dioxide. Wherein, the carbon nanotubes are a mixture of double-walled carbon nanotubes and multi-walled carbon nanotubes.

[0042] The preparation method of smoke-suppressing pitch: according to mass percentage, first cool 5% zeolite, 50% diatomaceous earth, 1% pumice, 5% graphite, 0.1% carbon nanotube and 38.9% titanium dioxide to 10°C, and then put it into a dry place In the mixer, the asphalt smoke suppressant can be obtained by mixing evenly.

[0043] Heat 70# asphalt to 155°C and stir at 3000rpm / min, add asphalt smoke suppressant while stirring, and then stir for 3.0 hours to make it blend evenly to obtain smoke suppressant pitch, in which the smoke suppressant pitch is The mass percentage of smoke agent is 8%. Performance indicators are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com