Coating and preparation method thereof

A coating and mass fraction technology, used in polyester coatings, antifouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve problems such as wall dust, achieve long-term cleaning, purify toxic substances, and avoid inconvenient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

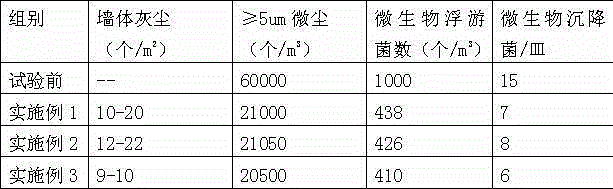

Examples

Embodiment 1

[0026] The composition is: 20g of water-based resin, 10g of polyurethane emulsion, 10g of diatomite, 8g of rare earth, 3g of polyacrylamide, 2g of imidazoline, 0.5g of hydroxymethyl cellulose, 1g of nano additives, 5g of adsorption additives, 1g of bactericide, 0.5g film-forming agent, 0.3g defoamer, 0.5g leveling agent, 0.2g wetting agent, 0.5g dispersant, 0.4g thickener, 2g titanium dioxide and 20g deionized water.

[0027] Among them, the water-based resin is composed of polyester resin, alkyd resin, and silicone resin, of which: 9.2g of polyester resin, 4.6g of alkyd resin, and 6.2g of silicone resin;

[0028] Wherein, the film forming agent is a mixture of polyvinyl alcohol, povidone and gelatin, wherein, polyvinyl alcohol 0.17g, povidone 0.17g and gelatin 0.16g;

[0029] Among them, the nano additives are composed of silica nanoparticles, zinc oxide nanoparticles, zirconia nanoparticles and silicon carbide nanofibers, wherein: 0.22g of silica nanoparticles, 0.44g of zinc...

Embodiment 2

[0038] The composition is: 30g of water-based resin, 15g of polyurethane emulsion, 15g of diatomite, 15g of rare earth, 8g of polyacrylamide, 4g of imidazoline, 1g of hydroxymethyl cellulose, 3g of nano additives, 10g of adsorption additives, 3g of bactericide, and Film agent 1g, defoamer 1g, leveling agent 1g, wetting agent 0.5g, dispersant 1g, thickener 1g, titanium dioxide 4g and deionized water 30g.

[0039] Among them, the water-based resin is composed of polyester resin, alkyd resin, and silicone resin, of which: 12g of polyester resin, 8.4g of alkyd resin, and 9.6g of silicone resin;

[0040] Wherein, the film-forming agent is a mixture of polyvinyl alcohol, povidone and gelatin, wherein: 0.3 g of polyvinyl alcohol, 0.4 g of povidone and 0.3 g of gelatin.

[0041] Among them, the nano additives are: silica nanoparticles, zinc oxide nanoparticles, zirconia nanoparticles and silicon carbide nanofibers, wherein: silica nanoparticles 0.6g, zinc oxide nanoparticles 1.3g, zir...

Embodiment 3

[0050]The mass g array is: 25g of water-based resin, 12g of polyurethane emulsion, 13g of diatomite, 13g of rare earth, 5g of polyacrylamide, 3g of imidazoline, 0.6g of hydroxymethyl cellulose, 2g of nano additives, 7g of adsorption aids, and fungicide 2g, 0.6g film former, 0.7g defoamer, 0.8g leveling agent, 0.3g wetting agent, 0.8g dispersant, 0.6g thickener, 3g titanium dioxide and 25g deionized water.

[0051] Among them, the water-based resin is composed of polyester resin, alkyd resin, and silicone resin, wherein: 11g of polyester resin, 6g of alkyd resin and 8g of silicone resin;

[0052] Wherein, the film forming agent is a mixture of polyvinyl alcohol, povidone and gelatin, wherein: polyvinyl alcohol 0.1g, povidone 0.3g and gelatin 0.2g;

[0053] Among them, the nano additives are composed of silica nanoparticles, zinc oxide nanoparticles, zirconia nanoparticles and silicon carbide nanofibers, wherein: 0.5g of silica nanoparticles, 0.8g of zinc oxide nanoparticles, zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com