New process avoiding coarse 6063 extrusion aluminum alloy crystals

A technology with coarse grains and aluminum alloys is applied in the new process field to avoid the coarse grains of 6063 extruded aluminum alloys, which can solve the problems of coarse grains, uneven product performance, deformation, etc. effect of heat preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

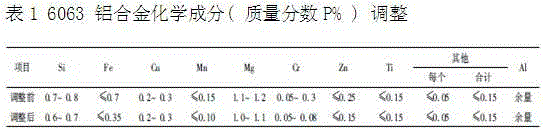

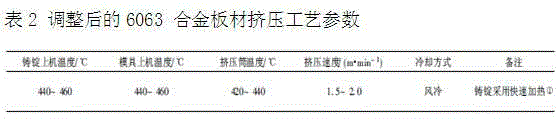

[0007] Firstly, starting from the composition of the ingot, the chemical composition adjustment plan for the large-scale ingot of 6063 aluminum alloy was formulated, as shown in Table 1. Secondly, the homogenization process, extrusion process, quenching process, and aging process were adjusted. According to different specifications, the quenching heating and holding time are different. The specific extrusion process parameters are shown in Table 2.

[0008]

[0009]

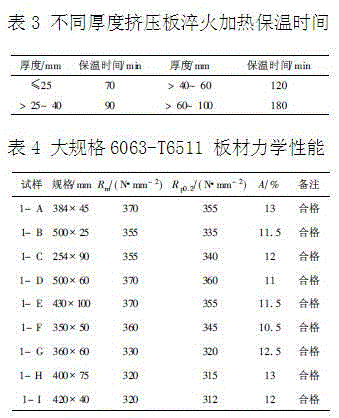

[0010] Homogenization process of 6063 aluminum alloy ingot: set temperature at 550°C; hold time for 6h~8h; cooling method, strong wind cooling to 200°C and then water cooling. Extruded plate quenching process parameters: furnace heating chamber temperature 525, holding time according to plate thickness as shown in Table 3. The statute of limitations is 175, 10h. Table 4 shows the results of product detection performance and mechanical properties after adjusting the composition and process.

[0011]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com