Eulaliopsis binata fiber used for weaving with high elongation

A technology with high elongation rate of asparagus fiber, applied in fiber processing, textile and papermaking, chemical post-treatment of fibers, etc., can solve the problems of asparagus fiber research, long time required, etc., and achieve excellent mechanical strength , high elongation at break, and good performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

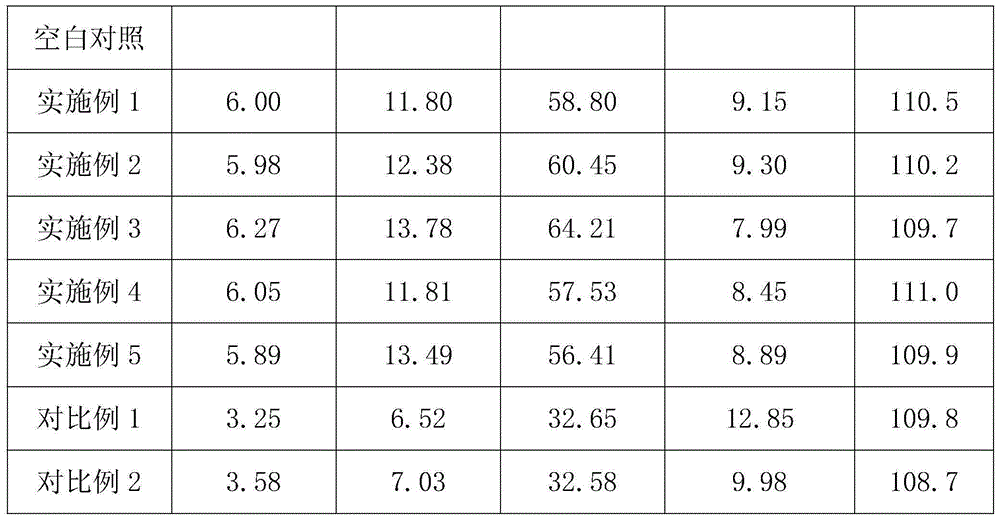

Embodiment 1

[0031] Preparation of asparagus fiber for weaving with high elongation:

[0032] (1) Preprocessing:

[0033] Picking the year-old, high-maturity Asparagus, mechanically beat the harvested Asparagus to remove impurities, and then perform pretreatment. The treatment process is: malic acid 10g / L, acetic acid 2.5g / L, time 3h, temperature 80℃, liquor ratio 1:20;

[0034] (2) Microwave treatment:

[0035] Washing the pretreated asparagus fiber with water, heating to 80°C by microwave radiation;

[0036] (3) Enzyme treatment:

[0037] Equipped with enzyme solution: alkaline pectinase 5.3g / L, laccase 0.5g / L, neutral protease 0.7g / L, cellulase 0.2g / L;

[0038] The enzyme activity of the alkaline pectinase is 350U / g, the enzyme activity of laccase is 3000u / g, the enzyme activity of neutral protease is 3000u / g, and the enzyme activity of cellulase is 2800u / g

[0039] The processing parameters are: bath ratio 1:20, time 98min, temperature 42°C;

[0040] (4) Microbial fermentation: ...

Embodiment 2

[0047] Preparation of asparagus fiber for weaving with high elongation:

[0048] (1) Preprocessing:

[0049] Pick the year-old, high-maturity asparagus, mechanically beat the harvested asparagus to remove impurities, and then perform pretreatment. The treatment process is: malic acid 12g / L, acetic acid 2g / L, time 3h, temperature 80°C ℃, liquor ratio 1:20;

[0050] (2) Microwave treatment:

[0051] Washing the pretreated asparagus fiber with water, heating to 80°C by microwave radiation;

[0052] (3) Enzyme treatment:

[0053] Equipped with enzyme solution: alkaline pectinase 5.3g / L, laccase 0.8g / L, neutral protease 0.6g / L, cellulase 0.2g / L;

[0054] The enzyme activity of the alkaline pectinase is 350U / g, the enzyme activity of laccase is 3000u / g, the enzyme activity of neutral protease is 3000u / g, and the enzyme activity of cellulase is 2800u / g

[0055] The processing parameters are: bath ratio 1:20, time 102min, temperature 40°C;

[0056] (4) Microbial fermentation:

...

Embodiment 3

[0063] Preparation of asparagus fiber for weaving with high elongation:

[0064](1) Preprocessing:

[0065] Pick the year-old, high-maturity Asparagus, mechanically beat the harvested Asparagus to remove impurities, and then perform pretreatment. The treatment process is: malic acid 11g / L, acetic acid 2.4g / L, time 3h, temperature 80℃, liquor ratio 1:20;

[0066] (2) Microwave treatment:

[0067] Washing the pretreated asparagus fiber with water, heating to 80°C by microwave radiation;

[0068] (3) Enzyme treatment:

[0069] Equipped with enzyme solution: alkaline pectinase 5.3g / L, laccase 0.7g / L, neutral protease 0.7g / L, cellulase 0.2g / L;

[0070] The enzyme activity of the alkaline pectinase is 350U / g, the enzyme activity of laccase is 3000u / g, the enzyme activity of neutral protease is 3000u / g, and the enzyme activity of cellulase is 2800u / g

[0071] The processing parameters are: liquor ratio 1:20, time 100min, temperature 41°C;

[0072] (4) Microbial fermentation:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com