Preparation method of nano-silver coating of chitosan modified fabric

A technology of chitosan modification and nano-silver, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problem of high cost, achieve the effect of cheap price, lower production cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

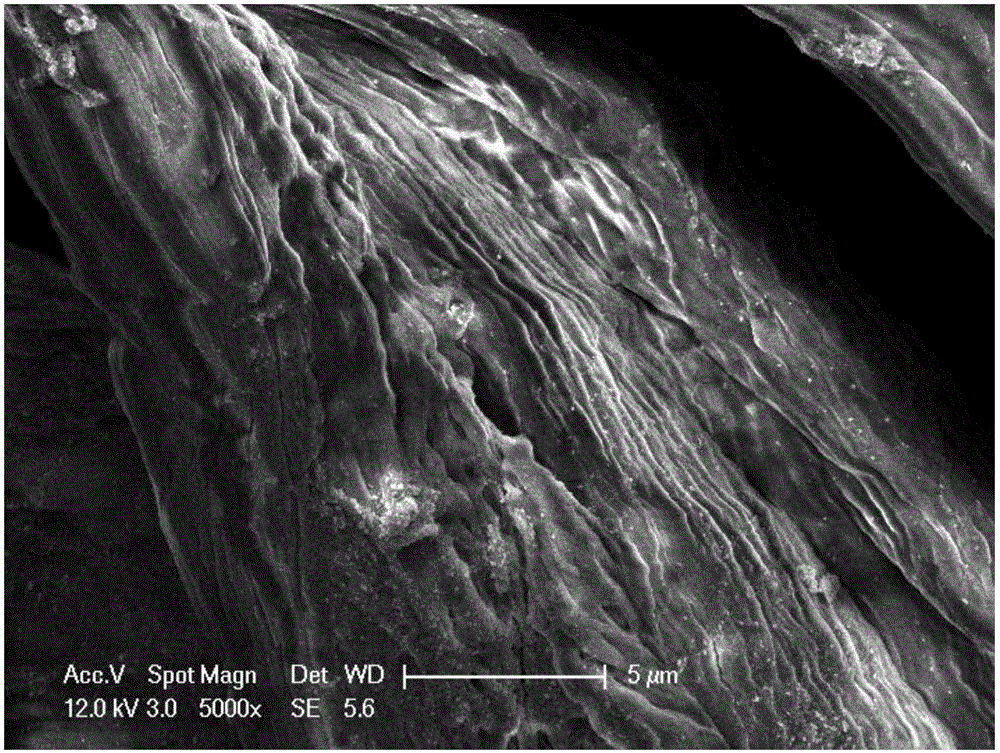

Embodiment 1

[0026] Take a 4cm×4cm cotton fabric, treat it with 0.5% NaOH solution at 60°C for 30min, rinse it with water, and dry it. The cotton fabric was dipped into 200 mL of 0.2% chitosan solution (chitosan was dissolved in 1% glacial acetic acid solution), heated and stirred at 60° C. for 60 min. Rinse in 0.5% NaOH aqueous solution for 30 minutes, rinse with clear water, and dry at 100° C. to obtain chitosan-modified cotton fabric. Immerse the chitosan-modified cotton fabric into 100mL of 0.08% silver nitrate solution, control the temperature of the water bath at 60°C and shake and stir for 30 minutes to make the fabric fully absorb silver ions, then add alkali to adjust the pH to 7-8, and react After 60 minutes, take it out for rinsing, and dry at 80° C. to obtain a yellow nano-silver cotton fabric. According to the American AATCC Test Method 100—1999 "Quantitative Test Method" to test the antibacterial performance of blank fabrics or nano-silver fabrics, the antibacterial rate aga...

Embodiment 2

[0028] Take a 4cm×4cm polyester fabric, treat it with 20% NaOH solution at 80°C for 60min, wash and dry it. This fabric is immersed in the chitosan finishing solution of 200mL (solvent is the glacial acetic acid aqueous solution of volume concentration 1%, solute is the chitosan of mass concentration 0.5%, the citric acid of 0.3%, the sodium acetate of 0.4%), 80 It was shaken in a water bath at ℃ for 120 minutes, pressed once, rinsed in 0.5% NaOH aqueous solution for 30 minutes, rinsed with water, and dried at 100 ℃ to obtain chitosan-modified polyester fabric. Immerse chitosan-modified polyester fabric into 100mL of 1% silver nitrate solution, shake and stir at 60°C for 90 minutes to make the fabric fully absorb silver ions, then add alkali to adjust the pH to 7-9, shake for 60 minutes, take out Rinse with clear water and dry at 80° C. to obtain a brown-yellow nano-silver polyester fabric. According to the American AATCC Test Method 100—1999 "Quantitative Test Method" to tes...

Embodiment 3

[0030]Take a 4cm×4cm polyester-cotton fabric, treat it with 5% NaOH solution at 80°C for 60min with a bath ratio of 1:20, wash and dry. This fabric is immersed in the chitosan solution of 200mL (solvent is the glacial acetic acid aqueous solution that volume concentration is 1%, solute is the chitosan of mass concentration 0.3%, the citric acid of 0.4%, the sodium acetate of 0.3%), 80 ℃ water bath shaking treatment for 120min, rolling treatment once, then rinsing in 0.5% NaOH aqueous solution for 30min, rinsing with clear water, and drying at 100℃ to obtain chitosan-modified polyester-cotton fabric. Immerse the chitosan-modified cotton fabric into 100mL of 0.15% silver nitrate solution, shake and stir in a water bath at 60°C for 30 minutes to make the fabric fully absorb silver ions, then add alkali to adjust the pH to 7-9, react for 60 minutes, and take out Rinse and dry at 80°C to obtain a yellow nano-silver polyester-cotton fabric. According to the American AATCC Test Meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com