Spiral steel pipe with metal liner and heating and thermal functions and manufacturing method thereof

A metal lined, spiral steel pipe technology, applied in the direction of thermal insulation protection of pipelines, heat preservation, pipeline heating/cooling, etc., can solve the problems of high temperature resistance, difficult heating of the medium in the pipe, easy aging, etc., to improve anti-corrosion and wear-resistant performance. , to avoid the loss of heat, the effect of not easy to instability and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

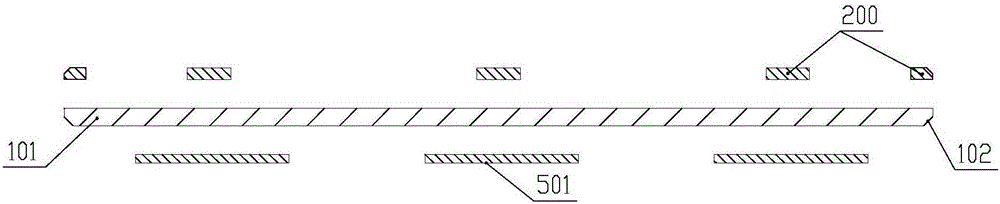

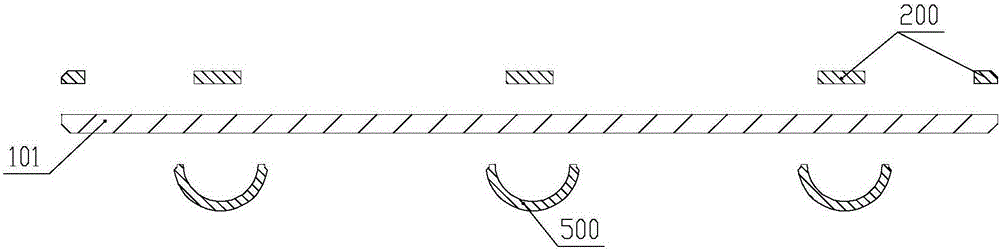

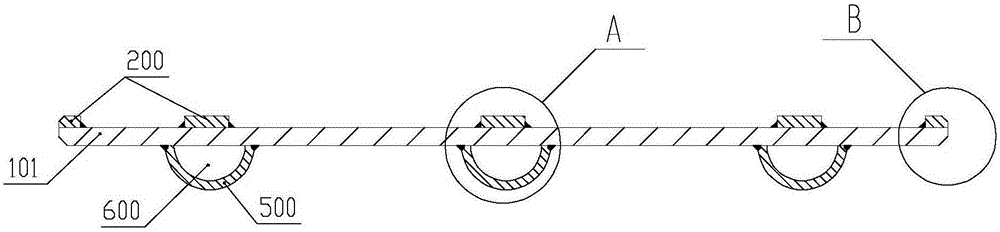

[0041] The spiral steel pipe with metal inner lining and heating and heat preservation functions of the present invention includes a pipe body 100, a plurality of metal steel strips 200 are spirally arranged on the inner wall of the pipe, and heat insulation materials are laid between adjacent metal steel strips 200 to form The thermal insulation layer 300 can effectively avoid the heat loss of the transmission medium, and the metal steel strip 200 and the thermal insulation layer 300 cover the entire inner wall of the pipe. Metal lining 400; a reinforcing ring 500 is spirally wound along the outer wall of the tube, and a spiral hollow cavity 600 is formed between the inner wall of the reinforcing ring 500 and the outer wall of the tube body 100, and a heating device 700 is arranged in the hollow cavity 600, which can Realize the function of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com