Machine tool thermal error modeling method based on multi-element projection pursuit clustering

A projection pursuit and modeling method technology, applied in the field of data processing, can solve the problems of reducing the position sensitivity of the temperature sensor, difficult to solve the temperature variable coupling, increasing modeling constraints, etc., to improve the defects of polynomial regression, shorten the The effect of high calculation time and prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

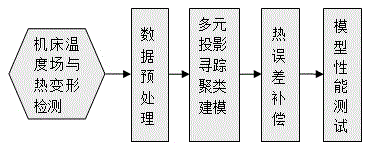

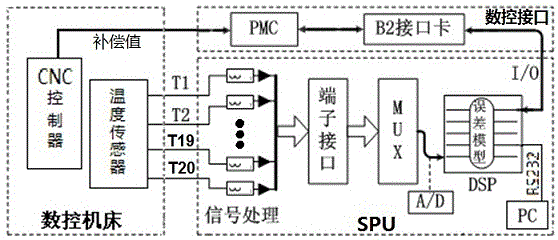

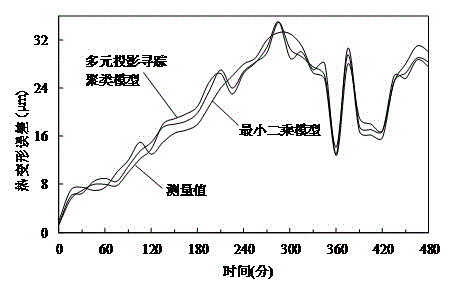

[0023] The technical process of the present invention is as figure 1 As shown, the measured temperature value of the key heat source that has a great influence on the thermal deformation of the machine tool is used as the model input, and the thermal deformation error is used as the model output to establish a multivariate projection pursuit clustering model. Select 32 samples from the experimental results of machine tool temperature field and thermal deformation detection, take the temperature values of 20 heat sources as input variables, and the thermal deformation error value as output variables, and substitute them into the multivariate projection pursuit clustering model for training to determine the model parameters . The thermal error compensation process is completed through the self-developed thermal error compensation system, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com