Method for reducing allergenicity of casein in cow milk through high hydrostatic pressure

A high static pressure and casein technology, applied in the field of milk production, achieves the effects of less damage, lower allergenicity, and is conducive to equipment maintenance and technology promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

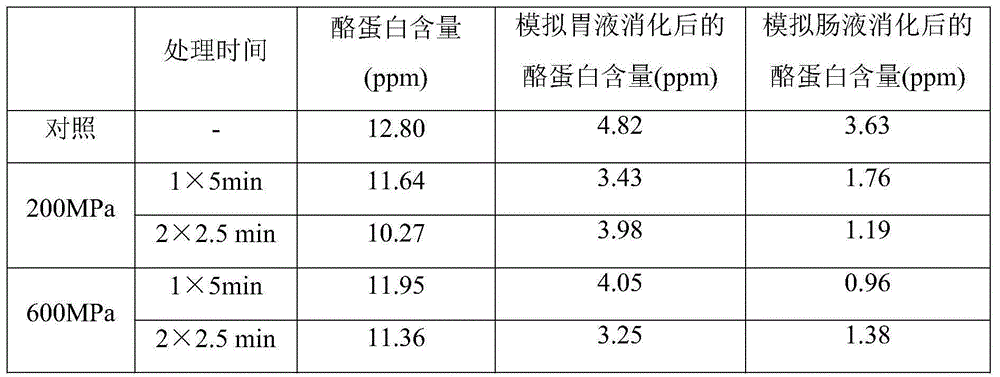

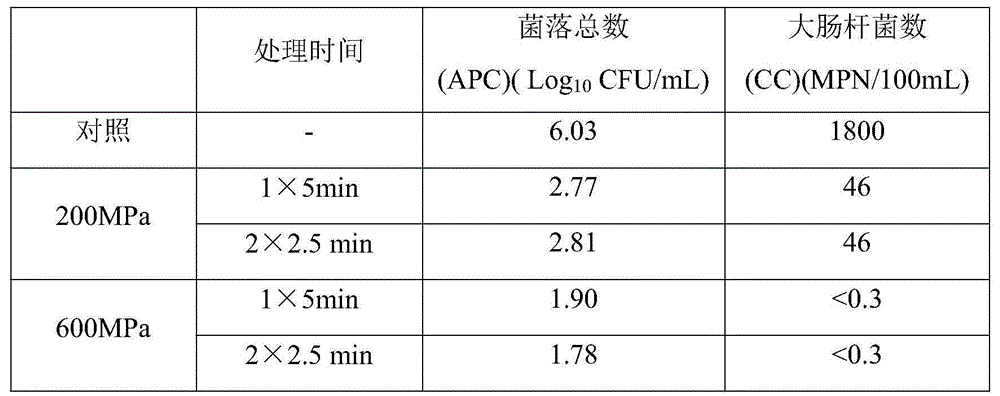

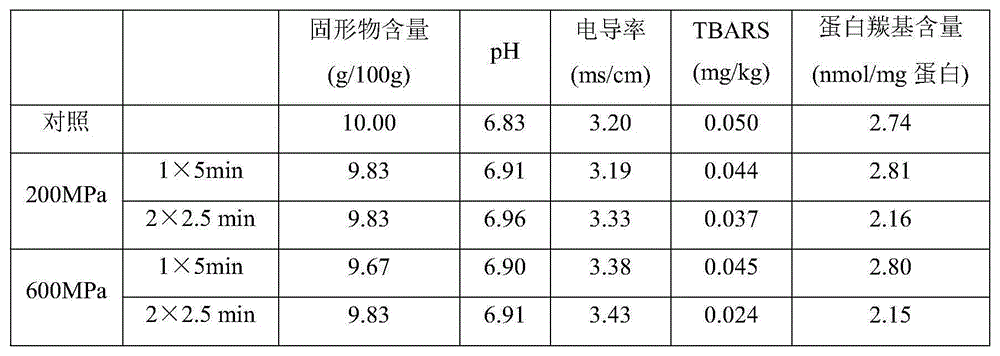

Embodiment 1

[0028] The milk is packed in "polyamide" composite "film-polypropylene" (PA / CPP) plastic bags under aseptic conditions, and vacuum packed. Fill the high-pressure container of the high-static pressure equipment with water, and control the temperature of the circulating water system at 25°C. Put the vacuum packaging bag containing milk in the material chamber of the high static pressure equipment, under the treatment pressure of 200MPa, the treatment temperature of 25°C, the cycle of high static pressure treatment time 2×2.5min, the high static pressure boost rate of 8.3MPa / min , processed under the condition of high static pressure and depressurization time of 4s to obtain sterilized milk products. The results of the high static pressure treatment in this embodiment on the antigenicity of casein in milk are shown in Table 1; the results of the effect on the bactericidal effect of milk are shown in Table 2;

Embodiment 2

[0030] The milk is packed in "polyamide" composite "film-polypropylene" (PA / CPP) plastic bags under aseptic conditions, and vacuum packed. Fill the high-pressure container of the high-static pressure equipment with water, and control the temperature of the circulating water system at 25°C. Place the vacuum packaging bag containing milk in the material chamber of the high static pressure equipment, under the treatment pressure of 600MPa, the treatment temperature of 25°C, the cycle of high static pressure treatment time 2×2.5min, and the high static pressure boost rate of 8.3MPa / min , processed under the condition of high static pressure and depressurization time of 3s to obtain sterilized milk products. The results of the high static pressure treatment in this embodiment on the antigenicity of casein in milk are shown in Table 1; the results of the effect on the bactericidal effect of milk are shown in Table 2;

Embodiment 3

[0032]The milk is packed in "polyamide" composite "film-polypropylene" (PA / CPP) plastic bags under aseptic conditions, and vacuum packed. Fill the high-pressure container of the high-static pressure equipment with water, and control the temperature of the circulating water system at 25°C. Put the vacuum packaging bag containing milk in the material chamber of the high static pressure equipment, at a processing pressure of 200MPa, a processing temperature of 25°C, a cycle of high static pressure treatment time of 1×5min, and a high static pressure boost rate of 8.3MPa / min. Treat under the condition of high static pressure and depressurization time of 4s to obtain sterilized milk products. The results of the high static pressure treatment in this embodiment on the antigenicity of casein in milk are shown in Table 1; the results of the effect on the bactericidal effect of milk are shown in Table 2;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com