Polymeric ferric sulfate reaction device

A technology of polymerized ferric sulfate and reaction device, which is applied in the direction of chemical/physical/physical chemical fixed reactors, etc., which can solve the problems of small gas-liquid contact area, low reaction efficiency, and reaction system collapse, etc., so as to prolong the service life , small impact, anti-collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

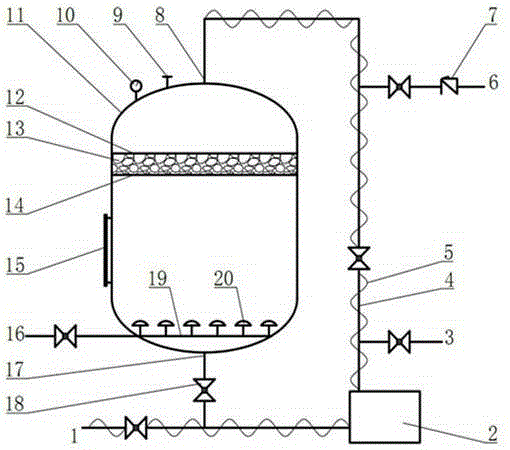

[0024] The invention provides a polyferric sulfate reaction device with high reaction efficiency. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

[0025] The polyferric sulfate reaction device comprises a reactor and a circulation pipeline, the reactor is a vertical reactor, the reactor below is provided with a base for fixing and load-bearing, and the still body 11 of the reactor is provided with an exhaust port 9, Manhole 15, feed port 8 and discharge port 17, feed port 8 is located directly above the top of the reactor, and discharge port 17 is located at the center of the bottom of the reactor. The pressure gauge 10 of the chamber pressure, the circulation pipeline is connected end to end with the feed port 8 and the discharge port 17 on the reactor, including the circulation pipeline 4, the circulation pump 2 arranged on the circulation pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com