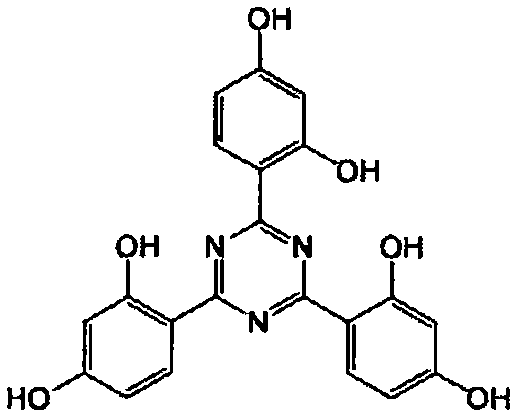

Preparation method of 2,4,6-tri(2',4'-dihydroxyphenyl)-1,3,5-triazine

A technology of dihydroxyphenyl and cyanuric chloride, which is applied in chemical recovery, organic chemistry, etc., can solve environmental pollution and other problems, and achieve the effects of avoiding environmental pollution, simple and easy-to-obtain catalysts, and simple reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

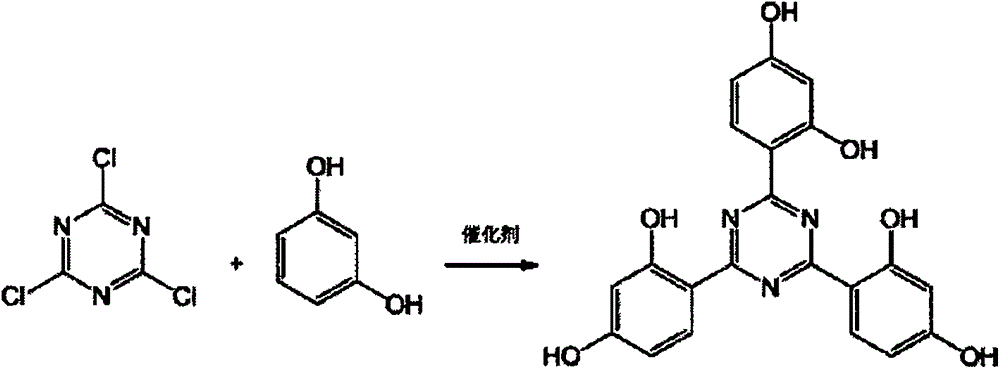

Method used

Image

Examples

Embodiment 1

[0030] Add 0.92g (5mmol) cyanuric chloride successively in 100mL there-necked flask, 20mL anhydrous tetrahydrofuran, add 1.65g (15mmol) resorcinol under stirring; Add 50wt% Fe after heating up to dissolve completely 2 o 3 ; Reaction at 80°C for 24h. The reaction liquid was cooled to room temperature, and the filtrate obtained by suction filtration was used for liquid phase analysis, and the yield of the target product was 56.42%.

Embodiment 2

[0032] Add 0.92g (5mmol) cyanuric chloride successively in the 100mL there-necked flask, 20mL anhydrous tetrahydrofuran, add 1.65g (15mmol) resorcinol under stirring; After heating up to dissolve completely, add 70wt% Fe 2 o 3 ; Reaction at 80°C for 24h. The reaction solution was cooled to room temperature, and the filtrate obtained by suction filtration was used for liquid phase analysis, and the yield of the target product was 58.33%.

Embodiment 3

[0034] Add 0.92g (5mmol) cyanuric chloride successively in 100mL there-necked flask, 20mL anhydrous tetrahydrofuran, add 1.65g (15mmol) resorcinol under stirring; Add 20wt% Fe after heating up to dissolve completely 2 o 3 ; Reaction at 80°C for 24h. The reaction solution was cooled to room temperature, and the filtrate obtained by suction filtration was used for liquid phase analysis, and the yield of the target product was 24.62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com