Preparation method for thermosetting composite

A composite material and thermosetting technology, applied in the field of preparation of thermosetting composite materials, can solve the problems of poor surface quality of composite materials, easy generation of bubbles in the molding and curing process, etc., and achieve the effect of enhanced crack resistance, high strength and reduced bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

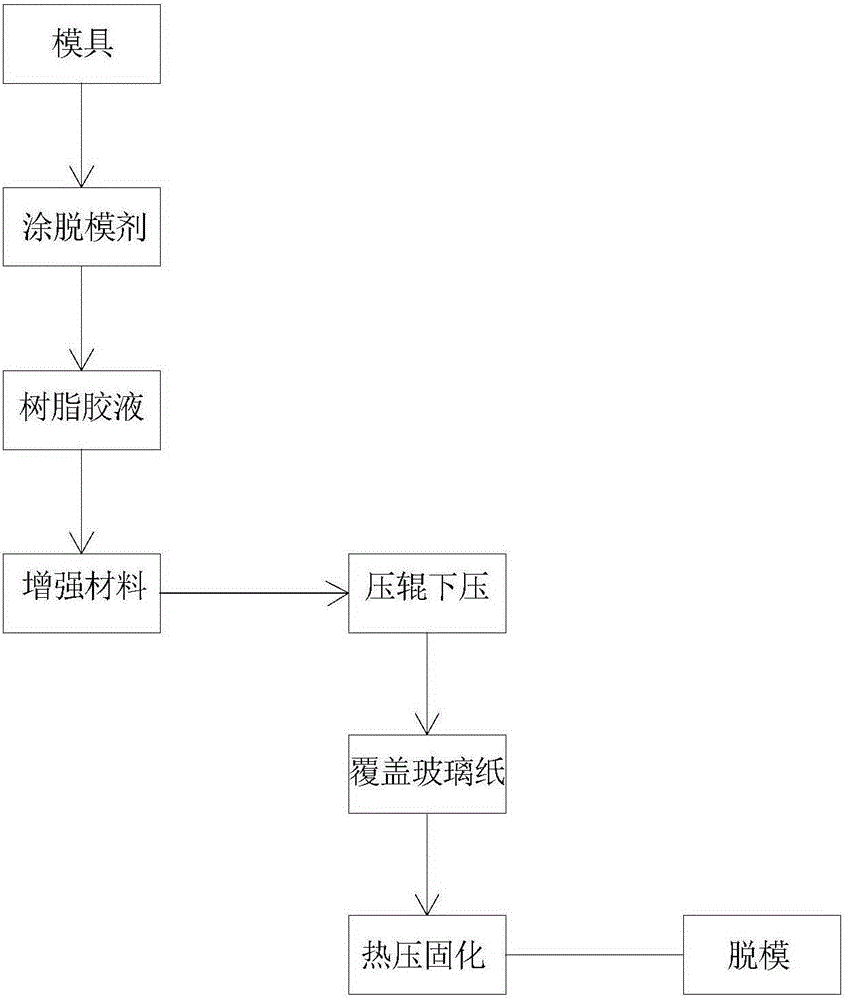

Method used

Image

Examples

Embodiment 1

[0023] The ratio of thermosetting epoxy resin: curing agent: accelerator: defoamer: filler = 100:3:3:1:5 (weight ratio), fully stir the above components at 35°C to obtain the resin glue liquid. Wherein the accelerator selected is triethanolamine, the defoamer is silicone oil, and the filler is aluminum hydroxide.

[0024] The three substances of water, sodium silicate and cork powder are fully stirred evenly at 90°C;

[0025] The glass fiber cloth is pretreated by drying at 90°C for 5 minutes;

[0026] Coat the mold release agent of above-mentioned gained on mold, form the gel coat layer after brushing the above-mentioned resin glue solution of above-mentioned gain again after brushing the resin glue solution of above-mentioned gain for the first time on the mold release agent, and in place After laying the glass fiber cloth obtained above on the gel coat layer and pressing it down with a pressure roller, pour unsaturated polyester resin on the surface of the glass fiber clo...

Embodiment 2

[0028] The ratio of thermosetting epoxy resin: curing agent: accelerator: defoamer: filler = 100:10:5:3:40 (weight ratio), fully stir the above components at 35°C to obtain the resin glue liquid. Wherein the accelerator selected is DMP-30, the defoamer is vegetable oil, and the filler is pigment.

[0029] Water, sodium silicate, and cork powder are fully stirred at 100°C;

[0030] The glass fiber cloth is pretreated by drying at 180°C for 3 minutes;

[0031] Coat the mold release agent of above-mentioned gained on mold, form the gel coat layer after brushing the above-mentioned resin glue solution of above-mentioned gain again after brushing the resin glue solution of above-mentioned gain for the first time on the mold release agent, and in place After laying the glass fiber cloth obtained above on the gel coat layer and pressing it down with a pressure roller, pour unsaturated polyester resin on the surface of the glass fiber cloth to form a surface layer, and cover the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com