Automatic laser shot device, shot point identification method and automatic shot point correction method

A technology of automatic shooting and identification methods, which is applied in the directions of weapon accessories, gun control systems, target indication systems, etc., to achieve the effect of promoting development, improving fun, and improving the level of actual combat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

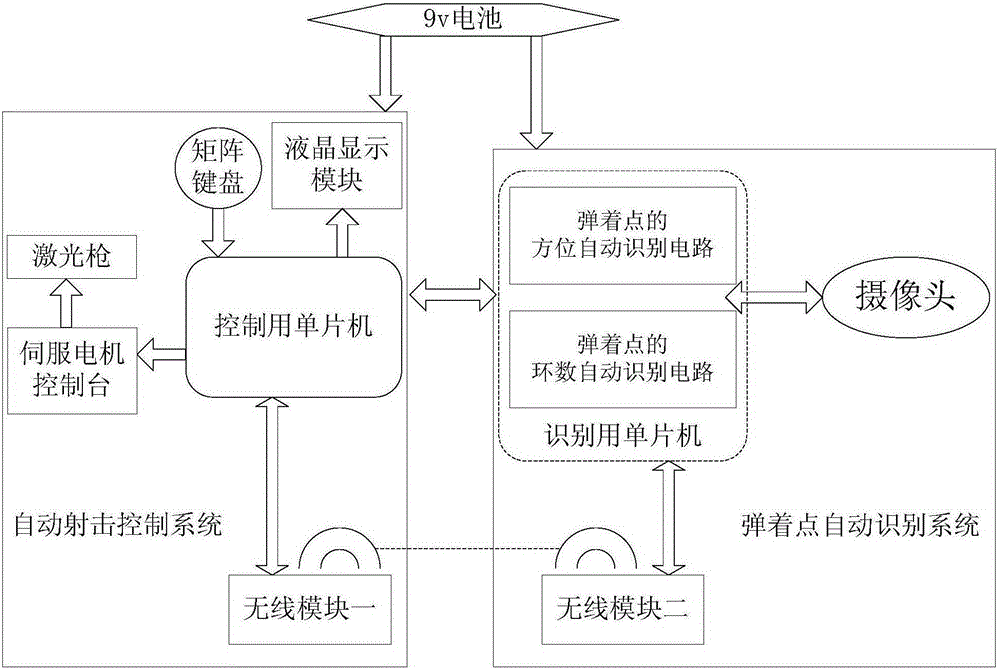

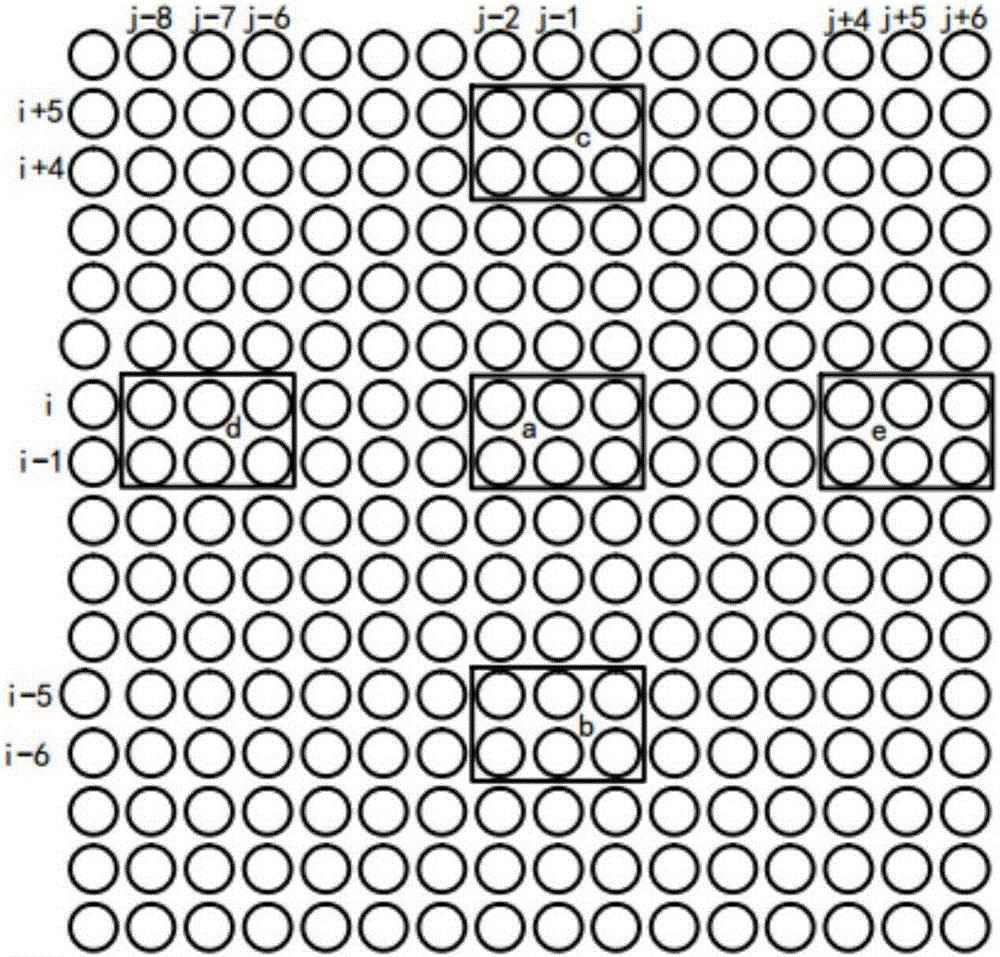

[0055] Embodiment 1, combining figure 1 and figure 2 , a laser automatic shooting device, comprising an automatic shooting control system and an automatic impact point recognition system, the automatic shooting control system comprising:

[0056] Wireless module 1, a matrix keyboard, a single-chip microcomputer connected to the matrix keyboard and controlled by it, a servo motor console connected to and controlled by the single-chip microcomputer, and a laser gun located on the servo motor console;

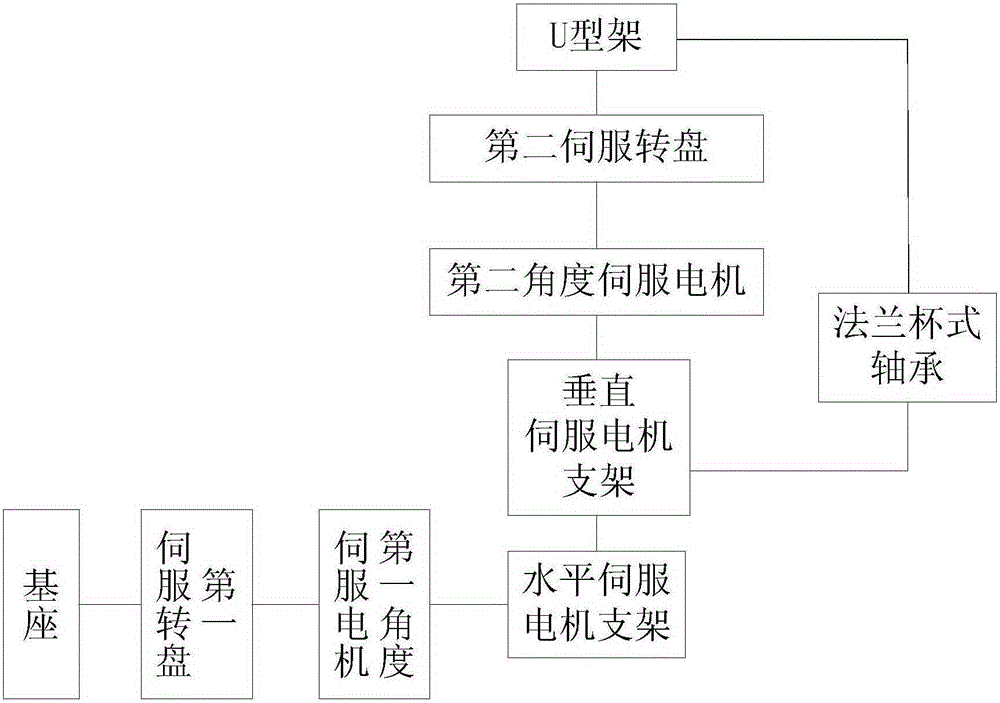

[0057] The servo motor console includes a base, a first angle servo motor, a second angle servo motor, a horizontal servo motor bracket, a vertical servo motor bracket, a U-shaped frame, a first servo turntable, a second servo turntable and a flange cup type Bearings, the first angle servo motor is fixed on the horizontal servo motor bracket, the output shaft of the first angle servo motor is connected with the first servo turntable with interference fit, the first servo turntab...

Embodiment 2

[0063] Embodiment 2: A kind of laser automatic shooting device as described in embodiment 1, automatic shooting control system also includes liquid crystal display module, is used for reporting target, comprises display chest ring target, the ring number of impact point, the bearing of impact point.

Embodiment 3

[0064] Embodiment 3: a kind of laser automatic shooting device as described in embodiment 1, described laser gun comprises the laser modulation tube that connects in sequence, laser emission tube drive circuit, laser emission tube and electromagnetic relay; Automatic shooting control system sends a The control signal is given to the electromagnetic relay, so that the normally open contact of the electromagnetic relay is closed, and the driving circuit of the laser emitting tube is connected, and the laser beam is emitted to the chest ring target.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com