Solution chemistry automatic control device used in corrosion process of iron and alloy of iron and use method of solution chemistry automatic control device

A technology of automatic control device and corrosion process, applied in measurement devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., can solve problems such as low experimental efficiency, high operating costs, and differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

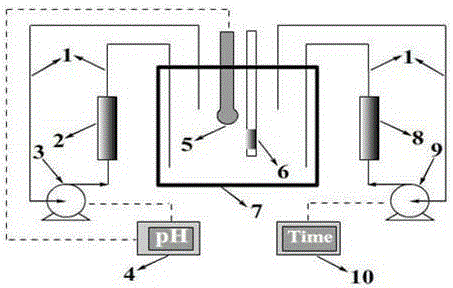

[0028] Such as figure 1 The resulting principle of the automatic control system of the present invention is illustrated. This system includes two parts: pH automatic control module and automatic control of ferric ion / ferrous ion concentration:

[0029] The pH automatic control module is used to realize the automatic control of pH during the corrosion process of iron and its alloys; the stainless steel conduit (1) is used to connect the liquid container (7), the ion exchange column (2) and the steady flow pump (3) in sequence; The pH probe (5) is used to monitor the pH of the solution in the liquid container (7); the pH controller (4) is used to set the pH range, monitor the pH of the solution in the liquid container (7) in real time, and send commands to control the steady flow pump ( 3) on / off, when the pH of the solution in the liquid container (7) was within the set range, the steady flow pump was in a closed state; when the pH of the solution in the liquid container (7) w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com