Method for refining long chain dicarboxylic acid in n-alkane fermentation solution

A technology for long-chain dibasic acid and n-alkane, which is applied in the field of micro-channel refining for purifying long-chain dibasic acid, can solve the problem of raw material purity, low chromaticity requirements, solvent recycling, and long-chain dibasic acid particle entrainment. The problem of large amount of soluble protein can improve the repeatability of product quality, avoid local supersaturation, and reduce the amount of soluble protein.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

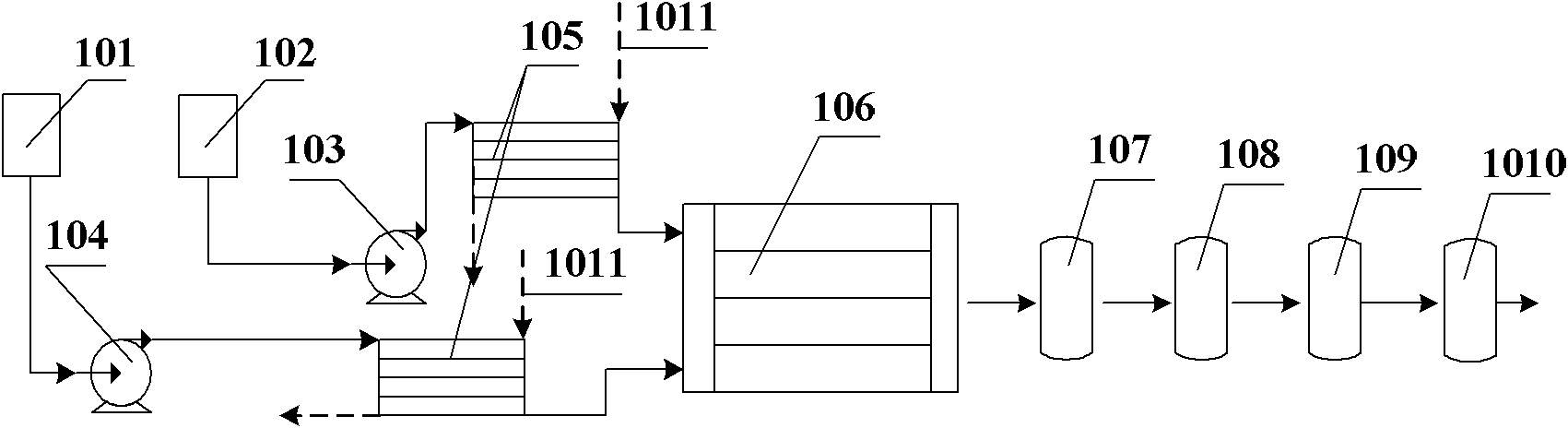

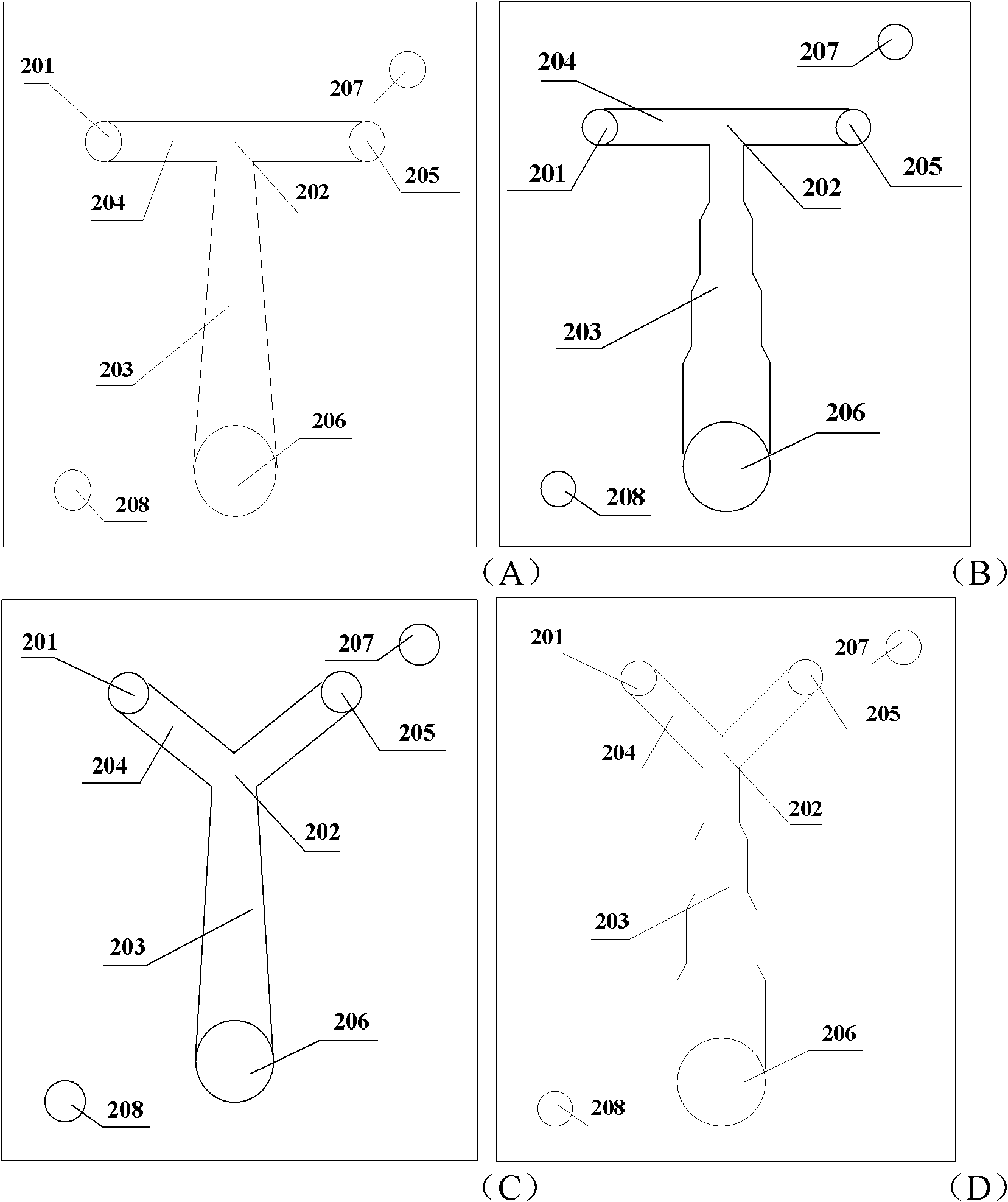

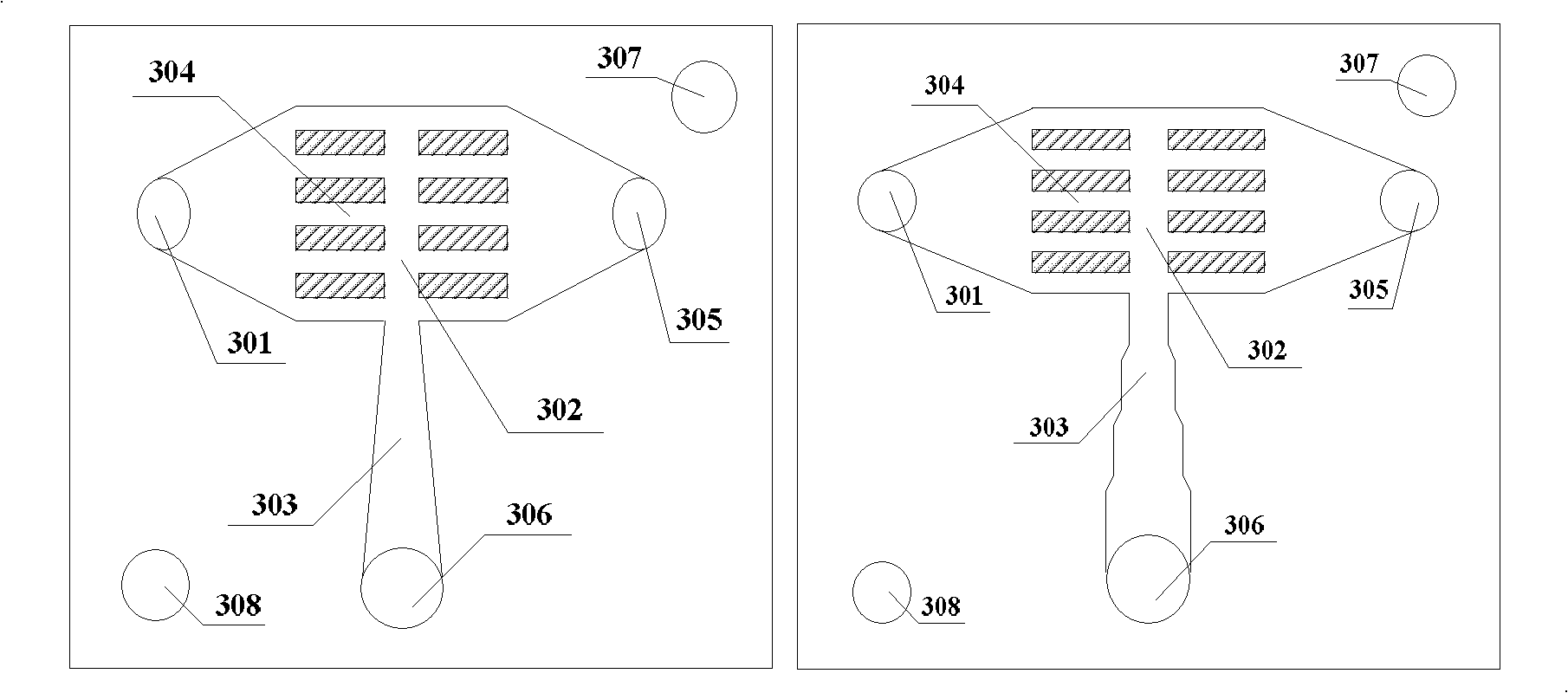

[0034] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention. The present invention is relatively familiar to those skilled in the field of microreactor or microchemical industry: the characteristic size of the channel of the microreactor involved in the present invention is on the order of micron to millimeter; what actually relates to is a liquid-liquid two-phase fluid in the microchannel Mixing, mass transfer and reaction processes. The difference is that the present invention provides a novel microchannel reactor structure, which can quickly mix the two reaction materials of the pretreated normal alkane fermentation liquid and acid liquid evenly, and the solid sediment in the product does not block the channel, and the resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com